Mine roadway advancing and undermining method and main blasting parameters

A main parameter, mine leveling technology, applied in the field of mine mining technology, can solve the problems of increasing ore-rock intercalation, no free surface, difficult slotting, etc., to shorten the construction period, improve the utilization rate of blast holes, and save the consumption of explosives. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

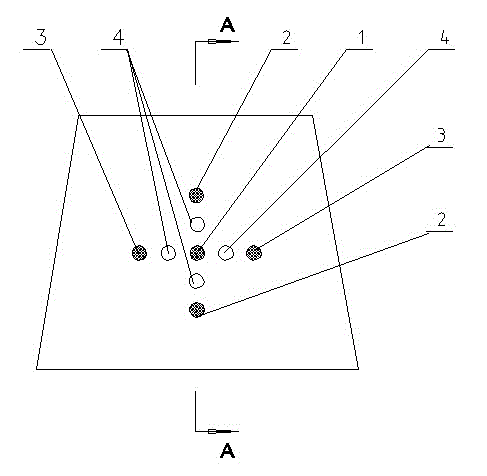

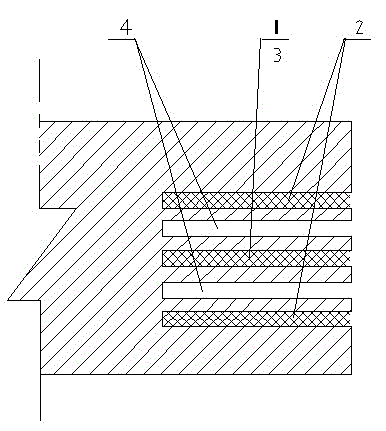

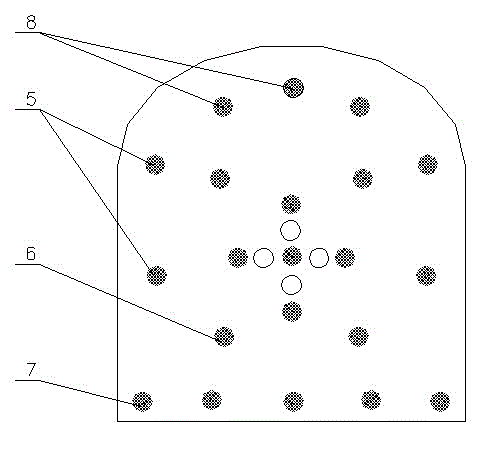

[0041] Example 1 Such as Figure 1-4 Shown: The tunneling and cutting method and the main parameters of the blasting of the medium-hard ore rock in the Kumeishan Tungsten Mine in Jiangxi Province. The blastholes are arranged in the way of double-ear cracking and cutting. The nine cutting blastholes are perpendicular to the vertical working surface. Arranged along the cross 20cm below the center of the working surface, where the central blasthole 1 and the four end blastholes 2 of the cross are charge holes, and the center blasthole 1 and the four end blastholes 2 are empty holes 3, The hole spacing is 10cm.

[0042] The main parameters of tunneling and blasting include blasthole diameter, blasthole depth, blasthole spacing, blasthole number and unit explosive consumption;

[0043] [1] Blasting hole diameter: The blasting hole diameter affects the rock drilling productivity, the number of holes, the unit explosive consumption and the smoothness of the roadway wall. The incre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com