Multi-axis rotating production equipment used for part assembling of reduction gear

A production equipment and reducer technology, applied in metal processing equipment, assembly machines, metal processing, etc., can solve the problems of workpiece damage and industrial accidents, assembly quality cannot be guaranteed, and equipment capital investment is high, so as to increase the service life and save equipment Space, convenient and simple hoisting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

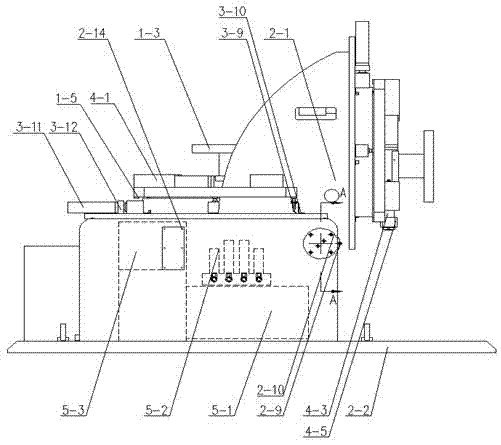

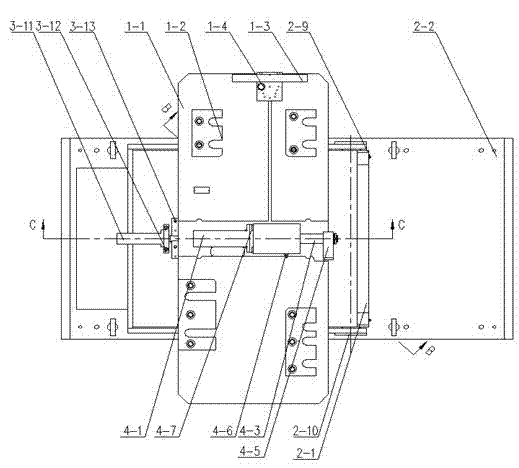

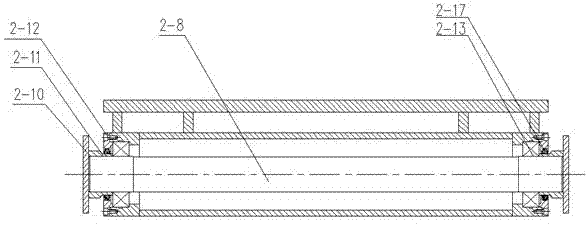

[0031] Such as Figure 1-Figure 6 As shown, a multi-axis rotary production equipment for the assembly of reducer parts is composed of a workbench, a hydraulic turning mechanism, a hydraulic rotating mechanism, a hydraulic unpin assembly and a hydraulic station connection.

[0032] The workbench is connected with the slewing bearing in the hydraulic rotating mechanism through bolt connection and placed on the upper surface of the slewing bearing; the pin hole positioning and bolt connection of the hydraulic turning mechanism will turn the turning table and the slewing bearing in the hydraulic turning mechanism The supports are connected together and placed on the lower surface of the hydraulic rotating mechanism, and the hydraulic turning mechanism connects the turning ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com