A method of manufacturing a back-illuminated cmos image sensor

An image sensor and manufacturing method technology, applied in the field of image sensors, can solve the problem of high requirements for deep groove etching equipment, achieve the effects of reducing process complexity, achieving zero mismatch, and reducing process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be further described below in conjunction with the accompanying drawings. Of course, the present invention is not limited to this specific embodiment, and general replacements known to those skilled in the art are also covered within the protection scope of the present invention.

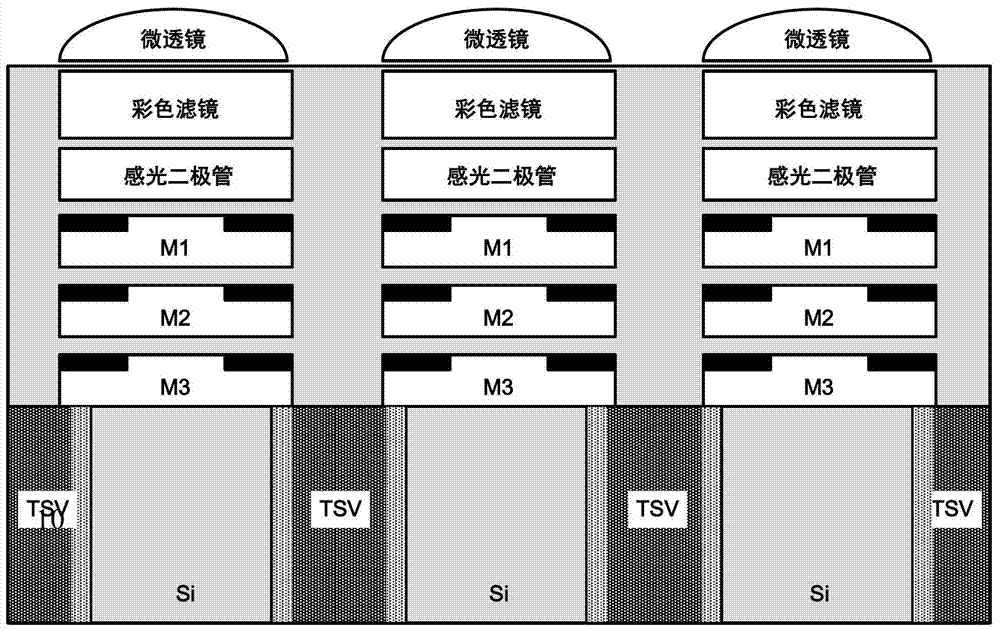

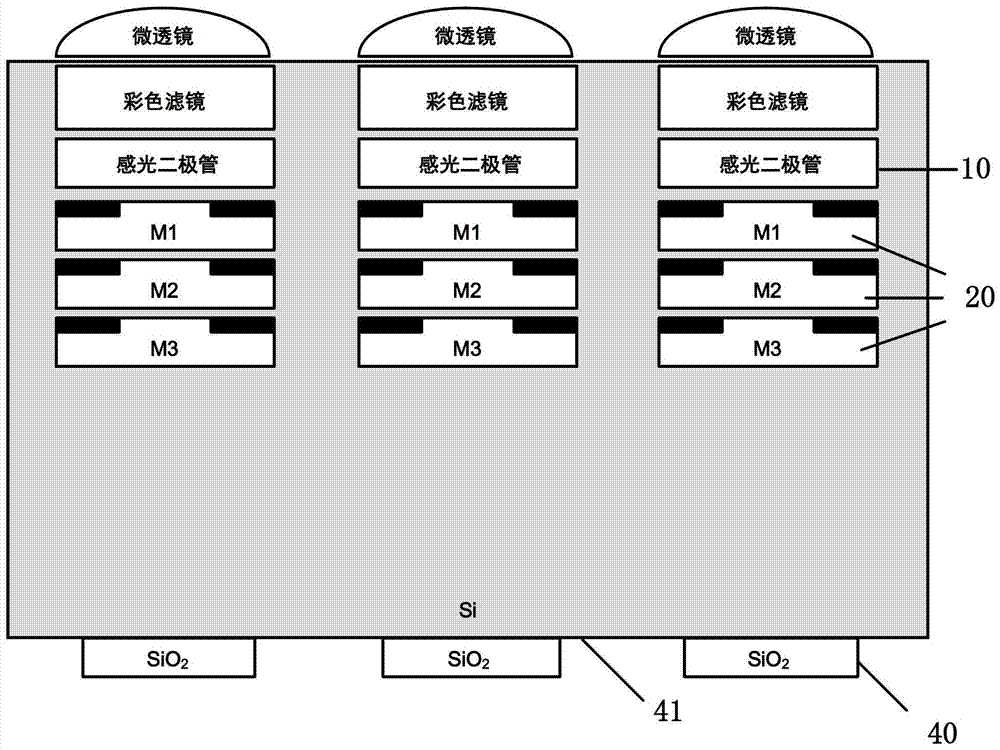

[0022] The following will refer to Figure 2 to Figure 6 A method for manufacturing a back-illuminated CMOS image sensor according to the present invention is described.

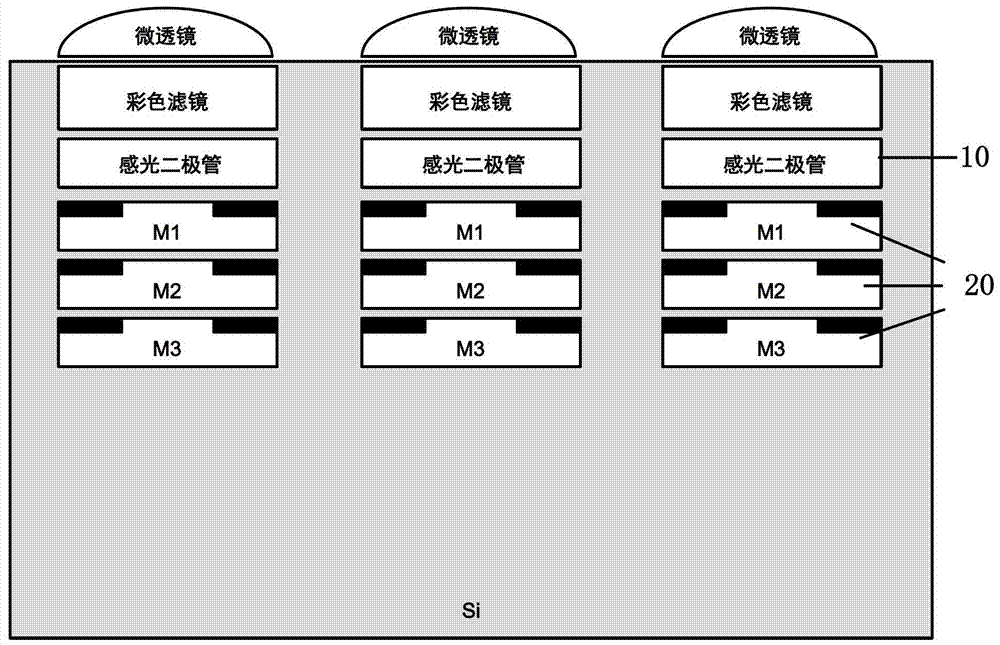

[0023] Please refer to figure 2 , firstly, a silicon substrate is provided, and a photosensitive diode region 10 for light sensing and one or more layers of metal interconnection layers 20 are sequentially formed in the substrate using a conventional back side illumination (BSI, Back Side Illumination) process. In this embodiment Among them, the number of metal interconnection layers 20 formed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com