Pneumatic deep groove digging device

A power device, deep groove technology, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of not significantly improving the slag discharge capacity, unable to ensure the smooth progress of construction, unable to achieve the role of assisting slag discharge, etc. Clever, stable work, avoid occupancy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further illustrated and explained below in conjunction with the examples.

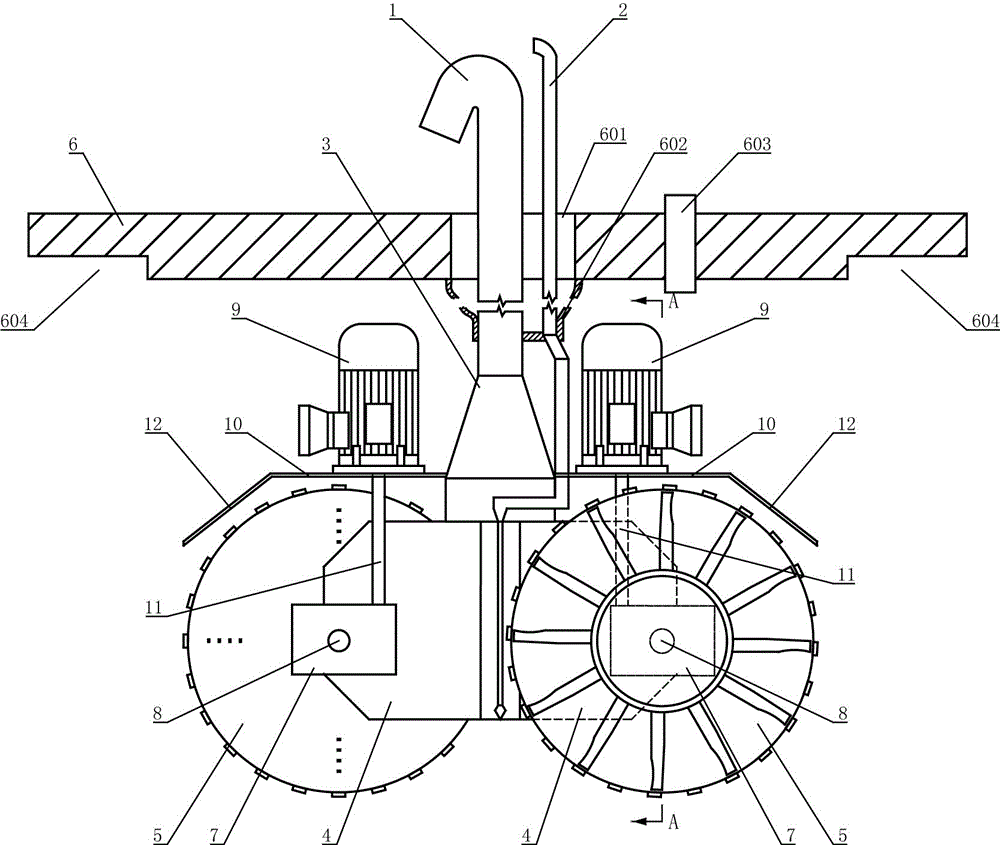

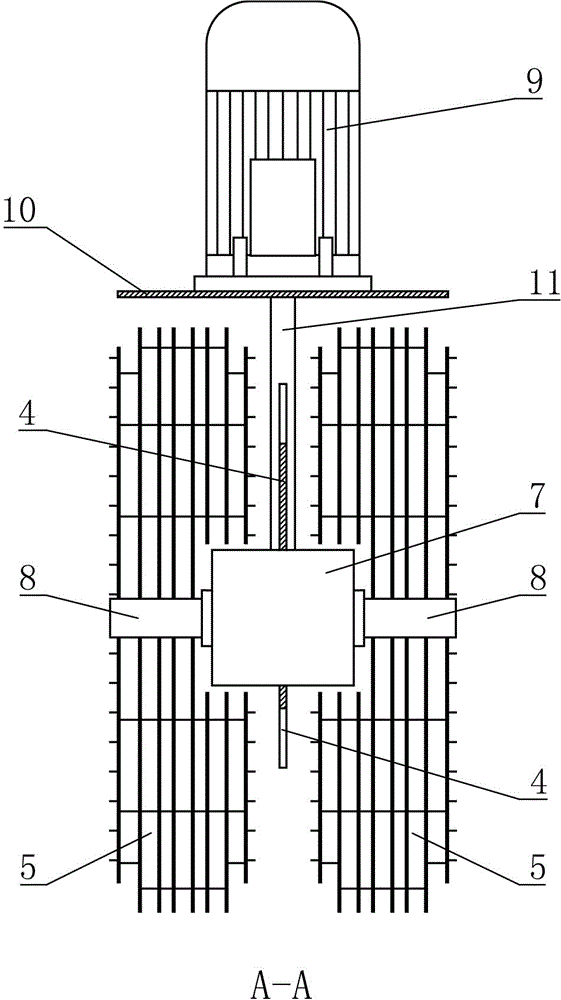

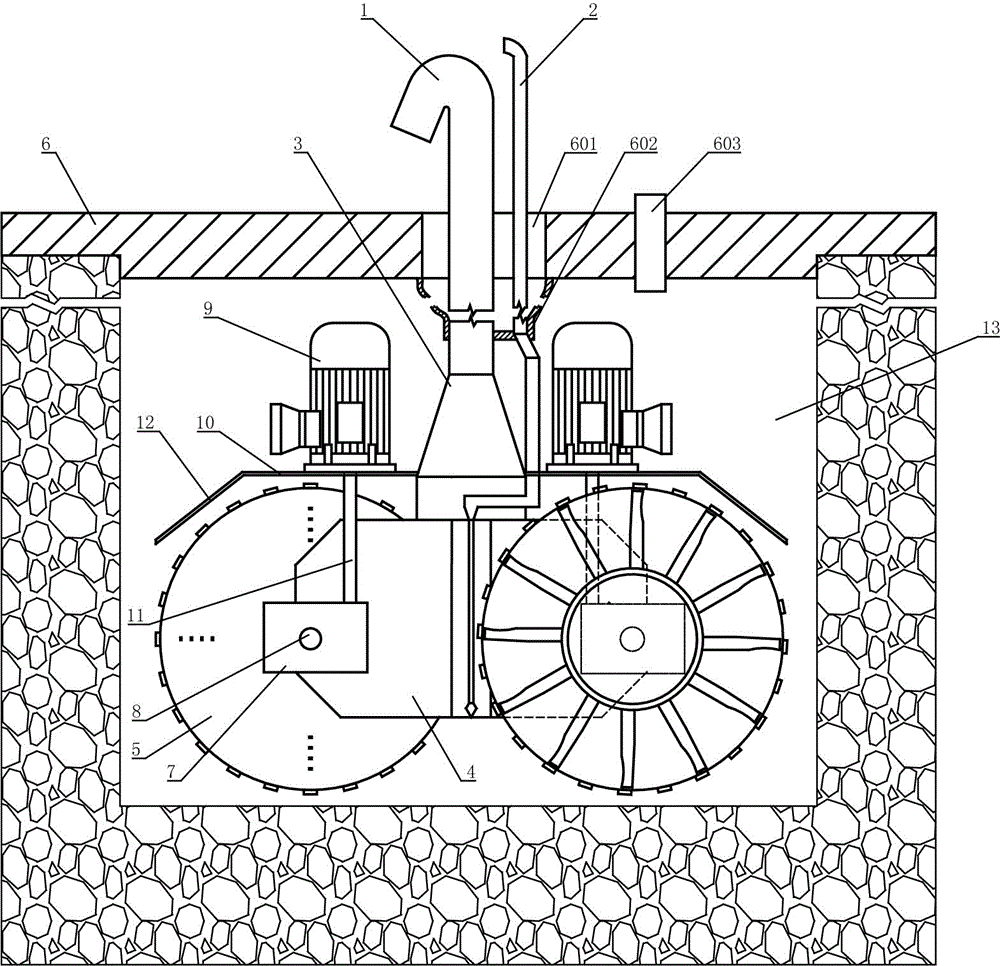

[0025] Pneumatic deep groove excavation device of the present invention, as figure 1 As shown, it includes a conduit 1, a horn-shaped tubular body 3 fixedly connected to the end of the conduit 1 through a small mouth end, and the upper part passes through the side wall of the horn-shaped tubular body 3 and is connected to the air intake pipe on the outside of the horn-shaped tubular body 3 and the conduit 1 2. The sealing cover plate 6 set on the conduit 1 and the intake pipe 2 through the central through hole 601, the fixed frame 4 fixedly connected to the large mouth end of the trumpet-shaped pipe body 3, and the cutting wheel 5 arranged on the fixed frame through bearings; The sealing cover plate 6 generates air pressure inside by sealing the notch of the foundation pit 13, which strengthens the power of slag discharge from the inside; after the upper part of the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com