Fully-automatic bag making, filling and sealing machine filling non-polyvinyl chloride (PVC) membrane transfusion soft bag from shoulder

An infusion soft bag, fully automatic technology, applied in the directions of automatic packaging control, packaging sealing/fastening, packaging, etc., can solve the problems of solid particles mixed into the liquid medicine, occupying a large space, difficult debugging and maintenance, etc., to achieve compact structure, Small footprint and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

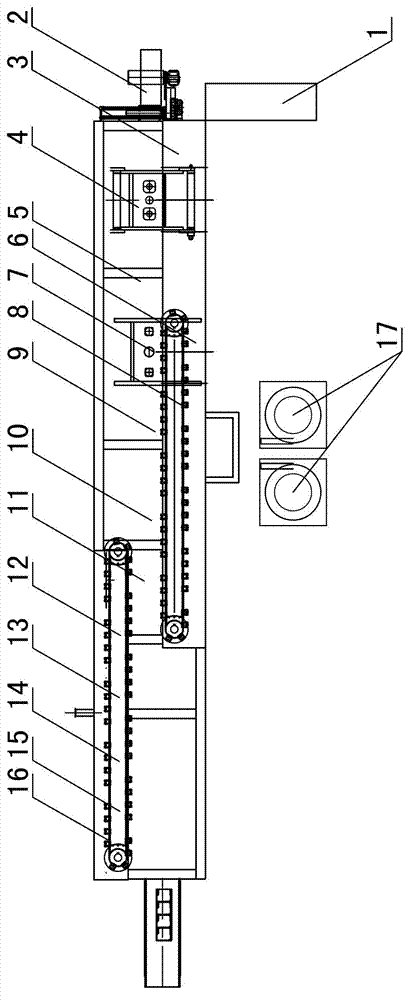

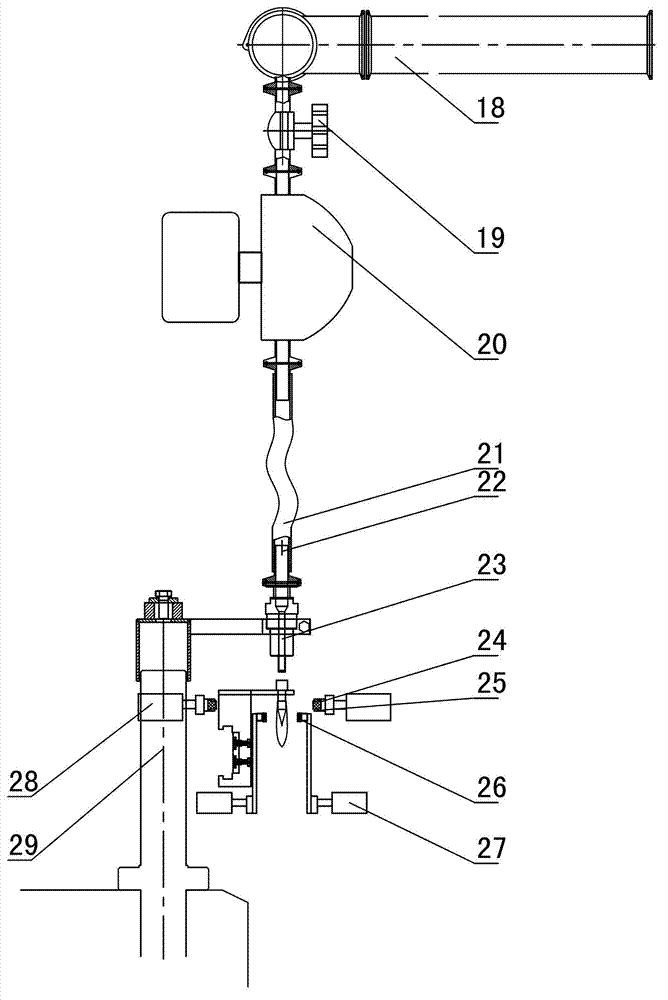

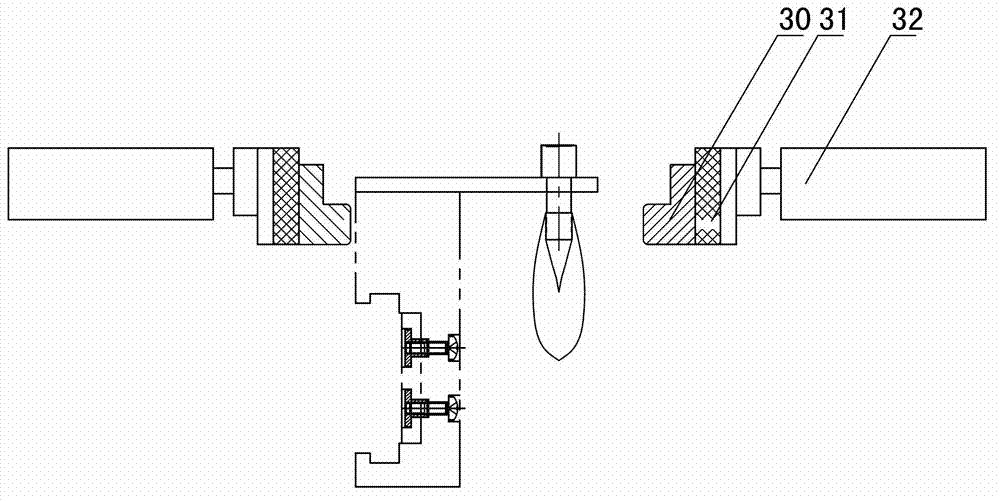

[0019] Figure 1~5 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~5 The present invention is described further:

[0020] like figure 1 Shown is a schematic diagram of the structure of the present invention, the present invention is mainly composed of three parts: frame 3 and the bag making device and potting device placed on the frame 3 . The power distribution cabinet 1 is placed outside the frame 3 . The bag making device includes a film loading mechanism 2 , a printing mechanism 4 , a film pulling mechanism 5 , a preheating mechanism 6 , a bag making mechanism 7 , a first circular transfer assembly 8 , a welding mechanism 9 , a shaping mechanism 10 and an interface supply mechanism 17 . The filling and sealing device includes a filling and sealing mechanism 12 , a sealing mechanism 13 , a cooling mechanism 14 , a bag output mechanism 15 , and a second circular transfer assembly 16 . A plurality of clamps are evenly distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com