Photolithography method

A photolithography and photoresist technology, applied in the field of photolithography, can solve problems such as difficulty in achieving the expected shape, and the optical diffraction effect cannot be 100% anisotropic.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

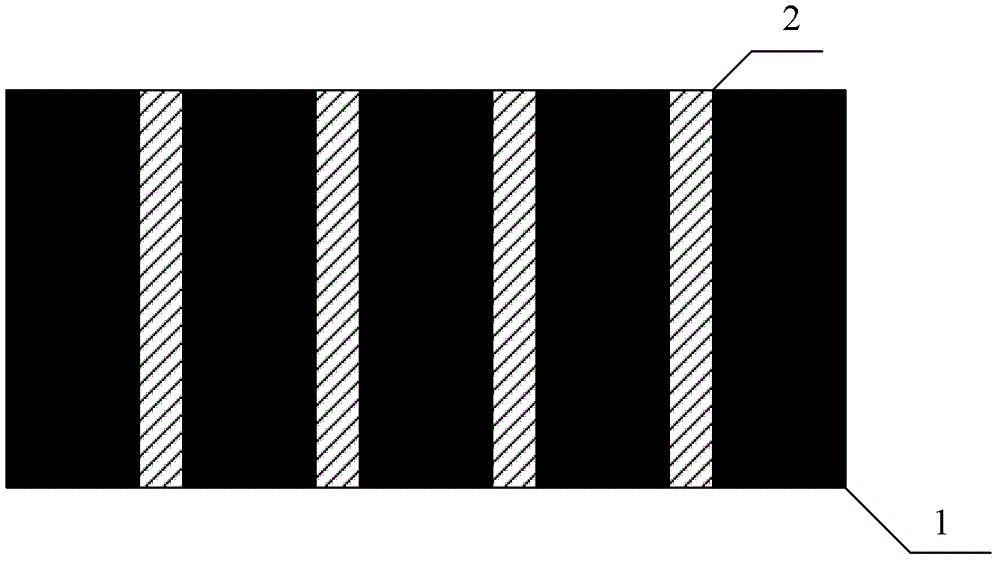

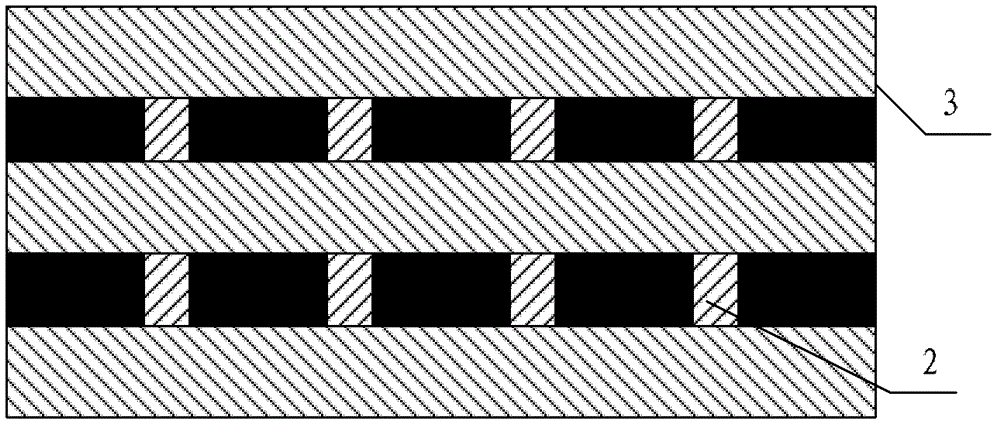

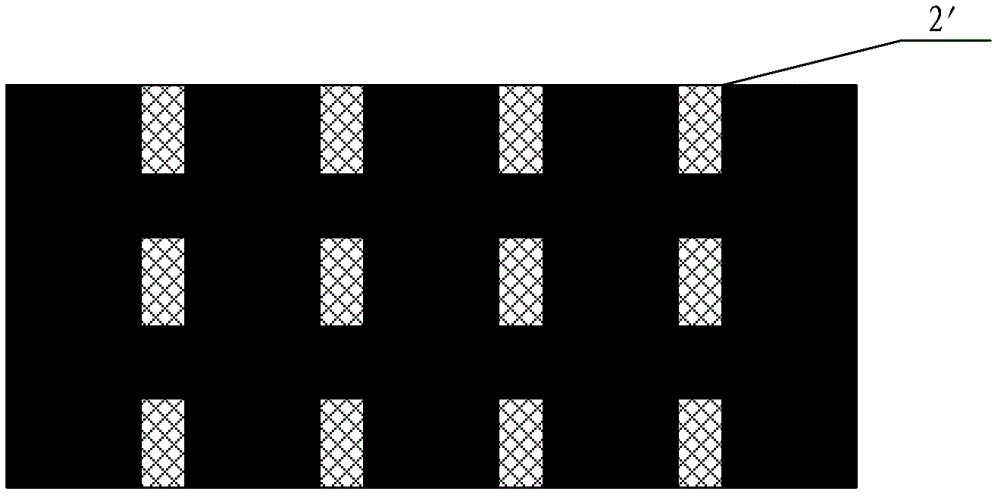

[0012] Such as Figure 2a As shown, on the semiconductor layer 21 to be etched (such as the polycrystalline gate layer), the first strip photoresist layer 22 is first formed by spin coating lithography or screen printing, and the first strip photoresist layer 22 is The resist layer 22 is subjected to freezing treatment ( Figure 2b ); Then form the second stripe photoresist layer 23 on the first stripe photoresist layer 22, the stripes of the second stripe photoresist layer 23 are orthogonal to the stripes of the first stripe photoresist layer 22, as Figure 2c As shown, and the thickness of the second stripe photoresist layer 23 is greater than the thickness of the first stripe photoresist layer 22, Figure 2d fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com