Plugging bolt

A technology of bolts and fastening bolts, applied in pressure vessels, engine seals, engine components, etc., can solve problems such as large volume, achieve high repair efficiency, easy operation, and ensure smooth completion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

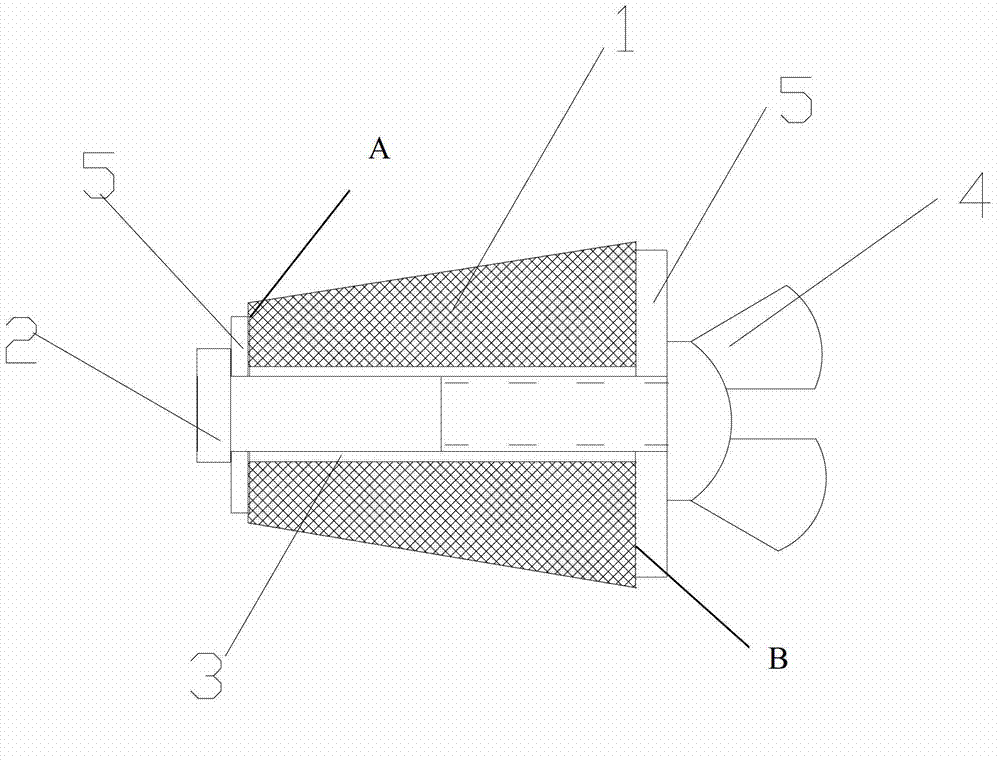

[0013] Hereinafter, in combination with preferred embodiments, the specific implementation manner provided according to the present invention is described in detail as follows: See the drawings for details, a plugging plug, including a flexible plugging plug 1 and a fastening bolt 2, the flexible plugging plug A through hole 3 is provided in the middle of the sub, and a fastening bolt with an ingot nut 4 penetrates through the through hole. The longitudinal cross-sectional shape of the flexible plugging plug is a truncated cone with an isosceles trapezoid. The flexible plugging plug is made of oil-resistant rubber or plastic or engineering plastics. The diameter of the lower bottom B of the flexible plugging plug is Φ16mm-Φ35mm, and the diameter of the upper bottom A is Φ8mm-Φ20mm. Washers 5 are respectively arranged between the two ends of the flexible plugging plug and the fastening bolt. The fastening bolt has an interference fit with the through hole, and its diameter is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com