Online electric abrasion detecting method and system of vacuum circuit breaker

A vacuum circuit breaker and detection method technology, applied in the direction of circuit breaker testing, etc., can solve the problems of lack of systematic theoretical basis, low monitoring precision and accuracy of electric wear online detection and diagnosis system, and no theoretical and calculation basis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

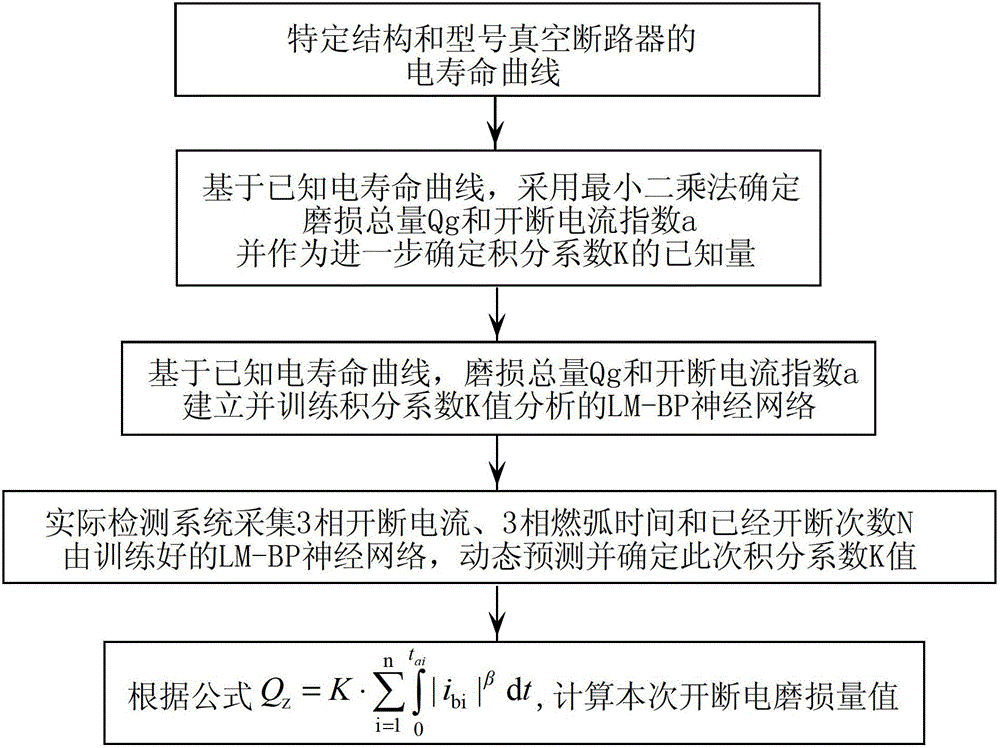

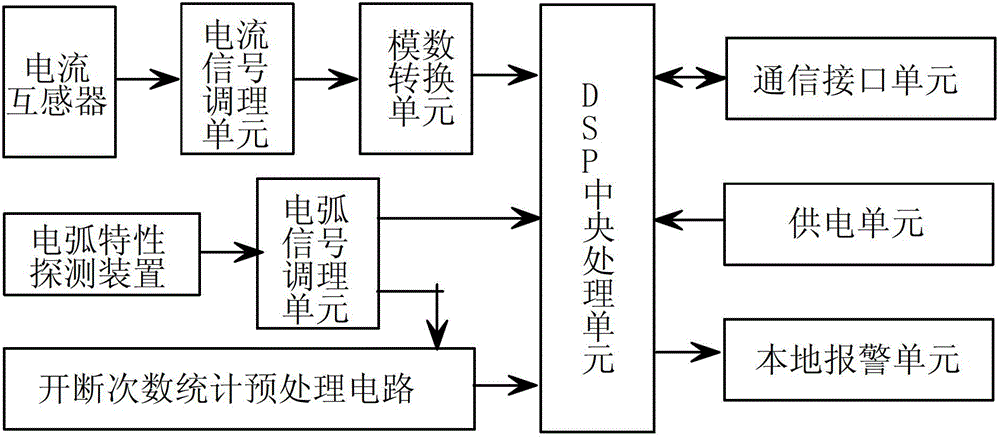

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with specific example, the present invention is described in detail:

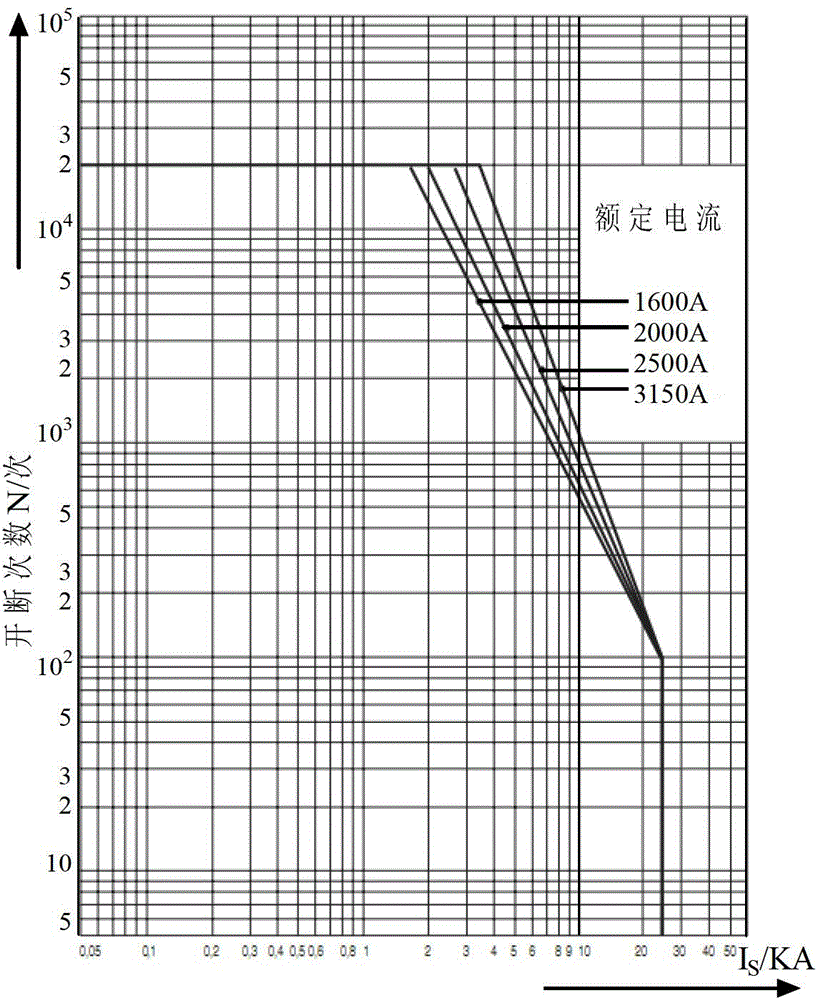

[0046] The main feature of the vacuum circuit breaker is that it can safely and repeatedly break the short-circuit current without the need to overhaul its breaking element (interrupter), or replace it after reaching a certain level, that is, the breaking capacity without maintenance. The vacuum interrupter is a non-removable maintenance component, so the vacuum circuit breaker and assembly cabinet equipped with a vacuum interrupter need an electrical life test; domestic and foreign manufacturers perform a series of experiments to determine the electrical life of their products to enhance their competitiveness . image 3 Shown is the typical electrical life characteristic curve of ABB’s VD4 vacuum circuit breaker, indicating that the vacuum circuit breaker operates at different rated currents I n Below, the relationship between breaking current and breaking times:

[0047] N i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com