Asphalt material for road as well as preparation method and preparation device of asphalt material

An asphalt material and asphalt technology, applied in the field of modified asphalt material and its preparation method and preparation device, can solve the problems of poor water damage resistance and high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

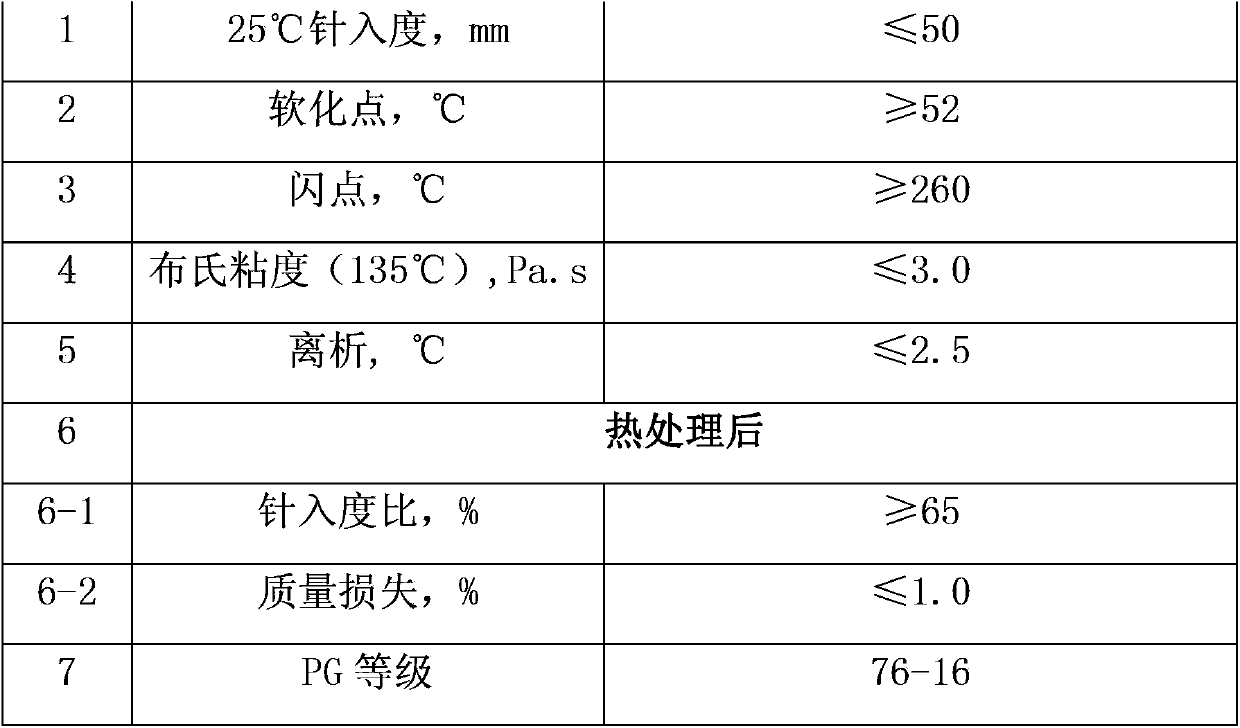

[0028] An asphalt material for roads, the composition of which consists of 1-20% of natural rock asphalt, and the rest is matrix asphalt. Its base asphalt is 70# base asphalt or 90# base asphalt.

[0029] The preparation method of above-mentioned asphalt material for road, comprises the steps:

[0030] (1) Weigh the matrix asphalt and natural rock asphalt according to their weight percentage, and set aside;

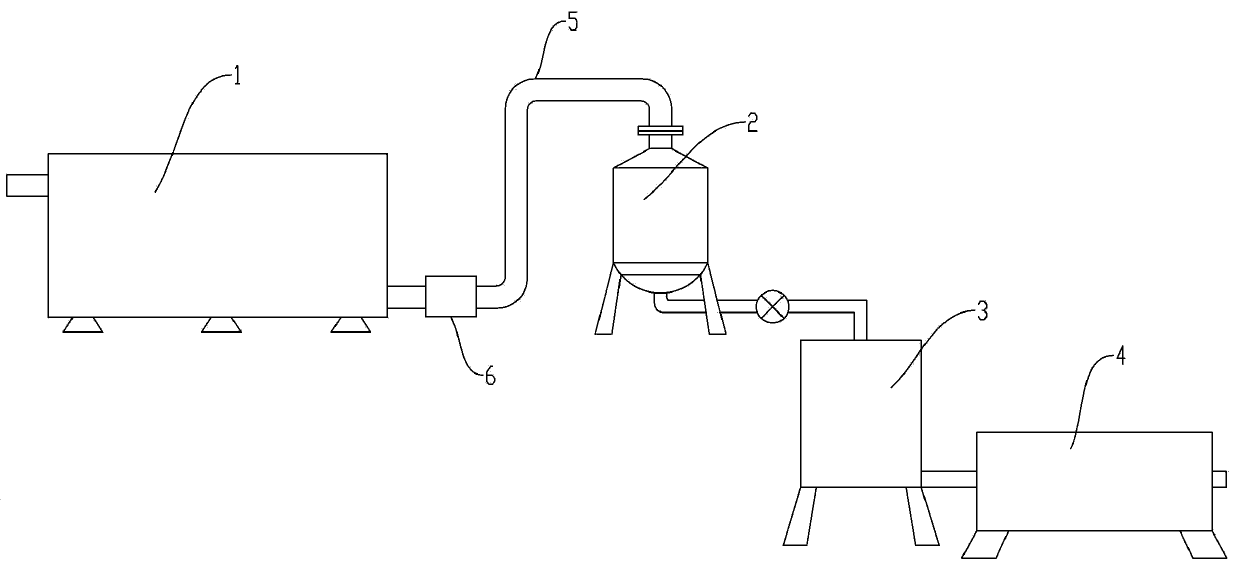

[0031] (2) Put the base asphalt of the above weight into the heating tank, and then heat up the required equipment, the temperature of the heating tank storing the base asphalt is raised to 165°C, and the temperature of the asphalt conveying pipeline, mixing tank, metering tank, and ball mill is raised to 165°C , and then drive the base asphalt in the heating tank into the mixing tank through a delivery pump, and keep the temperature of the mixing tank between 160 and 165°C; 164°C, 163°C, 162°C, and 161°C are all available Preferably 165°C;

[0032] (3) Add the natural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com