Method for extracting brown pigment of chestnut shells by using ultrasonic waves

A chestnut shell, ultrasonic technology, applied in chemical instruments and methods, azo dyes, organic dyes and other directions, can solve the problems of low quality, many impurities, waste, etc., to improve the number of recycling, the extraction process is simple, and the quality excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

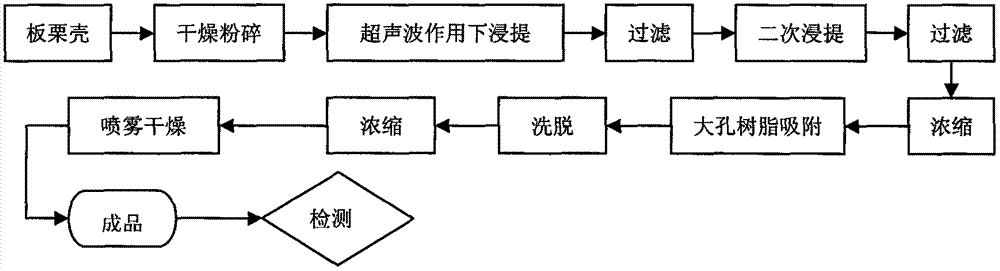

Image

Examples

Embodiment 1

[0026] The chestnut shells are dried in an oven until the moisture content is 10%, and then pulverized, and the pulverized chestnut shells are passed through a 60-mesh sieve, and the flocs in the shells are removed. Mix the processed chestnut shell powder with ethanol-sodium hydroxide extractant in a ratio of 1:15 (w / v), and perform the first leaching at a temperature of 70°C and an ultrasonic power of 500w. The time is 2 hours. After standing and filtering, save the first extract, and mix the filter residue with the ethanol-sodium hydroxide extracting agent in a ratio of 1:10 (w / v). Carry out the leaching for the second time under, the leaching time is 1 hour. After static filtration, the two extracts were combined, filtered through a 200-mesh filter cloth, and the filtrate was concentrated under reduced pressure at 40°C and 0.1 MPa. Pump the concentrated pigment solution into the DA-201 macroporous resin column at a flow rate of 3.6ml / min, and elute the chestnut shell brow...

Embodiment 2

[0028] The chestnut shells are dried in an oven until the water content is 8%, and then pulverized, and the pulverized chestnut shells are passed through a 50-mesh sieve, and the flocs in the shells are removed. Mix the processed chestnut shell powder with ethanol-sodium hydroxide extractant in a ratio of 1:20 (w / v), and perform the first leaching at a temperature of 60°C and an ultrasonic power of 400w. The time is 1.5 hours. After standing and filtering, save the first extract, and mix the filter residue with the ethanol-sodium hydroxide extracting agent in a ratio of 1:10 (w / v). Carry out the leaching for the second time under, the leaching time is 1 hour. After static filtration, the two extracts were combined, filtered through a 200-mesh filter cloth, and the filtrate was concentrated under reduced pressure at 40°C and 0.1 MPa. Pump the concentrated pigment solution into the DA-201 macroporous resin column at a flow rate of 3.6ml / min, and elute the chestnut shell brown ...

Embodiment 3

[0030] The chestnut shells are dried in an oven until the moisture content is 10%, and then pulverized, and the pulverized chestnut shells are passed through a 60-mesh sieve, and the flocs in the shells are removed. Mix the processed chestnut shell powder with ethanol-sodium hydroxide extractant in a ratio of 1:20 (w / v), and perform the first leaching at a temperature of 60°C and an ultrasonic power of 500w. The time is 2 hours. After standing and filtering, save the first extract, and mix the filter residue and ethanol-sodium hydroxide extractant in a ratio of 1:10 (w / v) evenly. Carry out the leaching for the second time under, the leaching time is 1 hour. After static filtration, the two extracts were combined, filtered through a 200-mesh filter cloth, and the filtrate was concentrated under reduced pressure at 40°C and 0.1 MPa. Pump the concentrated pigment solution into the DA-201 macroporous resin column at a flow rate of 3.6ml / min, and elute the chestnut shell brown pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com