Double-zone multistage electrostatic dust collector with charged cold anode and application method thereof

A technology of electrostatic precipitator and charging area, which is applied in the field of dual-zone multi-stage electrostatic precipitator, can solve the problems of high specific resistance dust dust removal effect, etc., to eliminate adverse effects, reduce specific resistance value, and reduce current surface density value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

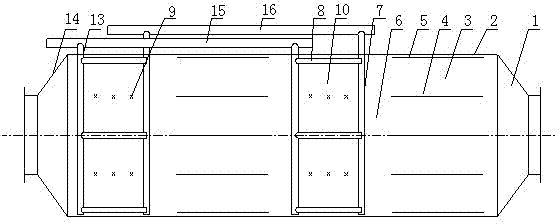

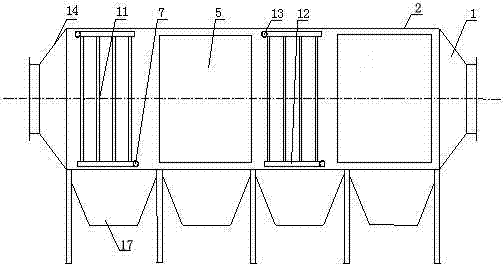

[0026] A dual-zone multi-stage electrostatic precipitator with cold pole charging, such as figure 1 and figure 2 As shown, it includes an air intake box 14, an air outlet box 1, a housing 2, and two dust removal sections 6 arranged between the air inlet box 14 and the air outlet box 1. The dust removal section 6 is composed of a dust collection area 3 and a charging area 10 , wherein the dust collecting area 3 is made up of the plate-plate channel that the anode plate 5 and the cathode plate 4 are arranged oppositely, and the charging area 10 is made up of the anode tube grid row 11 and the cathode wire grid row 9, and the anode tube grid row 11 It is a row of equidistantly arranged cold liquid pipes, and the cathode wire grid row 9 is a prickly wire arranged parallel to the cold liquid pipes. One end of the cold liquid pipe is connected to the liquid supply header 8, and the other end is connected to the liquid return header 12 connected, each liquid supply header 8 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com