A kind of anion exchange membrane based on hexamethylenetetramine salt and preparation method thereof

A technology of hexamethylene tetramine salt and anion exchange membrane is applied in the field of hexamethylene tetramine salt-based anion exchange membrane and its preparation, which can solve the problem of hindering commercial application of anion exchange membrane, low thermal and chemical stability , affecting battery performance and other issues, to achieve the effect of simple and easy preparation method, good mechanical properties and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

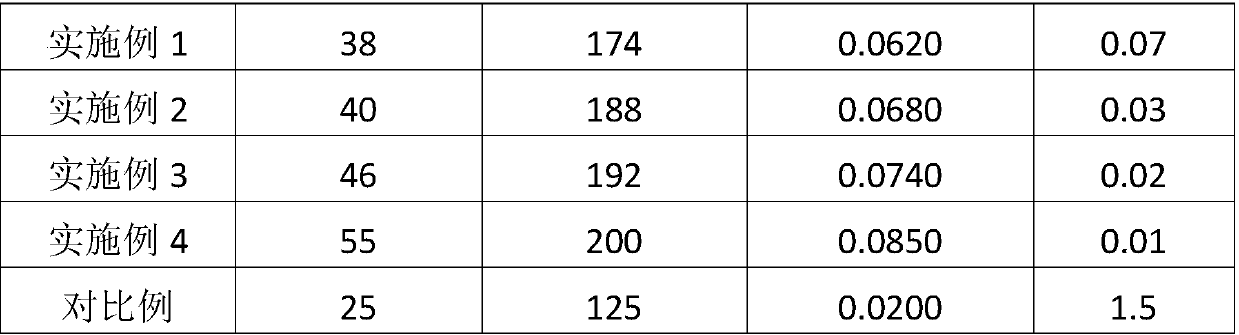

Examples

Embodiment 1

[0027] A preparation method based on hexamethylenetetramine salt anion exchange membrane, comprising the steps of:

[0028] 1) Preparation of epoxy-substituted hexamethylenetetramine salt: dissolve 10 g of hexamethylenetetramine and 27 g of epichlorohydrin in 90 g of ethanol, reflux at 40°C for 6 hours, spin at 50°C Remove the solvent by evaporation, wash with a mixed solvent for 3 times, and then remove the solvent by rotary evaporation at 50°C; the mixed solvent is a mixture formed by mixing ethanol and ether in a mass ratio of 3:7;

[0029] 2) Preparation of base film: 3 g of epoxy-substituted hexamethylenetetramine salt and 10 g of polyurethane prepared in step 1) were dissolved in 30 g of dimethyl sulfoxide, stirred and reacted at 70° C. for 6 hours, and then Settled out in acetone, filtered, washed with water and ethanol three times respectively, and dried in a vacuum oven at 60°C for 12 hours;

[0030] 3) Ion exchange: soak the polymer film prepared in step 2) in a 5% ...

Embodiment 2

[0034] A preparation method based on hexamethylenetetramine salt anion exchange membrane, comprising the steps of:

[0035] 1) Preparation of epoxy-substituted hexamethylenetetramine salt: dissolve 10 g of hexamethylenetetramine and 28 g of epichlorohydrin in 100 g of chloroform, reflux at 45°C for 7 hours, spin at 55°C Remove the solvent by evaporation, wash with a mixed solvent for 4 times, and then remove the solvent by rotary evaporation at 55°C; the mixed solvent is a mixture formed by mixing ethanol and ether in a mass ratio of 4:7;

[0036] 2) Preparation of base film: dissolve 3.3 g of epoxy-substituted hexamethylenetetramine salt and 10 g of polyurethane in 35 g of N-methylpyrrolidone prepared in step 1), and stir and react at 74°C for 7 hours , precipitated in acetone, filtered, washed with water and ethanol for 4 times respectively, and dried in a vacuum oven at 70°C for 14 hours;

[0037] 3) Ion exchange: soak the polymer film prepared in step 2) in a 7% sodium hy...

Embodiment 3

[0041] A preparation method based on hexamethylenetetramine salt anion exchange membrane, comprising the steps of:

[0042] 1) Preparation of epoxy-substituted hexamethylenetetramine salt: 10 g of hexamethylenetetramine and 29 g of epichlorohydrin were dissolved in 120 g of carbon tetrachloride, and after reflux reaction at 52° C. for 8 hours, at 57 The solvent was removed by rotary evaporation at ℃, and then washed 5 times with a mixed solvent, and then the solvent was removed by rotary evaporation at 58 °C; the mixed solvent was a mixture formed by mixing ethanol and ether in a mass ratio of 3.5:7;

[0043] 2) Preparation of base film: dissolve 3.7 g of epoxy-substituted hexamethylenetetramine salt and 10 g of polyurethane prepared in step 1) in 37 g of N,N-dimethylformamide, and stir at 77°C After reacting for 8 hours, it was precipitated in acetone, filtered, washed with water and ethanol for 5 times respectively, and then baked in a vacuum oven at 76°C for 17 hours;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com