Visual measuring device and visual measuring method for coordinates of surface of target based on round light spot marks

A technology of visual measurement and measurement method, which is applied in the direction of measuring device, photogrammetry/video metrology, optical device, etc., can solve the problems of large manual participation, change of measured surface characteristics, low efficiency, etc., and achieve simple structure, The effect of improving work efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

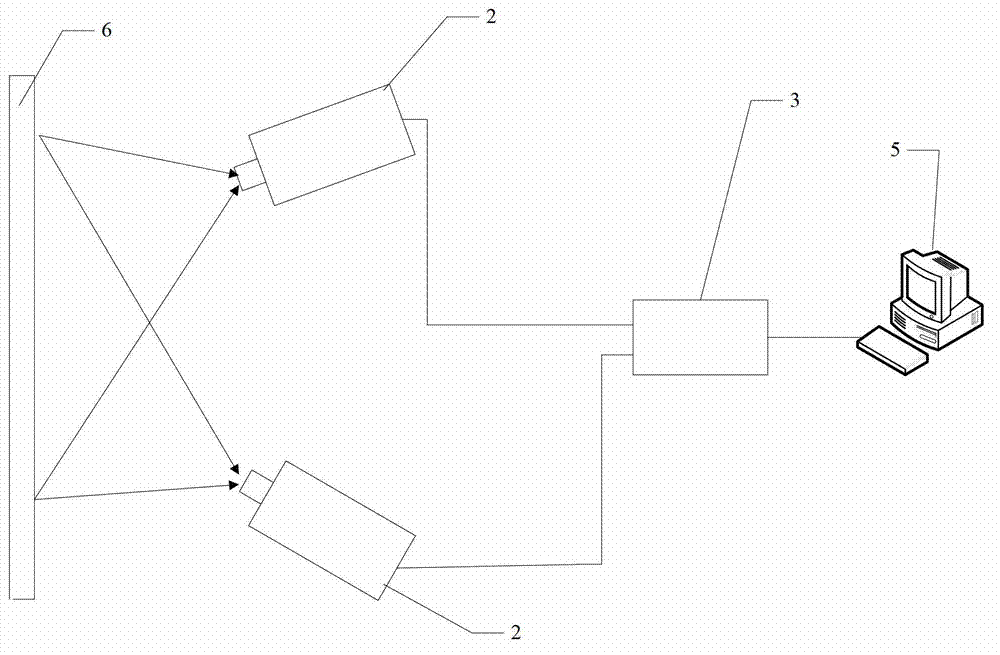

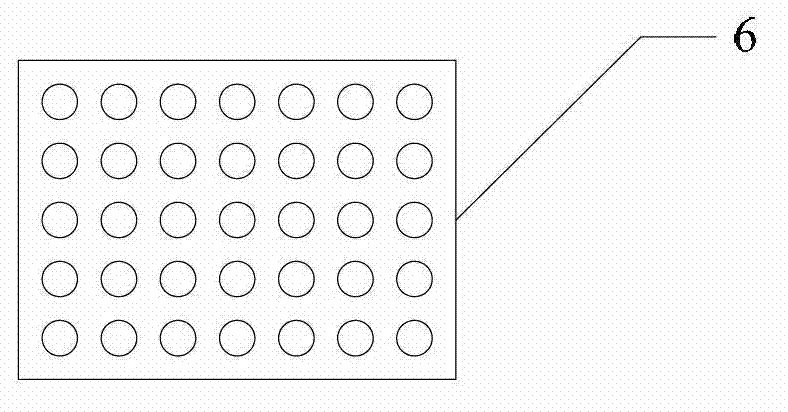

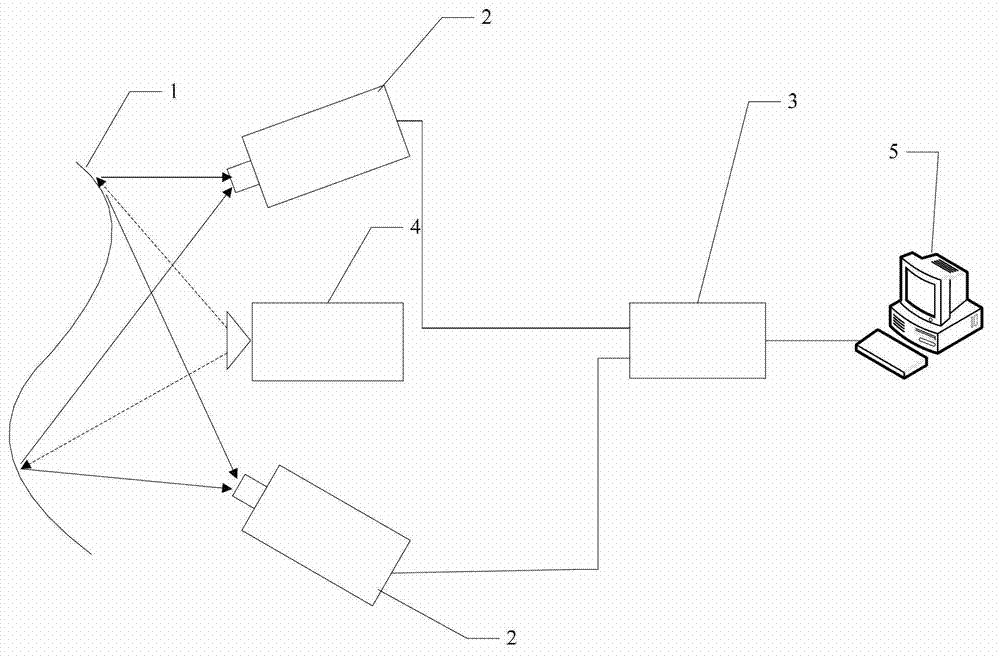

[0029] Specific implementation mode 1. Combination figure 1 and figure 2 Describe this specific embodiment, the visual measurement device based on the target surface coordinates of circular spot mark, it is made up of two visual image sensors 2, visual image acquisition device 3, projector 4 and circular spot array target 6;

[0030] The image projection lens of the projector 4 faces the surface 1 of the measured object;

[0031] The image acquisition lenses of the two visual image sensors 2 are all towards the circular spot array target 6 or the surface 1 of the measured object, and the image data output ends of each of the visual image sensors 2 are respectively connected to the two images of the visual image acquisition device 3 The data input end is connected, and the image data output end of the visual image acquisition device 3 is connected with the image data input end of the remote control center 5 .

[0032] Said two visual image sensors 3 and projector 4 are arran...

specific Embodiment approach 2

[0037] Specific embodiment two, this specific embodiment is the measurement method of the visual measuring device based on the target surface coordinate of circular spot mark according to specific embodiment one:

[0038] The measuring method of the visual measuring device based on the coordinates of the target surface marked by the circular light spot, its steps are as follows:

[0039] Step 1: Calibration stage: the image acquisition lenses of the two visual image sensors 2 are all directed towards the circular spot array target 6, and the distance from the image acquisition lens of the visual image sensor 2 to the circular spot array target 6 is less than 1 meter;

[0040] Step 2: adjust the positions of the two visual image sensors 2 respectively, so that the image acquisition lenses of the two visual image sensors 2 are aligned with the same measurement area on the circular spot array target 6, and the circular spot array target 6 is evenly and clearly distributed on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com