Fan inner volute

A volute and fan technology, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of uneven air output and sometimes no air, so as to achieve uniform air output, consistent air volume, and reduce noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

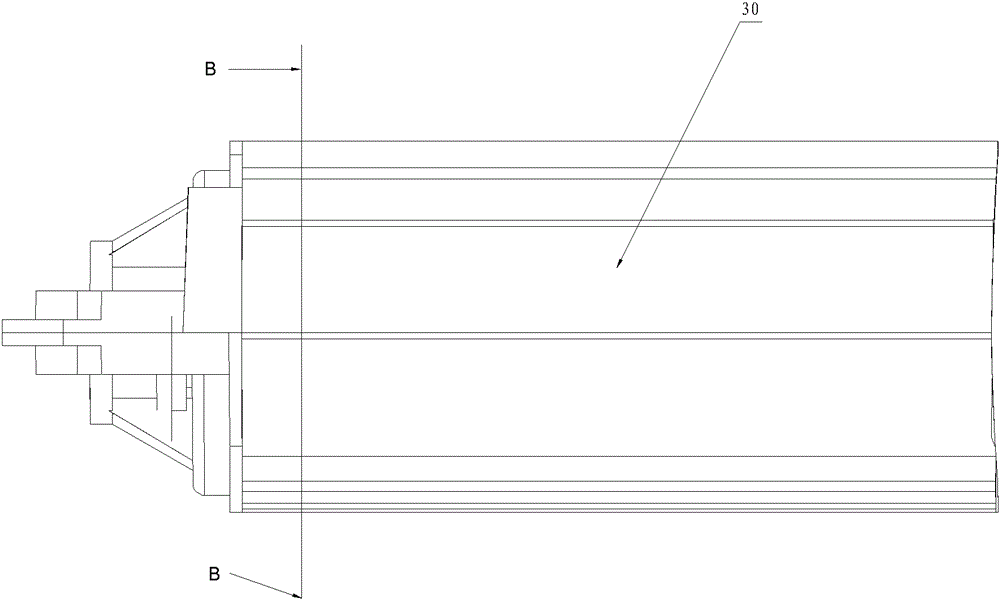

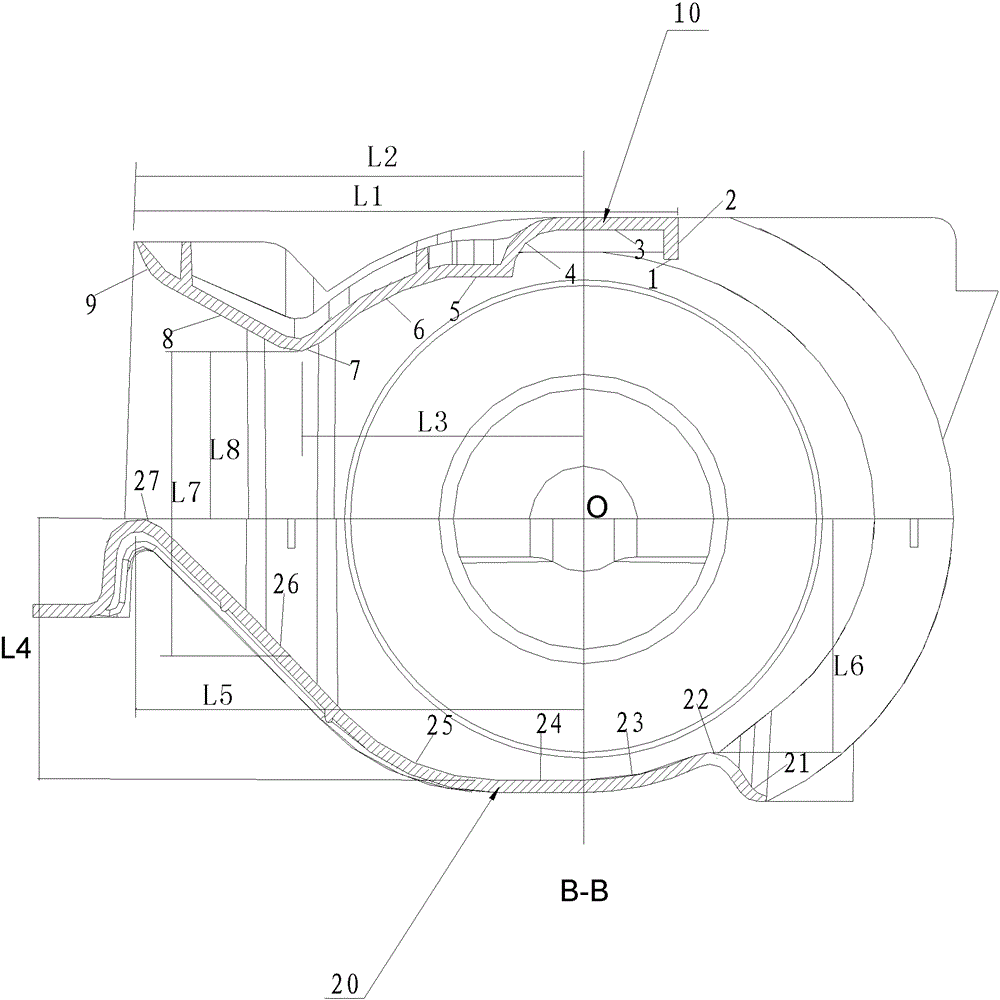

[0025] Such as figure 1 , figure 2 As shown, in the upper cover 10, the straight side 1 with a length of 1.97 mm is connected at 90 degrees to the straight side 2 with a length of 4 mm, and the straight side 2 is connected at a right angle to 90 degrees with the straight side 3 with a length of 14.55 mm. Connect with the arc side 4 with a radius of 6.23mm (referred to as R6.23mm). The curved side 4 is connected to the curved side 6 of R36.29mm via the straight side 5 with a length of 8.97mm, and the curved side 6 is connected to the curved side 7 of R5mm. The curved side 7 is connected to the curved side 9 of R6 mm via the straight side 8 with a length of 18.11 mm. The total length L1 of the upper cover is 74.35 mm. The horizontal dimension L2 between the axis O of the volute and the air outlet of the upper cover is 61.37mm, and the horizontal distance L3 between the arc length center of the arc edge 7 and the axis O of the volute is 38.67mm.

[0026] In the lower cover 2...

Embodiment 2

[0030]In the upper cover 10, the straight side 1 with a length of 1.97±1 mm is connected at 90 degrees to the straight side 2 with a length of 4±1 mm, and the straight side 2 is connected with the straight side 3 with a length of 14.55±3 mm at a right angle of 90 degrees, and the straight side 3 is connected to the arc side 4 with a radius of 6.23±2mm (abbreviated as R6.23±2mm). The curved side 4 is connected to the curved side 6 of R36.29±5mm via the straight side 5 with a length of 8.97±2mm, and the curved side 6 is connected to the curved side 7 of R5±1mm. The curved side 7 is connected to the curved side 9 of R6±1 mm via the straight side 8 with a length of 18.11±4 mm. The total length L1 of the upper cover is 74.35±5mm. The horizontal dimension L2 between the axis O of the volute and the air outlet of the upper cover is 61.37±5mm, and the horizontal distance L3 between the arc length center of the arc edge 7 and the axis O of the volute is 38.67±5mm.

[0031] In the low...

Embodiment 3

[0037] The difference between this embodiment and the above-mentioned embodiments lies in that five brackets (not shown) are respectively provided on the contact surfaces where the upper cover 10 and the lower cover 20 are engaged with each other. When assembling this embodiment, the five brackets (not shown) on the upper cover 10 correspond to the five brackets (not shown) on the lower cover 20 , and they are connected in pairs. In this embodiment, the internal support strength is increased by docking brackets (not shown), so that the structure of this embodiment is firmer and less likely to be damaged during use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com