Protective energy-saving pressure cooker

A pressure cooker and pot cover technology, applied in the field of pressure cooker, can solve the problems of large exposed area of metal surface, easy to be scalded or scalded, and much heat lost, so as to speed up the cooking process and reduce the chance of scalding or scalding. Good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

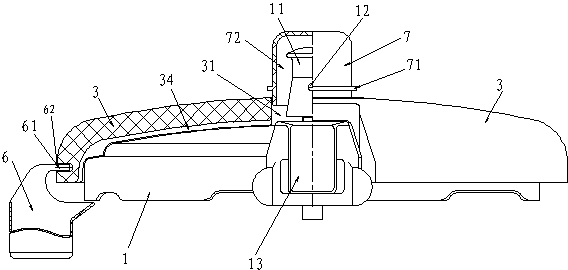

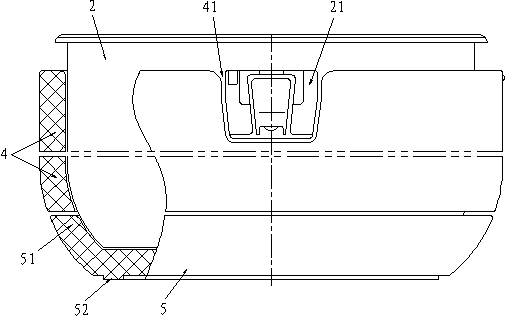

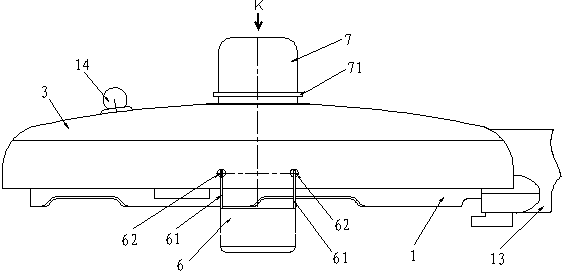

[0021] The protective energy-saving pressure cooker of the embodiment of the present invention (for the structure see Figure 1-Figure 8 ), including a pot body 2 and a matching pot cover 1, its structural feature is that: the pot cover 1 is also provided with a heat shield 3 covering its surface;

[0022] The above-mentioned heat shield 3 is an integral structure made of foamed plastic material; the heat shield 3 is provided with a valve position hole 31 for avoiding the bonnet 11 of the pressure limiting valve, and the circumference of the valve position hole 31 and the bonnet 11 There is a suitable exhaust space between the sides, so that the gas ejected from the valve cap 11 can be discharged from the space; the heat shield 3 is provided with a handle groove 32 for avoiding the cover handle 13 .

[0023] The above-mentioned heat shield 3 is provided with a safety hole 33 for avoiding the safety valve 14, so that the function of the safety valve 14 will not be affected.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com