Push shovel and garbage truck provided therewith

A technology for a garbage truck and a carriage is applied in the field of a push shovel and a garbage truck with the push shovel. The effect of reducing operating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

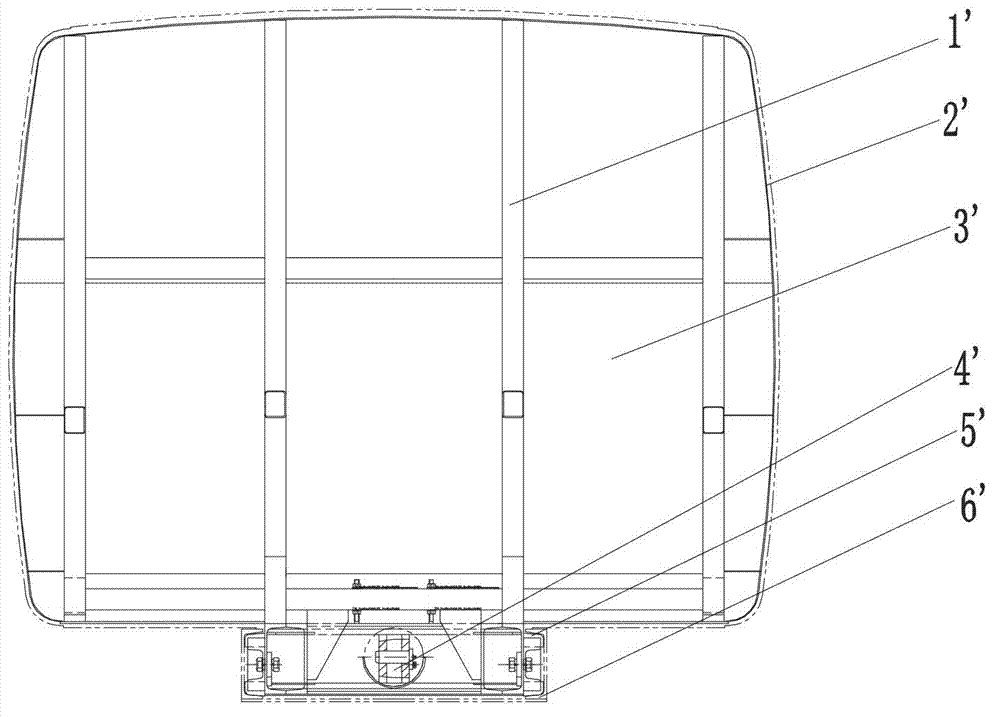

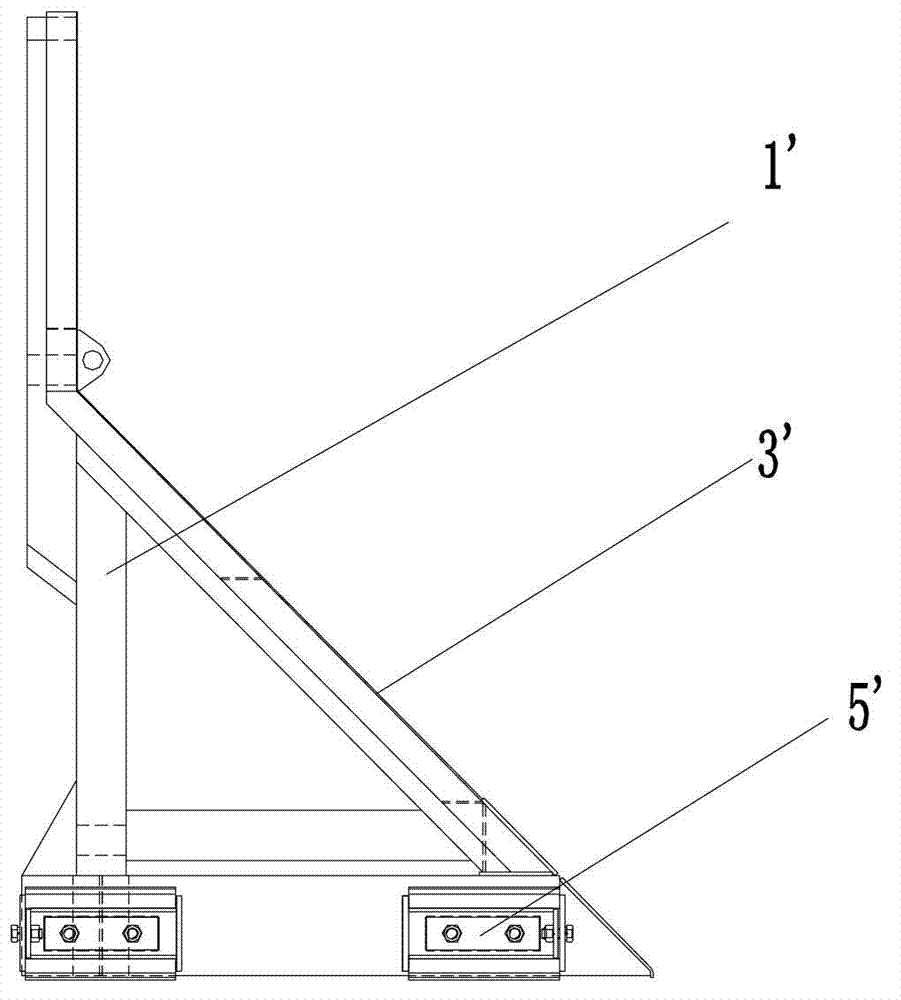

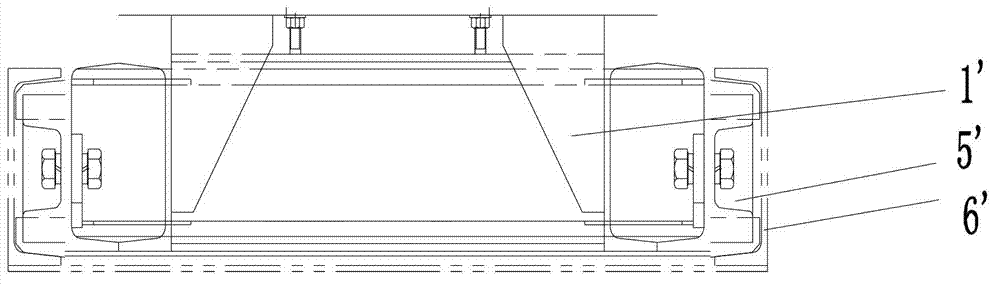

[0035] Such as Figure 4 to Figure 6 As shown, the first embodiment provides a push shovel and a garbage truck with the push shovel. The push shovel is arranged in the compartment of the garbage truck, and the push shovel includes a push shovel body, and the push shovel body includes a bracket 1 and a cover panel arranged on the bracket 1 . Wherein the covering panel comprises a vertical panel on the upper side and an inclined panel 3 on the lower side. The bracket 1 includes a horizontal support portion 12 and a vertical support portion 13 which are vertically connected to each other. The inclined plate 3 includes a first support plate 31 and a second support plate 32 , the first support plate 31 and the second support plate 32 are bent and connected to form an angle. The connection line between the first support plate 31 and the second support plate 32 is parallel to the connection line between the horizontal support portion 12 and the longitudinal support portion 13 , and...

no. 2 example

[0044] Such as Figure 7 As shown, the roller 22 of the dozing shovel is arranged at the bottom of the dozing shovel body and rolls on the bottom plate 4 of the compartment of the garbage truck, which realizes the conversion of sliding friction into rolling friction and reduces the frictional resistance between the dozing shovel and the carriage. Roller 22 front portions also can be provided with the rubbish baffle for cleaning rubbish.

[0045] Preferably, the garbage truck is provided with a guide device for guiding the movement of the dozer body relative to the carriage. In the second embodiment, the guiding device is a sliding rail 10 and a sliding block 9 . Specifically, the slide rail 10 is a channel steel with an opening facing the side of the horizontal support portion 12, and the slide rail 10 is arranged on the carriage. Specifically, the slide rail 10 is a channel steel with an opening facing the side of the horizontal support portion 12, the outer side of the cha...

no. 3 example

[0048] Such as Figure 8 As shown, according to the third embodiment of the present invention, the rollers 23 of the dozer are arranged at the bottom of the dozer body, and the track 52 is arranged on the floor 4 of the compartment of the garbage truck. The roller 23 includes a groove arranged along its circumference, and the track 52 cooperates with the groove. The rail 52 in the third embodiment has a trapezoidal cross section and is welded to the bottom plate 4 of the carriage. Correspondingly, the grooves on the roller 23 are also configured to have a trapezoidal cross-section. The whole push shovel is supported by the rollers 23 and the track 52, which converts sliding friction into rolling friction, reduces frictional resistance, and sets the cross-sectional shape of the track 52 as a trapezoid, which can prevent garbage from staying in dead corners. Roller 23 front portions also can be provided with the rubbish baffle for cleaning rubbish.

[0049] The bulldozer of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com