Method for carrying out silk screen sintering by utilizing silk screen sintering furnace

A technology of sintering furnace and wire mesh, which is applied in furnaces, muffle furnaces, cooking furnaces, etc., can solve the problems of increasing production costs, wasting isolation layers, reducing work efficiency, etc., and achieves the effect of high strength of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The first step is to prepare materials

[0061] Stack the multi-layer mesh sheets that need to be sintered neatly according to the process requirements, and fix the four corners together by spot welding to form a sintered mesh;

[0062] The second step, network

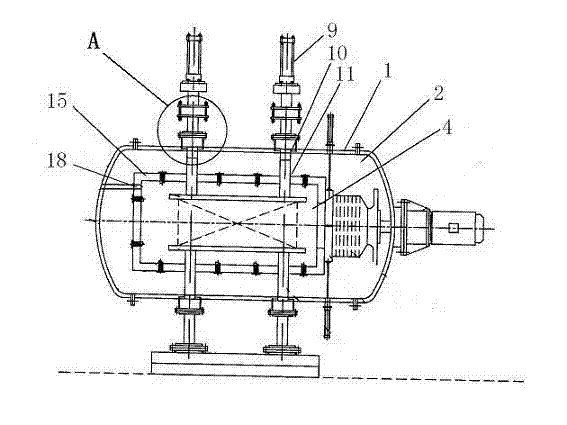

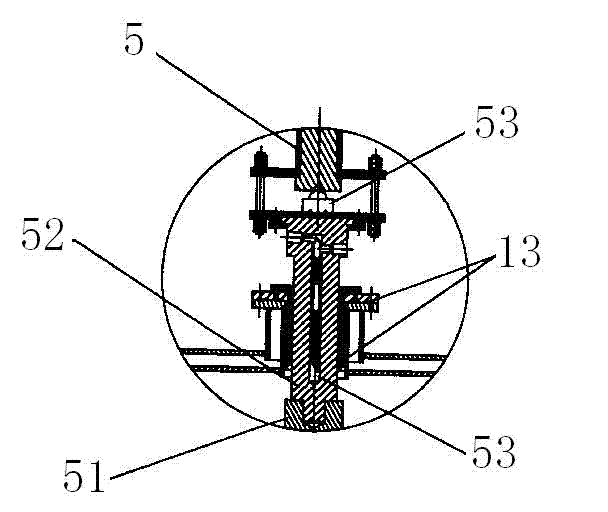

[0063] Stack multiple sintered nets layer by layer on the material pallet, with an isolation layer between each sintered net, place a material pressure plate on the top of the sintered net, and place the stacked material pallet, sintered net and The material pressing plate is loaded into the sintering furnace;

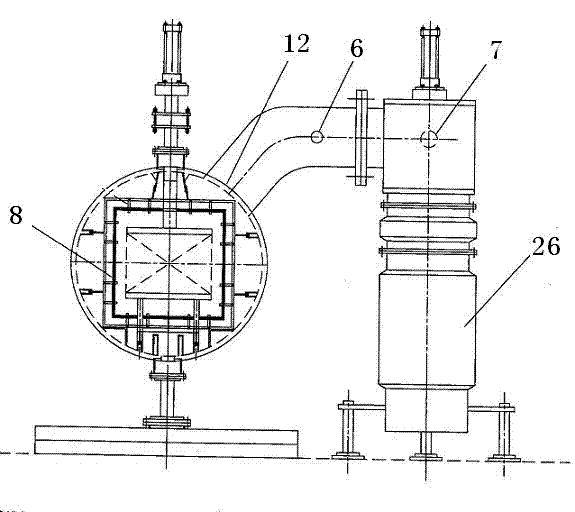

[0064] The third step is to vacuum

[0065] Vacuum the sintering furnace so that the pressure in the sintering furnace is 1.3×10 -3 Pa;

[0066] The fourth step, heating up

[0067] Heating by the heating device, when the temperature in the sintering chamber rises to 295°C, inject hydrogen into the sintering chamber to keep the pressure in the sintering chamber at 39 Pa, continue heating to raise t...

Embodiment 2

[0083] In the third step vacuum stage, the pressure in the sintering furnace is 6×10 -4 Pa;

[0084] In the fourth step of heating and heating stage, when the temperature in the sintering chamber rises to 305°C, hydrogen gas is introduced into the sintering chamber so that the pressure in the sintering chamber is at 41 Pa, and the temperature in the sintering chamber is raised to 1200 by continuing heating. ℃;

[0085] In the fifth step of pressurization, the pressure at the sintering network is 1.5 kg / cm2;

[0086] In the sixth step insulation stage, keep pressure and temperature for 4 hours;

[0087] In the seventh step, the temperature is naturally lowered and the pressure is removed, and the temperature is slowly lowered to 1120°C;

[0088] In the eighth step heat preservation stage, continue heat preservation for 1 hour;

[0089] In the ninth step, the rapid cooling stage, the pressure of the cooling gas introduced is 2 standard atmospheres, and the temperature drops ...

Embodiment 3

[0093] In the third step vacuum stage, the pressure in the sintering furnace is 6×10 -4 Pa;

[0094] In the fourth step of heating and heating stage, when the temperature in the sintering chamber rises to 298°C, hydrogen gas is introduced into the sintering chamber so that the pressure in the sintering chamber is at 39.5 Pa, and the temperature in the sintering chamber is raised to 1260°C;

[0095] In the fifth step of pressurization, the pressure at the sintering network is 0.85 kg / cm2;

[0096] In the sixth step insulation stage, keep the pressure and temperature for 7 hours;

[0097] In the seventh step, the temperature is naturally lowered and the pressure is removed, and the temperature is slowly lowered to 1090°C;

[0098] In the eighth step heat preservation stage, continue heat preservation for 1.4 hours;

[0099] In the ninth step, in the rapid cooling stage, the pressure of the cooling gas introduced is 1.9 standard atmospheres, and the temperature drops rapidly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com