Control method for neutral-point voltage of bus of 10kW three-phase grid-connected inverter

A control method and a technology of a three-level inverter, which are applied in directions such as converting irreversible DC power input into AC power output, can solve the problems of uneven bus voltage division, increased power consumption, and low control accuracy, and achieve The effect of high power output quality requirements, reduced power loss, and simple control steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Embodiments of the inventive method are as follows:

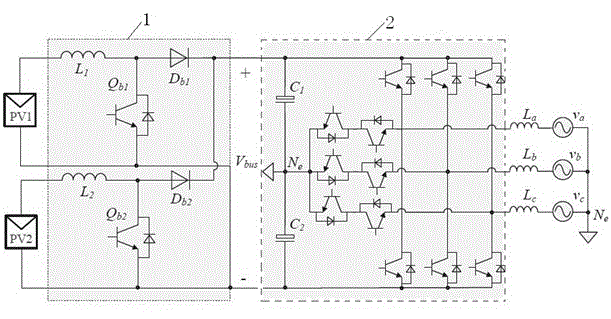

[0009] The method is based on figure 1 The main circuit of the 10kW inverter is shown. The front stage of this circuit adopts two-way Boost converter 1, L 1 and L 2 is the boost inductor, Q b1 and Q b2 is the main switching tube, D b1 and D b2 It is a freewheeling diode; the latter stage adopts a T-type three-level inverter 2, C 1 and C 2 is the bus voltage divider capacitor, L a , L b and L c is the inverter output filter inductance, v a , v b and v c is the three-phase voltage. In this embodiment, the input voltage of the photovoltaic panel is 250V-800V, the output voltage of the Boost converter is 800V, the output voltage of the inverter is 220V AC, and the bus voltage dividing capacitor C 1 and C 2 Both are 560μF. During the control process, the bus voltage dividing capacitor C is alternately used at intervals of 0.2 seconds 1 and C 2 The voltage at both ends is sampled to obtain the sampled va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com