Full-digital constant-temperature water-cooling control system for high-pressure high-capacity IEGT (Injection Enhanced Gate Transistor) converter

A water-cooling system and control system technology, applied in the direction of temperature control using electric methods, can solve the problems of large cooling water flow, low detection accuracy, waste of power consumption, etc., and achieve high automation, strong anti-interference performance, and layout simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

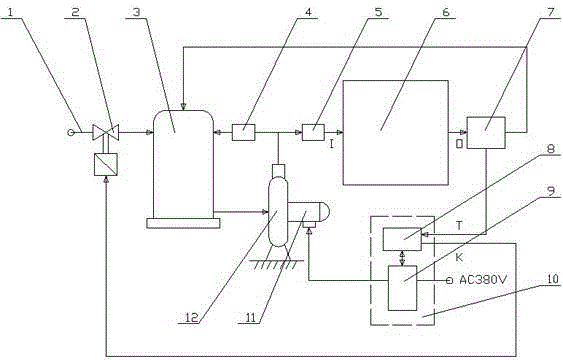

[0025] like figure 1 As shown, the high-voltage and large-capacity IEGT converter full-digital constant-temperature water-cooling control system of the embodiment of the present invention includes a main water inlet pipe 1, a solenoid valve 2, a liquid storage tank 3, an overflow valve 4, a one-way valve 5, and an IEGT converter Water cooling system 6, digital temperature transmitter 7, constant temperature cooling control cabinet 10 composed of constant temperature digital controller 8 and power supply and speed regulating unit 9, water pump 12 and its motor 11. The liquid storage tank 3 , the water pump 12 , and the water cooling system 6 of the IEGT converter are sequentially connected through pipelines to form a cooling water circulation system of the IEGT converter.

[0026] The main water inlet pipe 1 is to receive the treated cooling water, and the cooling water is connected to the liquid storage tank 3 through the solenoid valve 2 through this pipe for use by the conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com