In-situ temperature testing device and method

A technology of in-situ temperature and testing devices, applied in the direction of measuring devices, thermometers, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

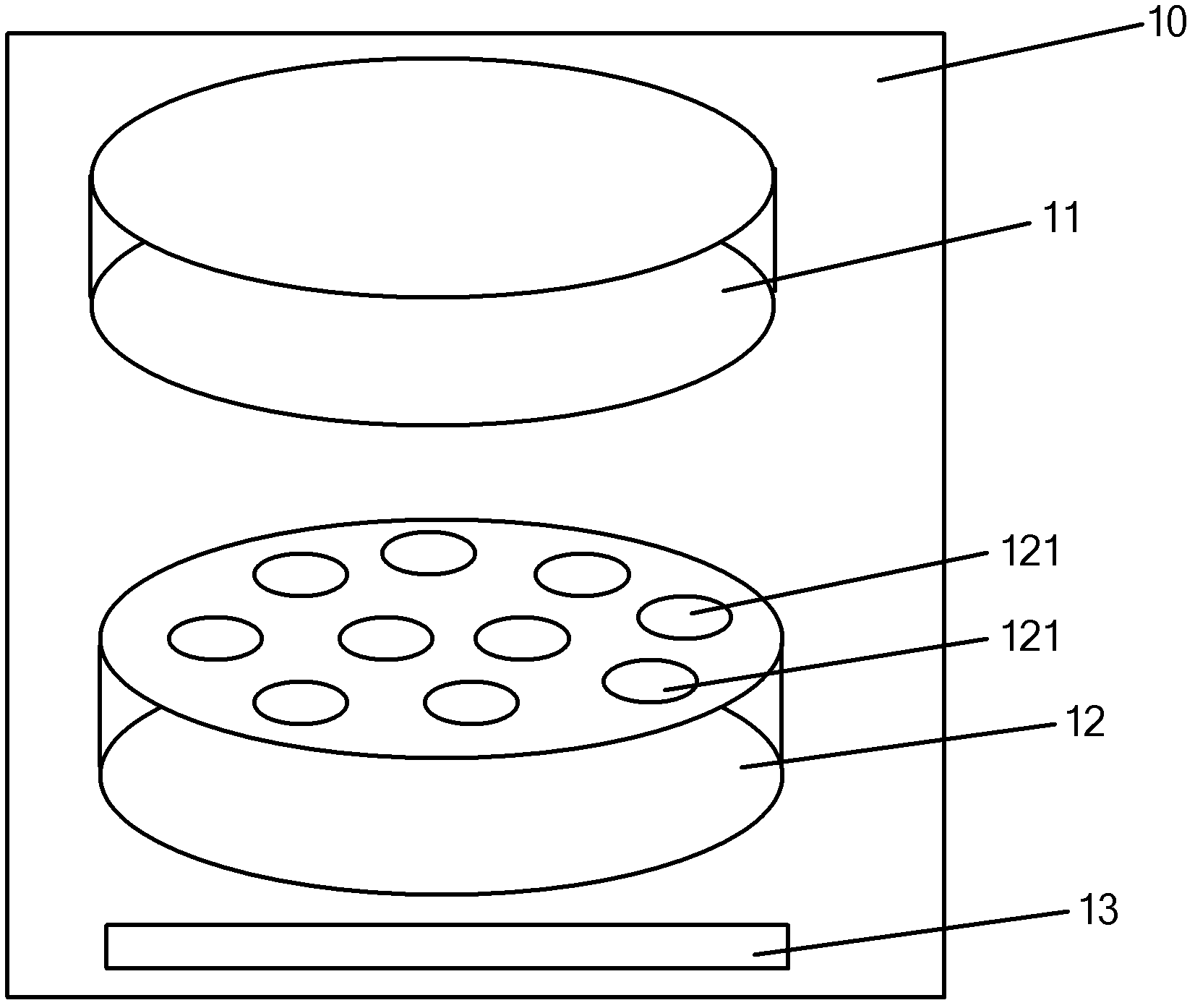

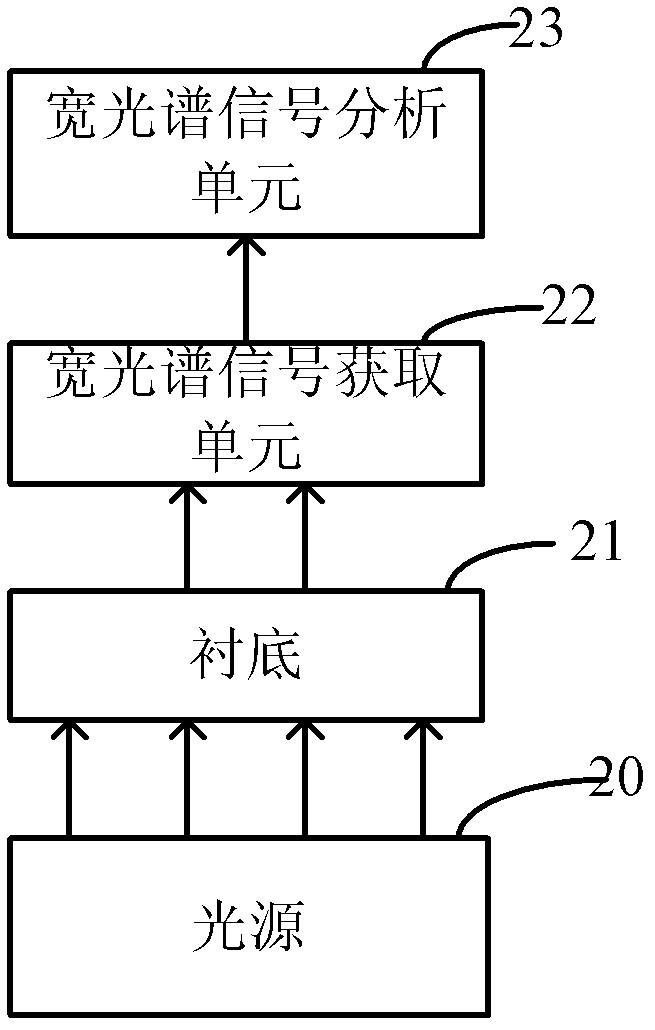

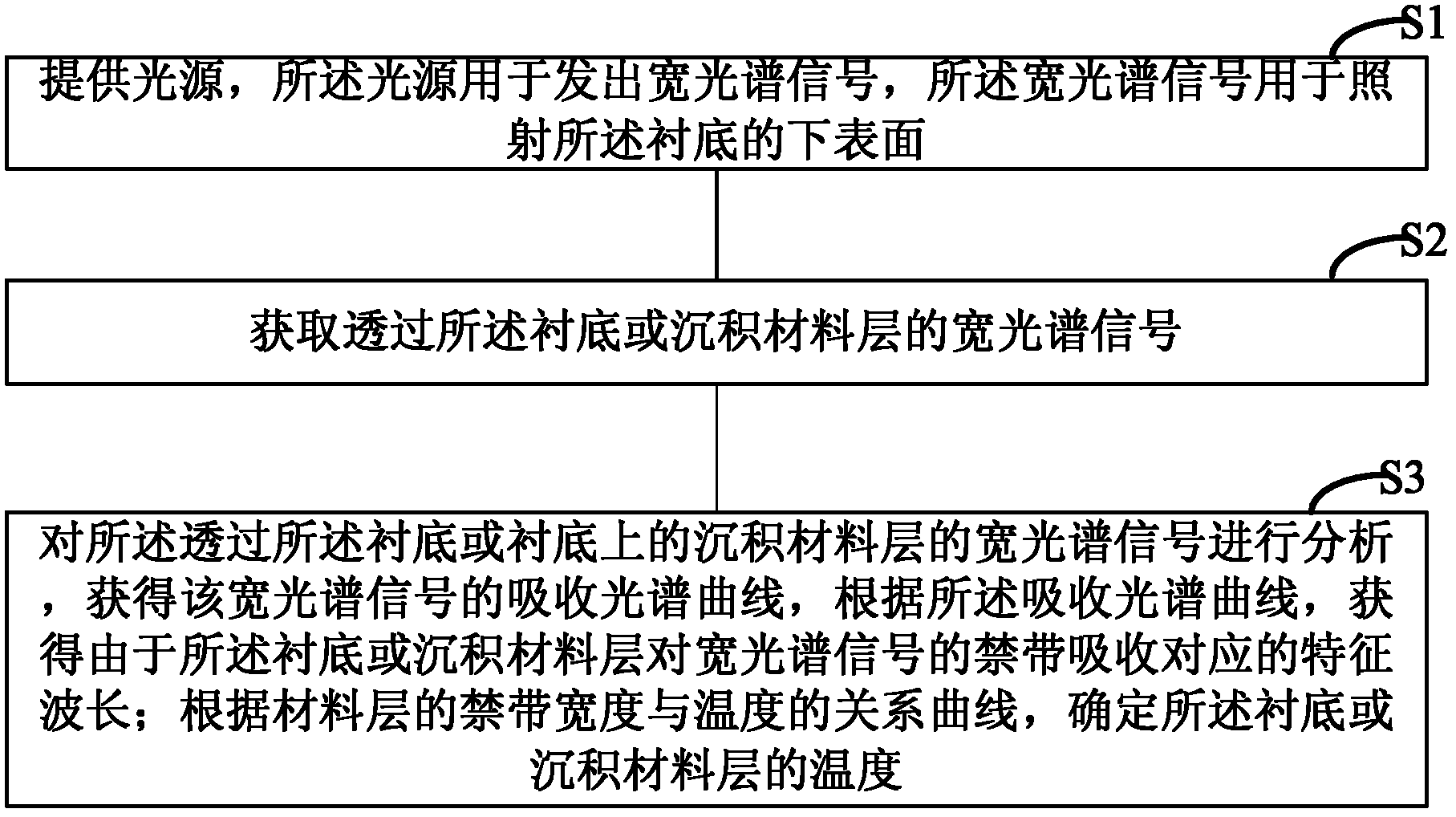

[0076] The vapor deposition process has a higher temperature for the substrate or the deposition material layer on the substrate. The temperature of the substrate or the deposition material layer on the substrate needs to meet the requirements of the vapor deposition process and reach the temperature required for the chemical reaction of the source material. Moreover, the temperature of the substrate or the deposited material layer on the substrate also needs to meet a certain degree of uniformity to ensure that the thickness of the finally formed deposited material layer is uniform, and to prevent the substrate from warping and deformation due to uneven thermal stress. Therefore, when the vapor deposition process is carried out in the process chamber of the MOCVD equipment, no matter the deposition material layer has not been formed on the substrate at the initial stage or a part of the deposition material layer has been deposited on the substrate during the vapor deposition pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com