Construction method of cast-in-place pile by artificial digging hole under extreme cold climate in winter

A technology for artificial hole digging and cast-in-place piles, which is applied to sheet pile walls, infrastructure engineering, construction, etc., can solve the problem of being in a standstill state, the difficulty of manual hole digging operation, the inability of manual hole digging operation and concrete mixing, transportation and pouring operation, etc. problems, to achieve the effect of ensuring the construction quality and speeding up the construction period of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A kind of construction method of artificially digging holes in cast-in-place pile in severe cold climate in winter of the present invention, its steps are as follows:

[0022] (1) When designing the pile diameter, reduce the number of piles and increase the pile diameter on the basis of bearing capacity or uplift resistance, shear resistance and settlement deformation that meet the design and specification requirements;

[0023] (2) The personnel organization selects digging operators who have experience in winter construction in the north, and is equipped with winter construction labor protection supplies necessary for manual digging operations. In addition, a soft ladder is set at the opening of the digging operation. After the depth exceeds 10 meters, The air quality in the hole should be tested and ventilated before each hole operation;

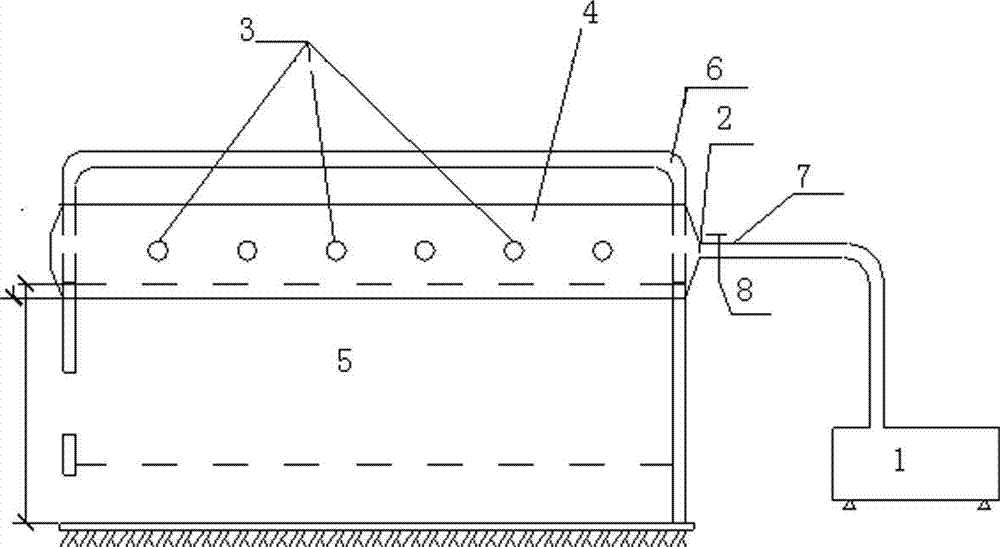

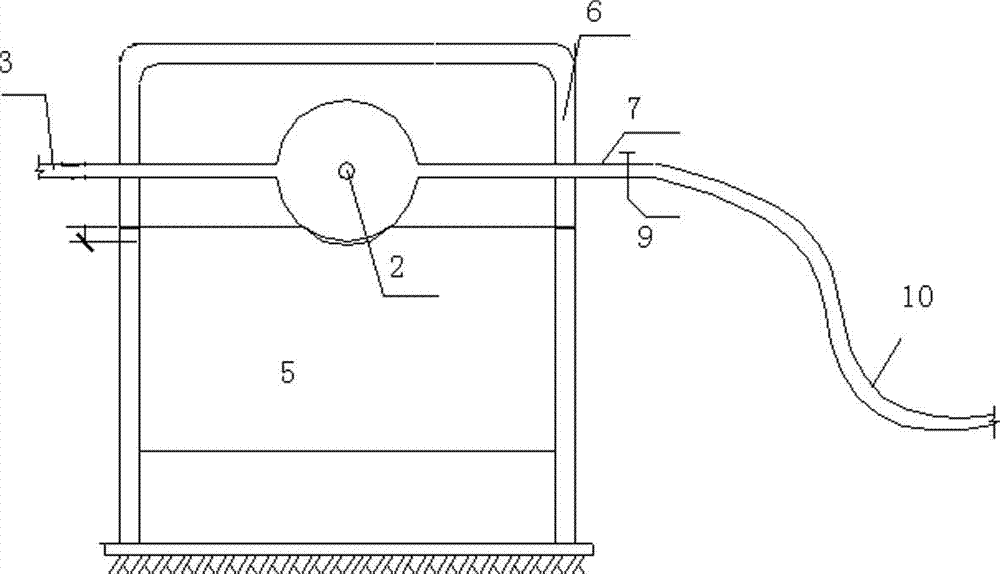

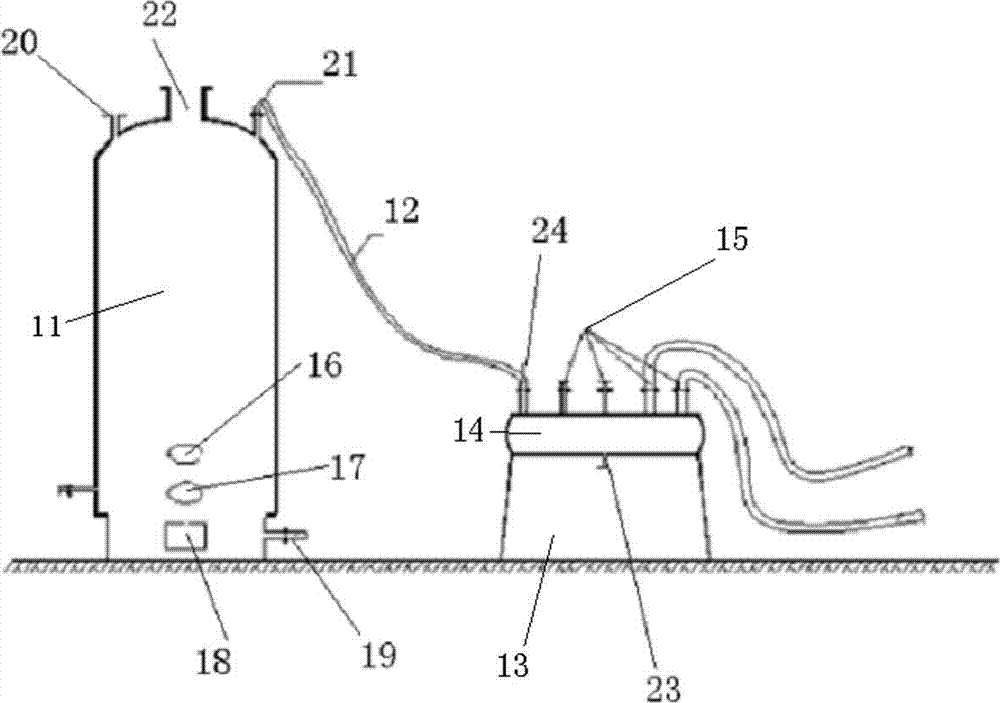

[0024] (3) Hole-digging tools and pile core concrete mixing are all carried out under heating conditions. The retaining wall conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com