Equal thickness interference method based centering error measuring device

A measuring device and center error technology, applied in the field of optical measurement, can solve problems such as inability to measure lenses, and achieve high precision, stable and reliable methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

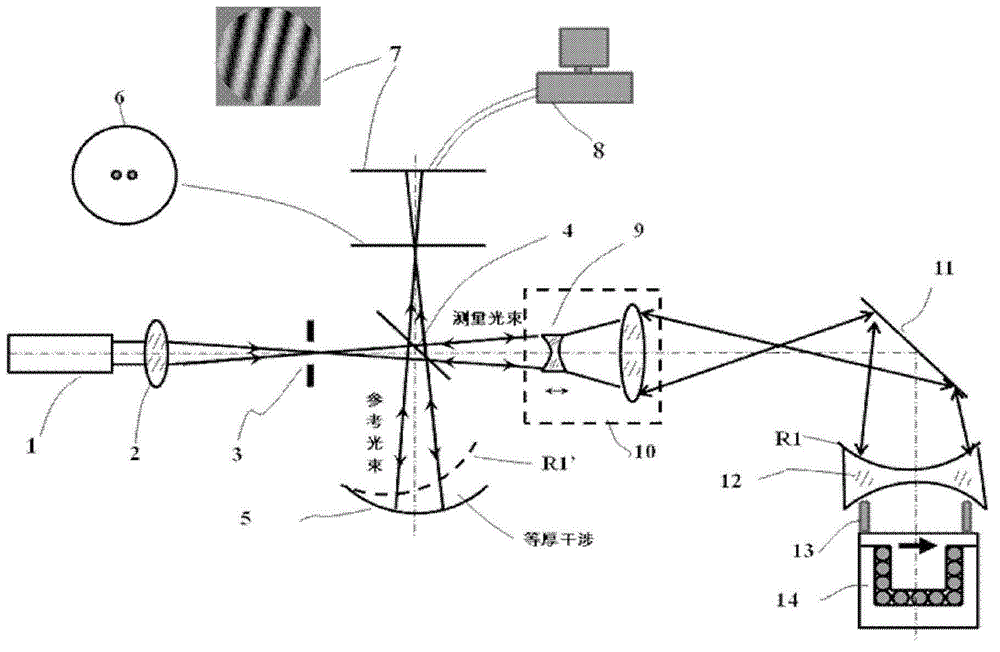

[0024] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

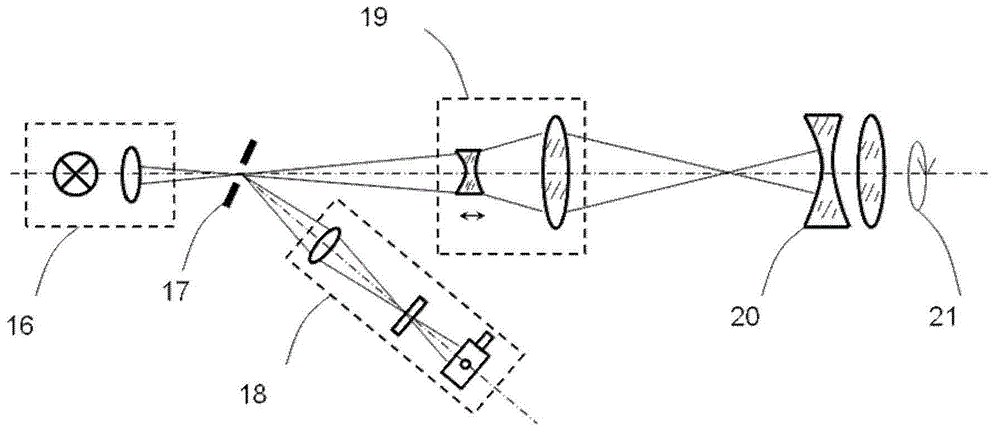

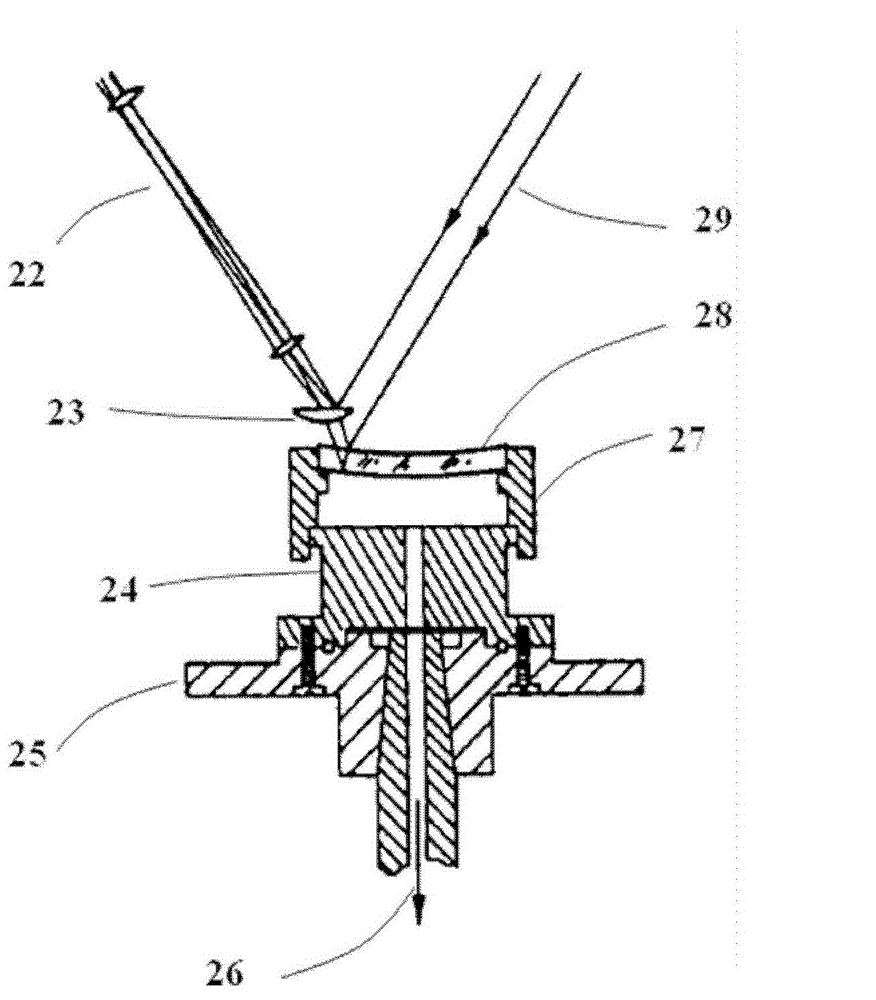

[0025] like image 3 The measuring device of the center error based on the equal thickness interferometry of the present invention is shown, including a laser 1, a converging mirror 2, a star point plate 3, a beam splitter 4, a reference mirror 5, a receiving screen 6, a CCD detector 7, a calculation group 8, Focusing group 10, refracting mirror 11, lens under test 12, connecting tool 13 and precision rotating shaft 14, wherein:

[0026] On the optical axis of the laser 1, place the converging mirror 2, the star point plate 3 and the beam splitter 4 in sequence, and the star point plate 3 is located at the focal point of the converging mirror 2; The filtering of the plate 3 forms a filtered beam, which reaches the beam splitter 4 and is split into a reference beam and a measurement beam.

[0027] The reference mirror 5, the receiving screen 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com