Method for preparing titanium dioxide nanofiber ultraviolet light dependent resistor

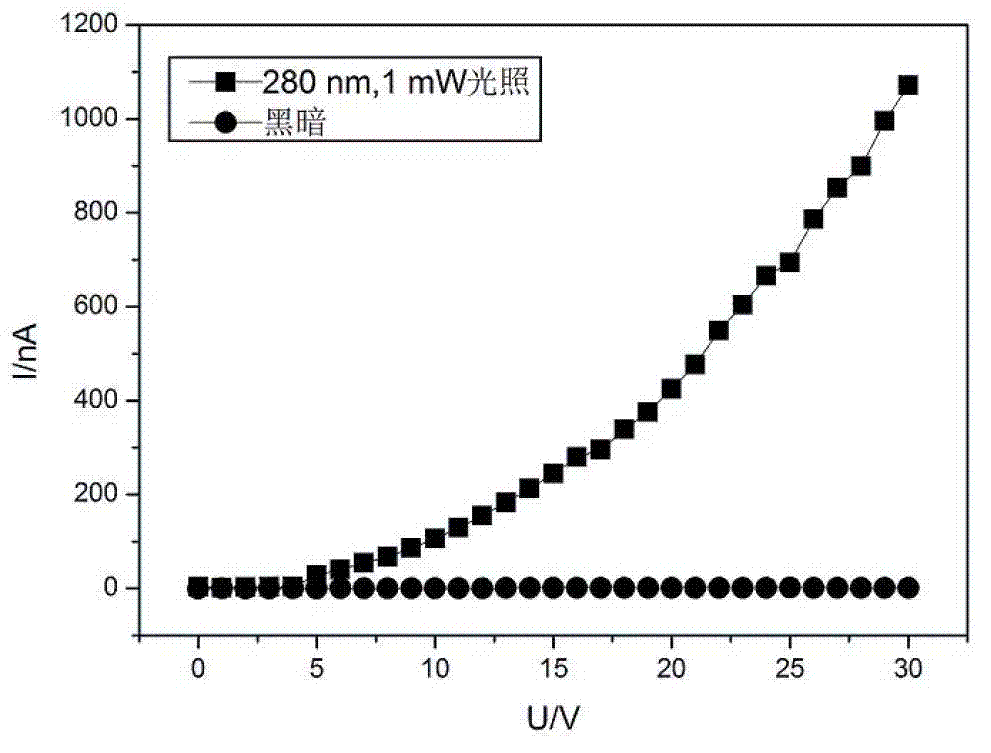

A nanofiber and titanium dioxide technology, which is applied in the manufacture of circuits, electrical components, and final products, can solve the problems of low responsiveness, dark current, and high toxicity of photoresistors, and achieve the effects of large market potential, low cost, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

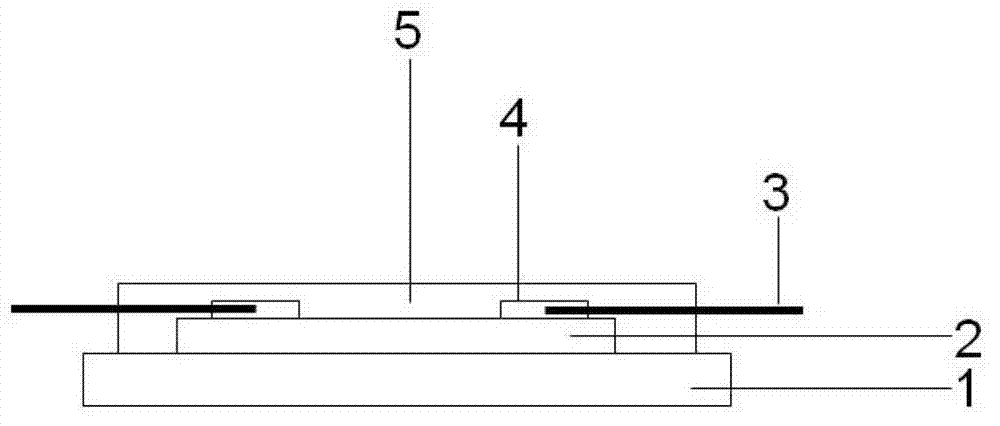

[0017] This embodiment includes three process steps of preparation of nanofiber film, preparation of pure nanofiber film and photoresistor assembly, the specific method is:

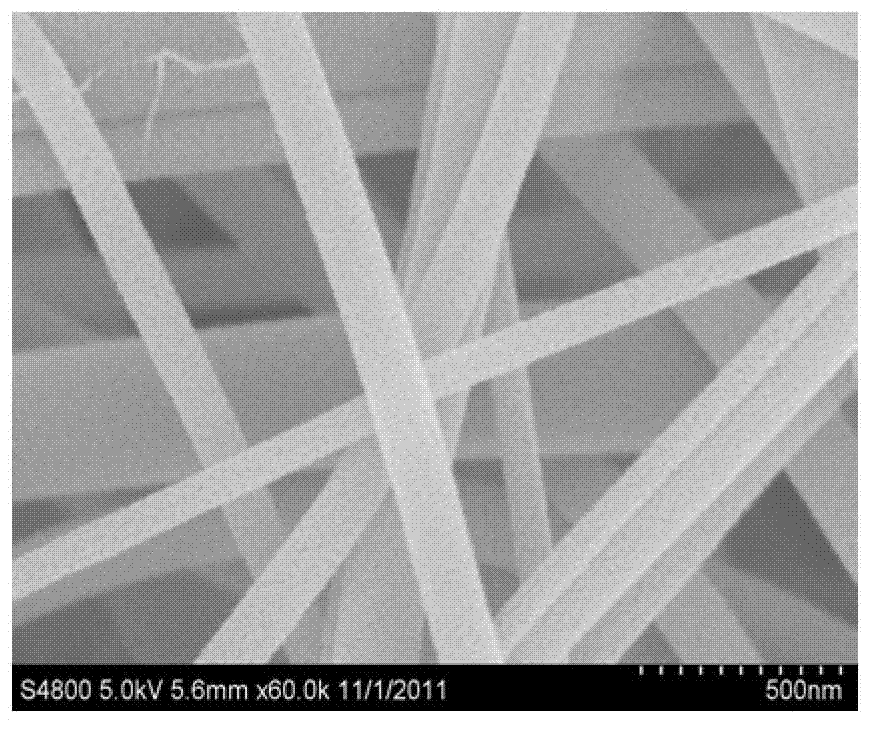

[0018] (1) Preparation of TiO by electrospinning 2 / PVP nanofiber film, first prepare the electrospinning precursor solution, mix 0.6 g of polyvinylpyrrolidone (PVP) with 6 g of tetrabutyl titanate, 8.16 g of ethanol and 4.2 g of acetic acid, and fully stir with a magnetic stirrer until Until the solution is uniform and transparent; then prepare TiO by electrospinning technology 2 / PVP composite nanofiber film, draw 4 ml of the prepared solution with a disposable dropper, drop it into a 10 ml syringe, connect the needle tip of the syringe to the positive pole of the high-voltage power supply, and connect the aluminum foil to the negative pole of the high-voltage power supply and place it 15 cm below the needle tip as a receiving Pole, turn on the high-voltage power supply, start spinning after adjusting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com