Automatic cast receiving method for rollover casting machine and receiving mechanical arm thereof

A technology of pouring machines and manipulators, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of external sand core scattering, safety hazards, scalding operators, etc., to eliminate safety hazards, facilitate installation and debugging, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to describe in detail the technical content, structural features, achieved goals and effects of the present invention, specific implementation methods are given and described with accompanying drawings.

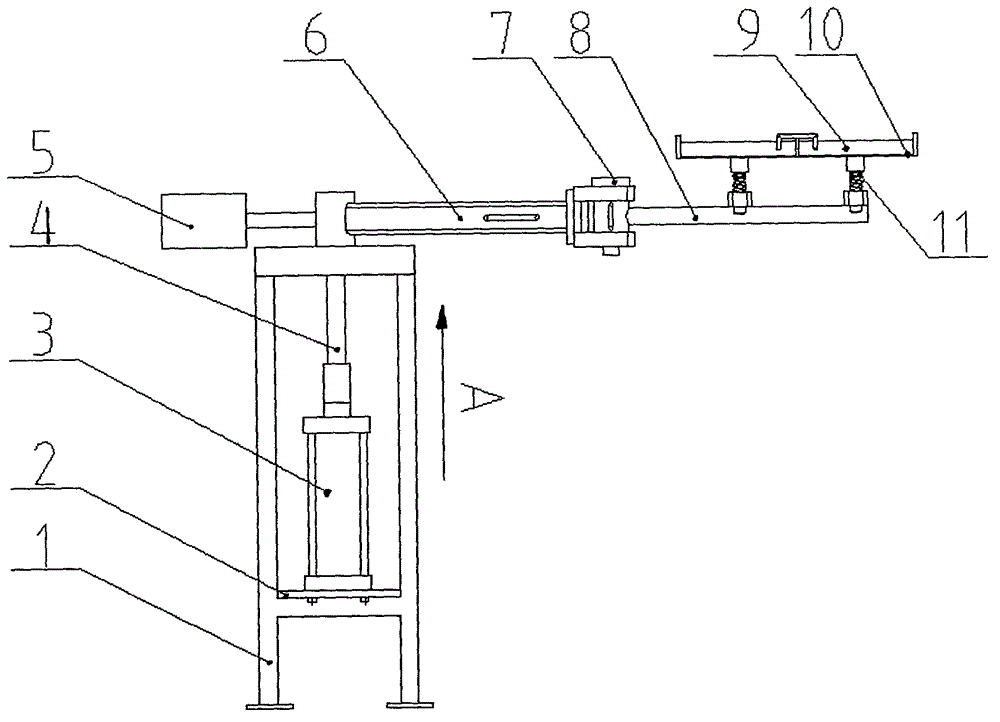

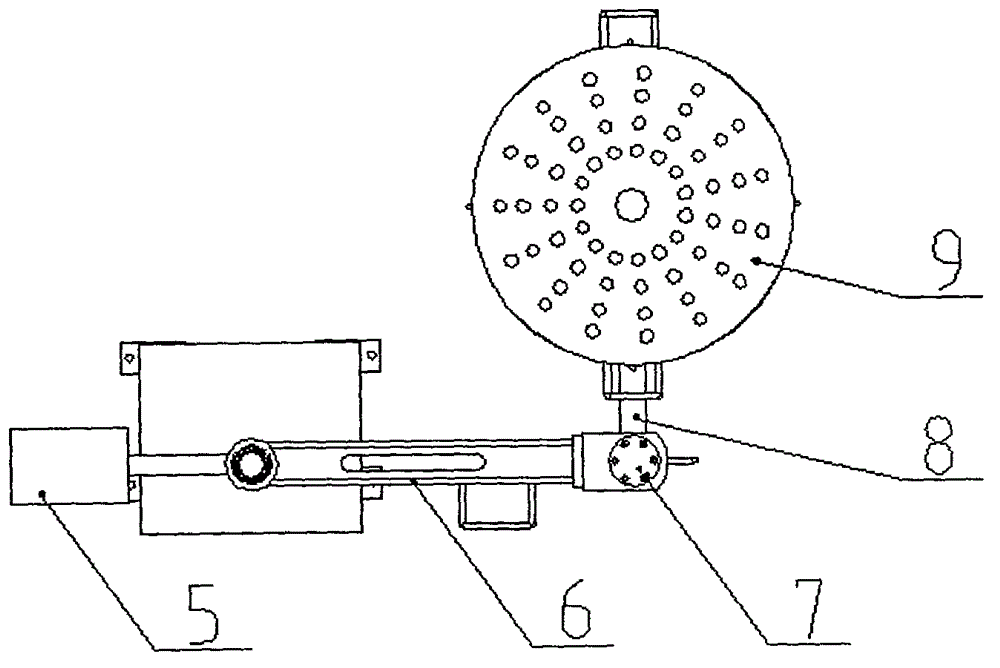

[0011] refer to figure 1 , figure 2 , the present invention is used for the automatic pick-up casting method of flip pouring machine is: when flip pouring machine pours, after mold opening, earlier the mechanical arm that comprises main arm, secondary arm is stretched into the inside of flip pouring machine through rotation, and The disc on the auxiliary arm is aligned with the position of the casting; then the driving device is controlled to drive the mechanical arm to rise automatically and the casting is picked up by the disc, and then the driving device is controlled to drive the mechanical arm to automatically descend, and the mechanical arm is rotated outward to automatically lift the casting take out.

[0012] As mentioned, the pick-up manipulator us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com