Two-degree-of-freedom hinged joint with single-direction return function

A hinged joint and degree of freedom technology, applied in the direction of pivot connection, etc., can solve the problems of uneven force on the shaft installation hole, lack of spring automatic reset function, and increased difficulty in fixing the wire rope and joint, so as to improve the bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

[0015] Basic principle of the present invention:

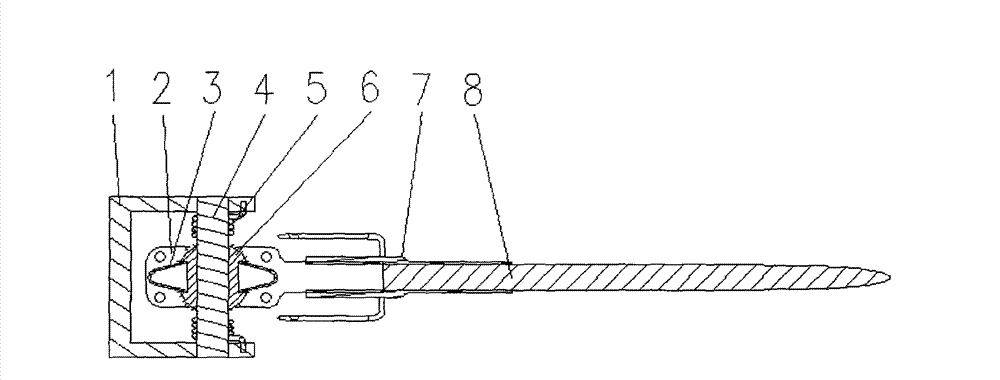

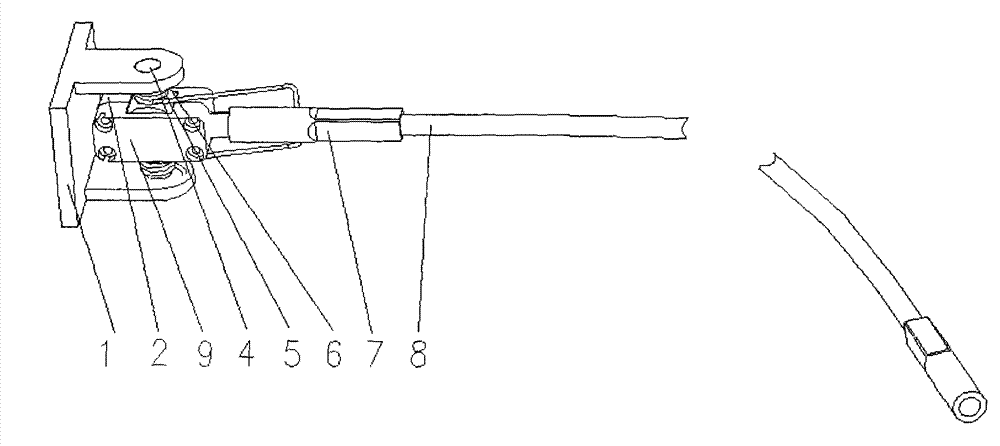

[0016] 1. If figure 1 As shown, when the steel wire rope rotates in a direction perpendicular to the paper surface, the slotted cylinder 6 rotates around the rotation axis 4, and there is no relative movement between the slotted cylinder 6 and the shell 2, and the part of the metal sleeve 7 installed on the elongated section of the shell is forced to twist The spring 5 twists to generate torsion. When the force driving the rotation of the steel wire rope 8 disappears, the torsion force of the torsion spring 5 forces the shell 2 to drive the slotted cylinder 6 to rotate toward the initial position to realize reset;

[0017] 2. If figure 1 As shown, when the wire rope rotates parallel to the paper surface, the slotted cylinder 6 and the rotating shaft 4 are relatively stationary, and the shell 2 and the slotted cylinder 6 rotate relative to each other. Since the contact here is a cylindri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com