A kind of electro-optic crystal thin film, preparation method and electronic component

A technology of electro-optic crystals and thin films, which is applied in the direction of optical components, instruments, light guides, etc., can solve the problems of thin film layer damage and etching processing difficulties, and achieve the effect of improving etching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

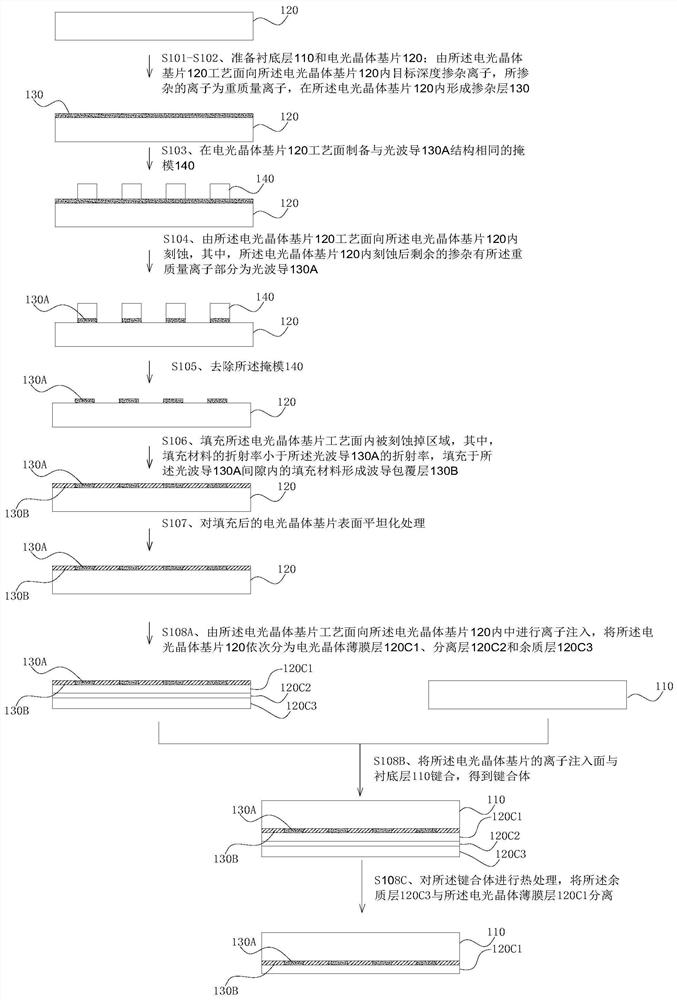

[0033] see figure 1 , Embodiment 1 of the present application provides a method for preparing an electro-optic crystal thin film, comprising the following steps:

[0034] Step 101 , preparing the substrate layer 110 and the electro-optic crystal substrate 120 .

[0035] The substrate layer 110 in the embodiment of the present application may be a single-layer substrate or a composite substrate, which is not limited in the present application, wherein the materials of each substrate in the composite substrate may be the same or different. Applications are not limited to this either. The substrate layer 110 can be made of materials such as lithium niobate, lithium tantalate, quartz, silicon, sapphire, SOI, diamond, silicon carbide, silicon nitride, gallium arsenide, or indium phosphide, which is not limited in this application.

[0036] The electro-optic crystal substrate 120 in the embodiment of the present application refers to the basic material with a certain thickness for p...

Embodiment 2

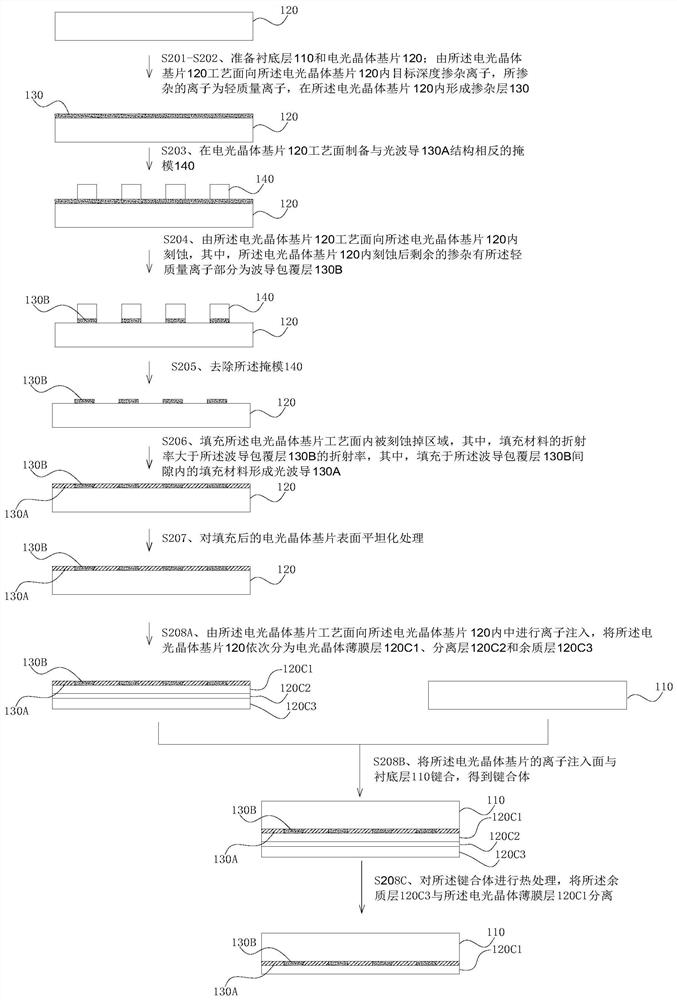

[0095] Embodiment 2 is basically the same as the above-mentioned Embodiment 1, the difference is that the ions doped from the electro-optic crystal substrate process to the target depth in the electro-optic crystal substrate in the embodiment 2 of the present application are light-weight ions. The preparation method provided in Example 2 is described.

[0096] see figure 2 , Embodiment 2 of the present application provides a method for preparing an electro-optic crystal thin film, comprising the following steps:

[0097] Step 201 , preparing the substrate layer 110 and the electro-optic crystal substrate 120 .

[0098]Step 202, using the electro-optic crystal substrate process to deeply dope ions toward the target in the electro-optic crystal substrate, the doped ions are light-weight ions, and form a doped layer 130 in the electro-optic crystal substrate 120, Wherein, the refractive index of the portion of the electro-optic crystal substrate doped with the light-mass ion i...

Embodiment 3

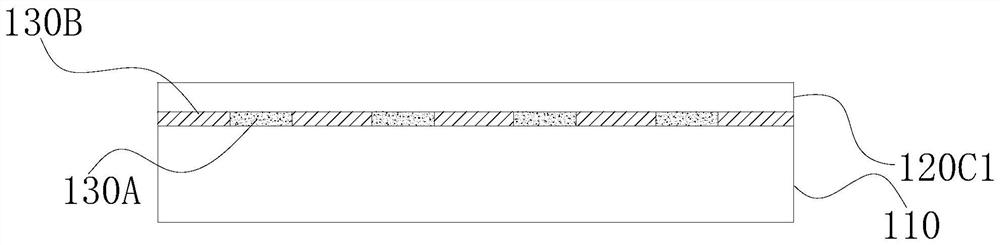

[0114] see image 3 Embodiment 3 of the present application provides an electro-optic crystal thin film, which can be prepared by the preparation method provided in Embodiment 1 above. The prepared electro-optic crystal thin film includes an electro-optic crystal thin film layer 120C1 and a substrate layer 110. The electro-optic crystal thin film layer 120C1 includes a doped region, wherein the doped ions in the doped region are heavy mass ions, the doped region forms an optical waveguide 130A, and the gap of the optical waveguide 130A is filled with a filling material to form a waveguide cladding layer 130B, the top surface of the optical waveguide 130A is on the same level as the top surface of the electro-optic crystal film layer 120C1, wherein the refractive index of the portion doped with the heavy mass ions in the electro-optic crystal film layer 120C1 is greater than that of the electro-optic crystal film layer The layer 120C1 is not doped with the refractive index of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com