Manufacturing method for plastic plate internally provided with patterns

A manufacturing method and plastic technology, applied in chemical instruments and methods, printing and laminating devices for producing special types of printed matter, etc., can solve problems such as poor pattern definition, poor operability, and printing quality guarantee, and achieve High production efficiency, not easy to change color, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

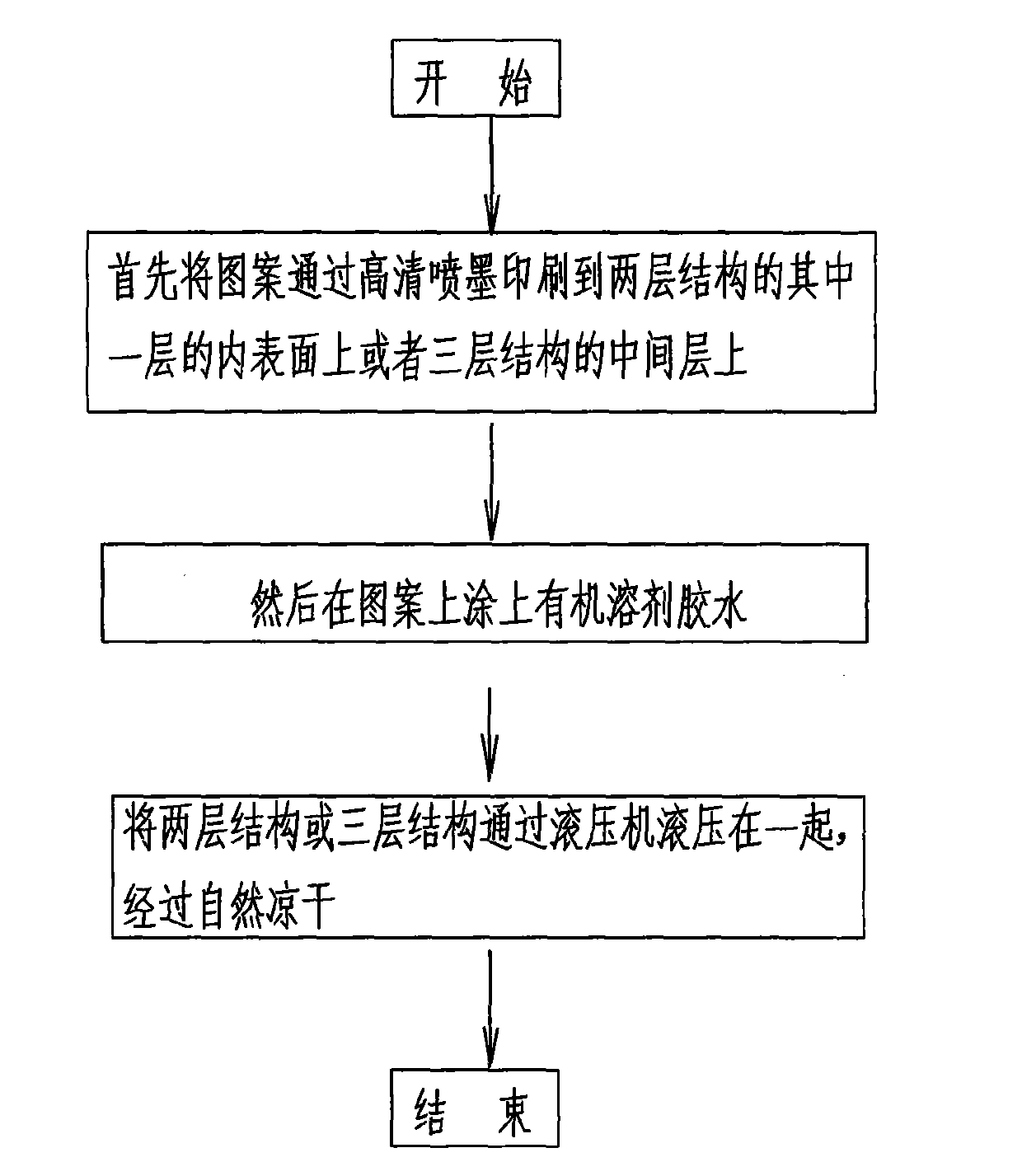

[0014] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

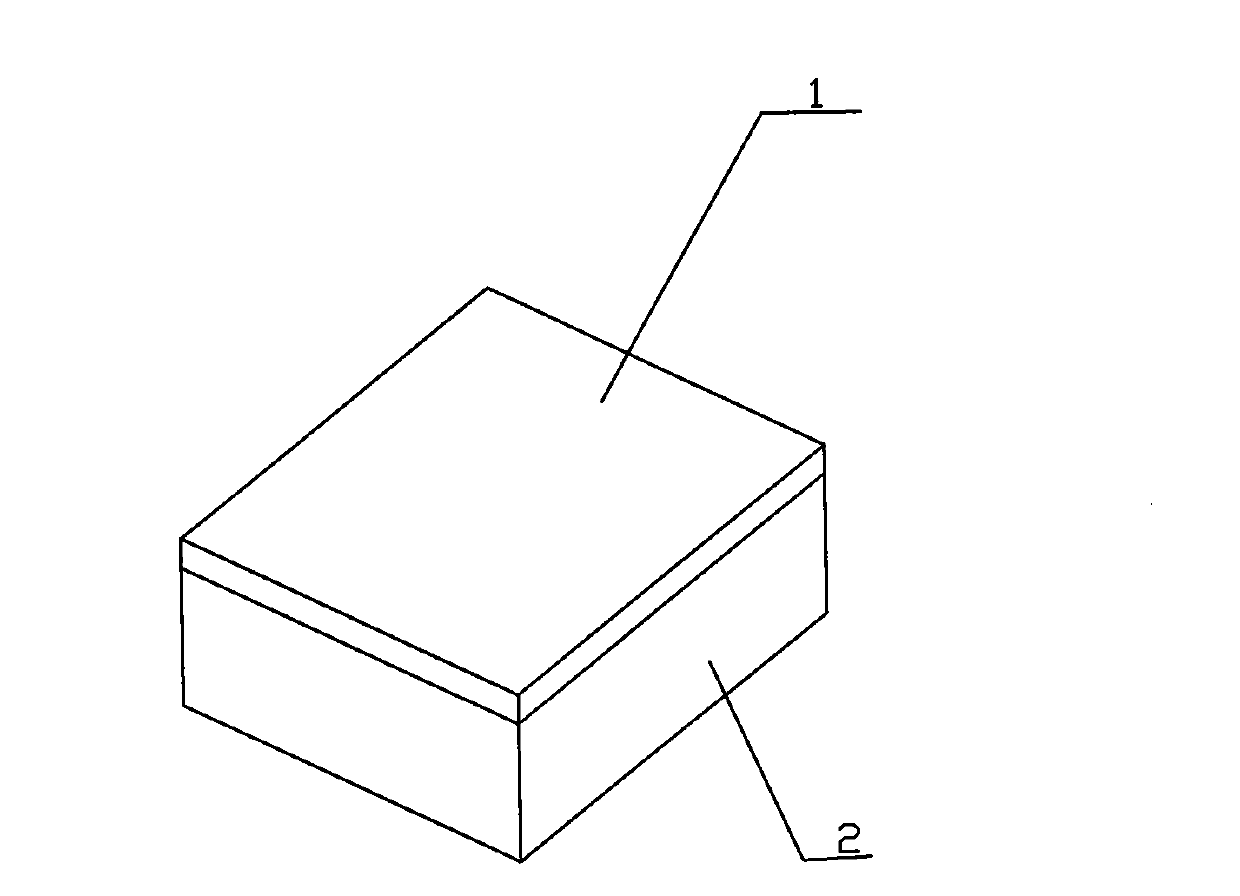

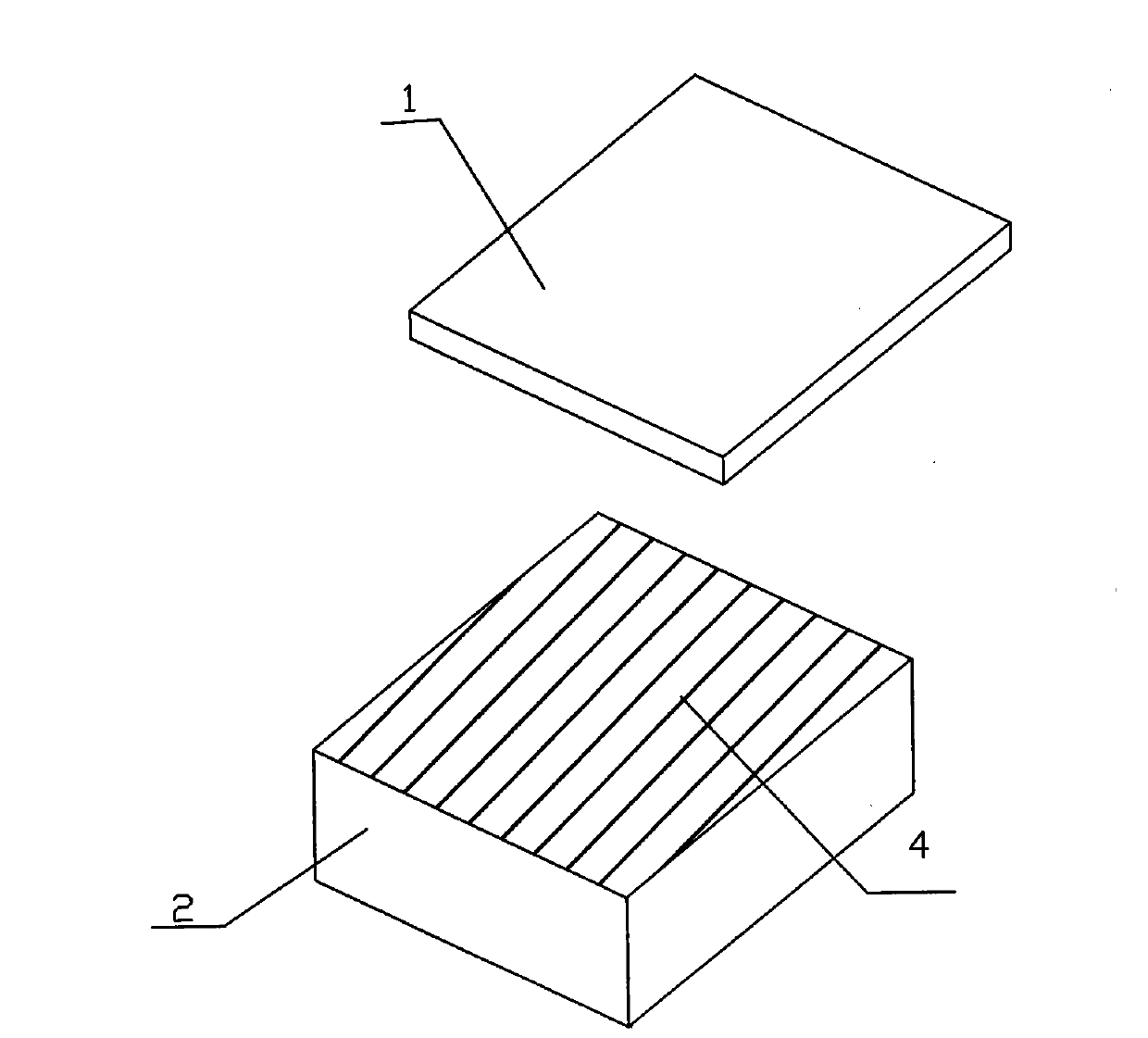

[0015] The patterned plastic sheet has a two-layer structure or a three-layer structure. The two-layer plastic sheet includes: a panel 1 and a bottom plate 2, both of which are made of cellulose diacetate transparent board, and the pattern 4 is printed on the front panel 1 or the bottom plate 2. on the inner surface (such as Figure 2a with Figure 2b shown); the plastic sheet of the three-layer structure includes: a panel 1 and a base plate 2 and an intermediate layer 3 between the panel 1 and the base plate 2, the pattern 4 is printed on the intermediate layer 3, and the intermediate layer 3 is a solid white negative film or Transparent sheet, when the middle layer 3 is a solid white negative film, you can also stick a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com