Water and refrigerant heat exchanger with evaporative heat exchange and condensing heat exchange functions

A technology of condensation heat exchange and evaporation heat exchange, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc. Poor effect and other problems, to achieve the effect of solving the low utilization rate of heat exchange area, high utilization rate of cylinder space, and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

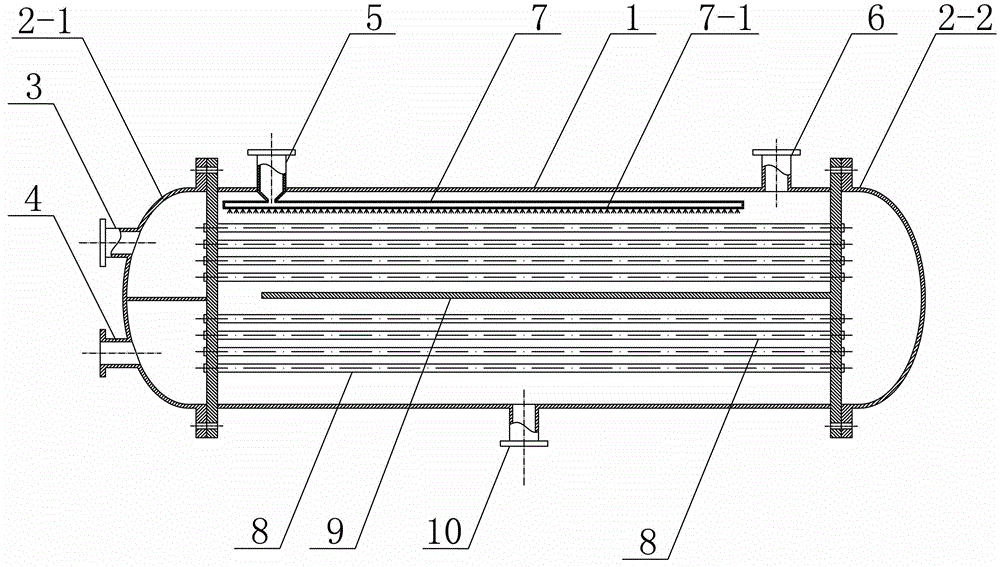

[0008] Specific implementation mode one: combine figure 1 Describe this embodiment, a water-refrigerant heat exchanger with both evaporation heat exchange and condensation heat exchange functions in this embodiment includes a cylinder 1, a first tube cavity 2-1, a second tube cavity 2- 2 and a plurality of heat exchange tubes 8, the first tube cavity body 2-1 and the second tube cavity body 2-2 are fixedly connected to the left and right ends of the cylinder body 1 respectively, and the medium water inlet 3 and the medium water outlet 4 are arranged at the On the first tube cavity 2-1 or the second tube cavity 2-2, the refrigerant inlet 5 and the first gaseous refrigerant nozzle 6 are arranged on the upper end of the cylinder 1, and the liquid refrigerant nozzle 10 is arranged on the cylinder 1 At the lower end of the lower end, a plurality of heat exchange tubes 8 are arranged in parallel in the cylinder 1 from top to bottom, and communicate with the first tube cavity 2-1 and...

specific Embodiment approach 2

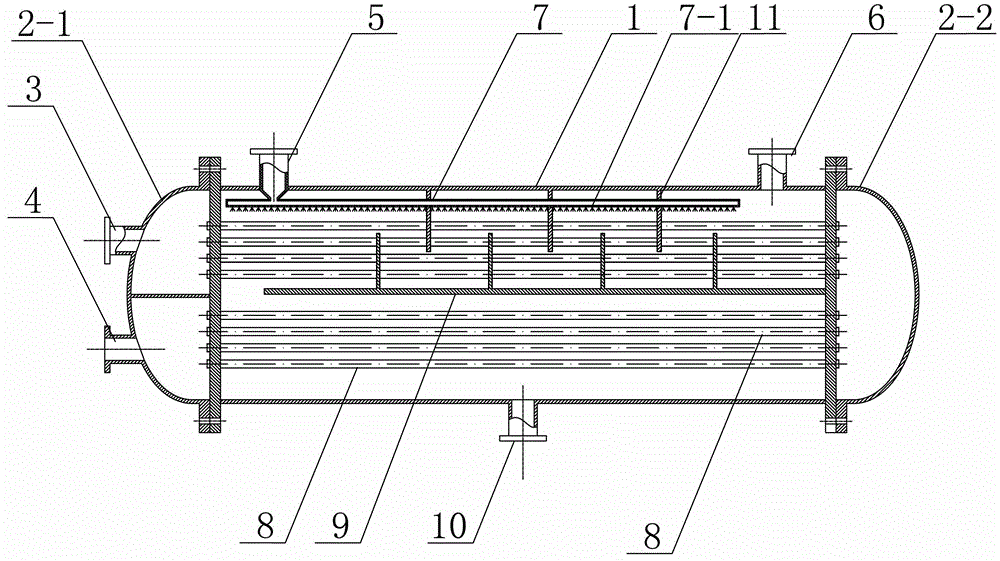

[0015] Specific implementation mode two: combination figure 2 To illustrate this embodiment, the water-refrigerant heat exchanger of this embodiment also includes a plurality of baffles 11, and the plurality of baffles 11 are respectively fixed on the upper end of the inner wall of the cylinder 1 and the first partition 9, and more The baffles 11 are interlaced with each other. With such arrangement, when the present invention is used as a condenser, the flow rate and disturbance of the refrigerant gas entering through the first gas refrigerant nozzle 6 are effectively improved, and the effect of heat exchange is enhanced. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

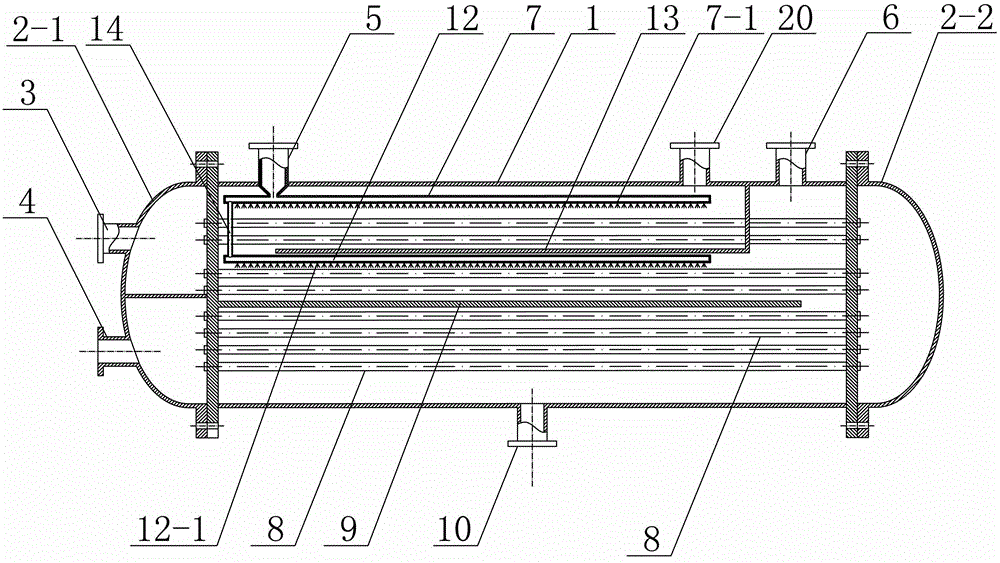

[0016] Specific implementation mode three: combination image 3 To illustrate this embodiment, the water and refrigerant heat exchanger of this embodiment also includes a second falling film device 12, a second separator 13 and a tube body 14, and the second falling film device 12 is arranged on the first falling film device 12 through the tube body 14. Below the film device 7, and the second falling film device 12 is located in the upper chamber, the lower end of the second falling film device 12 has a plurality of second through holes 12-1, and the second partition 13 is arranged on the first falling film device Between 7 and the second falling film device 12, a second gaseous refrigerant nozzle 20 is opened on the cylinder 1 above the second separator 13. Such setting can effectively increase the amount of falling film evaporation refrigerant and improve the effect of heat exchange. At the same time, during the condensation process, the flow channel size of the refrigerant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com