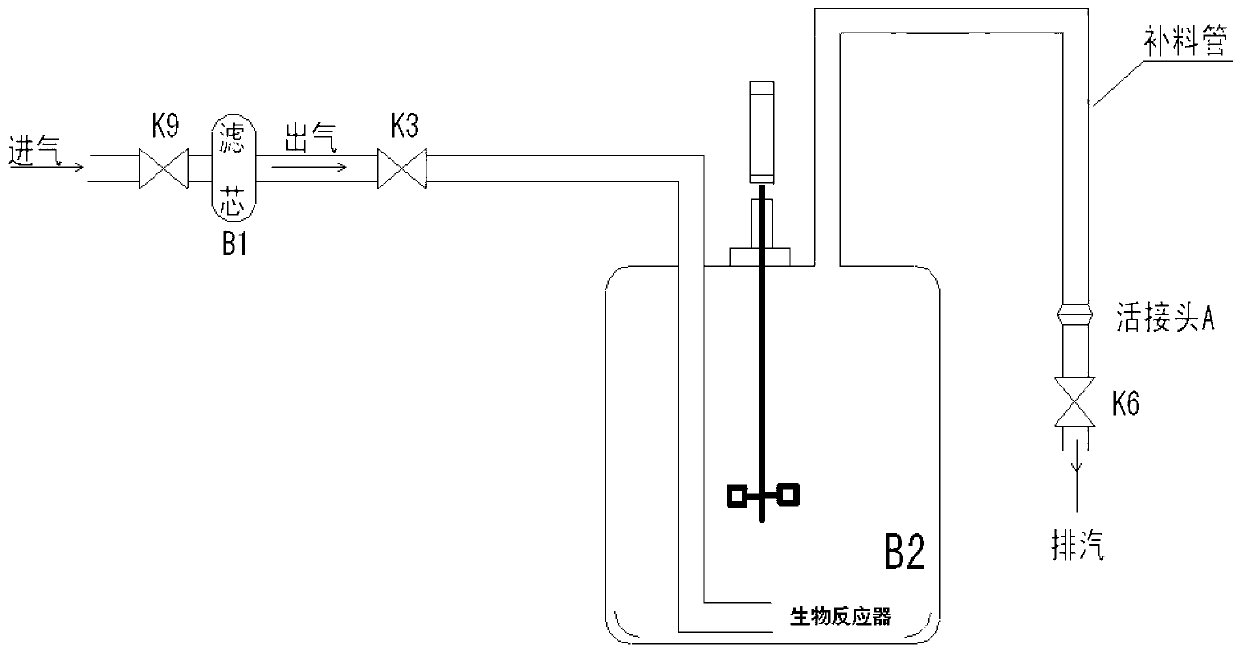

Pollution-free sterilizing system for air intake and material feeding of bioreactors and control method thereof

The technology of a bioreactor and a sterilization system is applied in the field of non-polluting sterilization systems of bioreactors, which can solve the problems of shortening the service life of the filter element, the temperature is not stable enough, and the filter element is damaged, and achieves the effect of prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

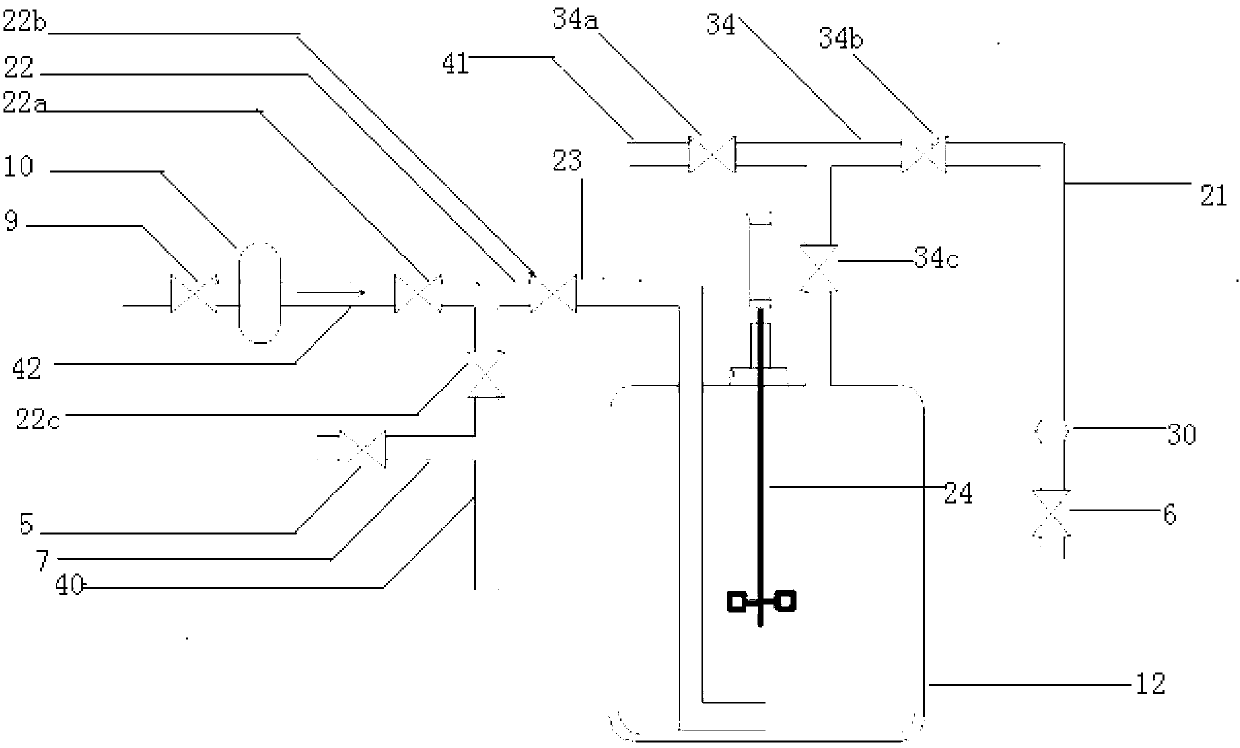

[0064] In a preferred embodiment of the present invention, as figure 2 As shown, a pollution-free sterilization system for bioreactor air intake and feeding is provided, including: a bioreactor 12, an air intake (steam) device and a feeding device that are respectively connected to the bioreactor 12; wherein , the intake (steam) device includes an intake (steam) pipeline 23, an intake (steam) valve 9 and an intake filter 10, and the intake filter 10 is located between the intake (steam) valve 9 and the bioreactor 12 Between; feeding device includes feeding pipeline 21, exhaust valve 6 and union 30, and union 30 connects feeding pipeline 21 and exhaust valve 6; between bioreactor 12 and intake filter 10 A three-way device 22 is provided, and the three-way device communicates with the bioreactor 12, the intake filter 10 and the pure steam inlet and exhaust branches; the three-way device 22 contains three channel valves, wherein the first channel valve 22a is connected to the i...

Embodiment 2

[0068] In a preferred embodiment, the pipe opening connecting the third channel valve 34c of the three-way structure 34 and the bioreactor 12 is arranged at the top of the bioreactor 12 . Embodiment 2 Various control or application methods of the pollution-free sterilization system for the bioreactor air intake and feeding of the present invention

[0069] When normal high-pressure sterilization of the culture medium of the bioreactor is required, the inlet valve 9, inlet filter 10, valves 22a and 22b are opened, valves 5, 22c, and 34a are closed, and pure steam enters through the inlet filter. In the bioreactor 12, the valves 34b, 34c and 6 are opened, and the steam is exhausted through the steam exhaust branch.

[0070] If the online detection of the filter element of the intake filter fails due to high pressure due to the number of uses, pressure, etc., then close the valve 22b, open the intake valves 9, 22a, 22c and the exhaust valve 5, the intake device and the bioreactor...

Embodiment 3

[0076] Embodiment 3 Application of the bioreactor air intake and feeding of the present invention uses a pollution-free sterilization system to sterilize the medium in the bioreactor

[0077] 1. Empty elimination

[0078] Refers to the purging and disinfection of the bioreactor, the filter housing of the intake filter (the intake filter does not add a filter element, only the filter housing), the exhaust valve and all pipelines, and the order of steam intake is intake filter filter housing, bioreactor, exhaust valve and all pipelines. When the temperature of the reactor rose to 121°C, the timing was started for emptying. At this time, do not add air intake filter element, pH probe, dissolved oxygen probe, and do not start stirring. Under the condition that the temperature is kept constant, all the pipelines (including feeding pipes, exhaust pipes, etc.) are purged and sterilized with pure steam. After disinfection, close all valves and wait for use.

[0079] Second, the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com