Construction of manhole cover template facility of roads

A technology of road construction and formwork, applied in construction, artificial islands, water conservancy projects, etc., can solve the problems of heavy labor intensity, manpower, raw materials, time, economic waste, etc., to save raw materials, save construction time, and facilitate road paving The effect of mechanical construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

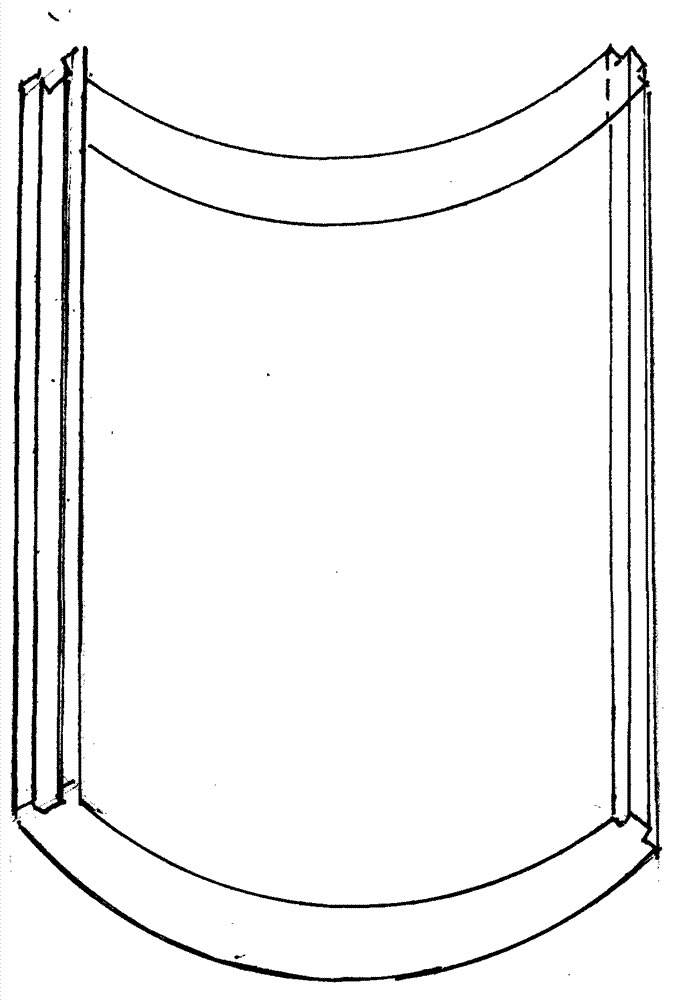

[0014] figure 1 The construction and construction of the highway solid well formwork facilities shown, the three-dimensional view of the middle part of the formwork, this picture is the male and female handover diagram of the upper and lower joints of the solid well part formwork, it is a combination of upper and lower widths, and the formwork can be spliced according to the thickness But the middle must use soon image 3 For splicing.

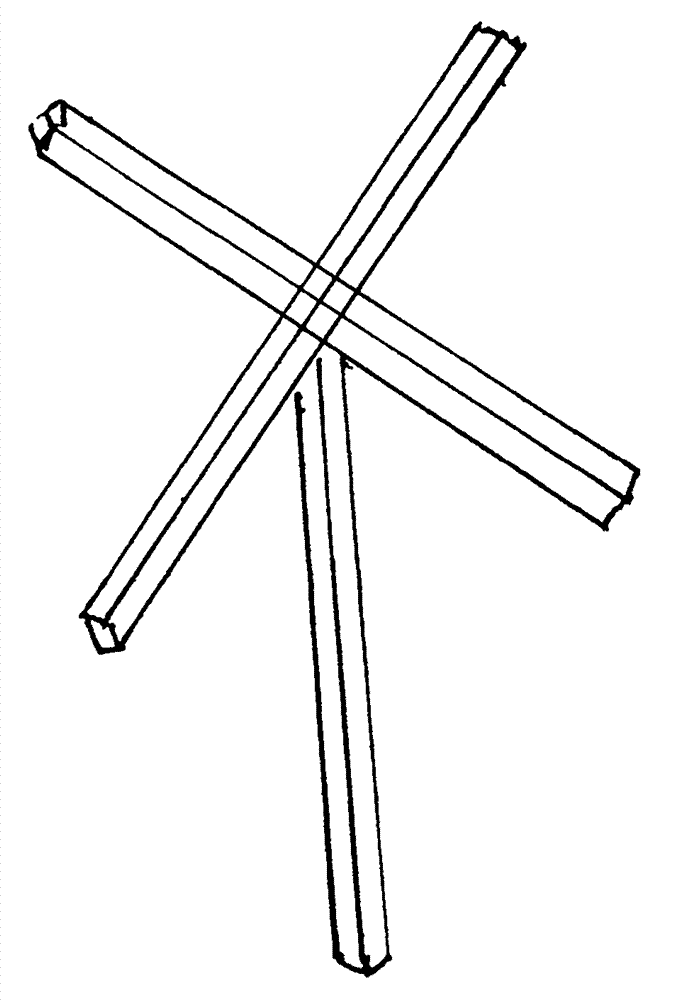

[0015] figure 2 The three-dimensional view of the construction of the formwork facilities of the highway solidification well and the formwork support in the construction solidification well are shown. The high and low support is a temporary support facility. A column support is designed for a well. Plane formwork support is implemented on the column, and the temporary solid cover is covered on the support frame. The height of the formwork is calculated according to the height of the formwork, and the inner support part of the temporary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com