Vertical countercurrent solid-liquid contact method, method for washing solid particles, method for producing polyarylene sulfide, and device therefor

A technology of polyarylene sulfide and solid particles, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problem of changes in the treatment efficiency of solid-liquid counterflow contact and the uneven settling velocity of solid particles Uniformity and other issues, to achieve the effect of continuous opposite flow contact and full cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

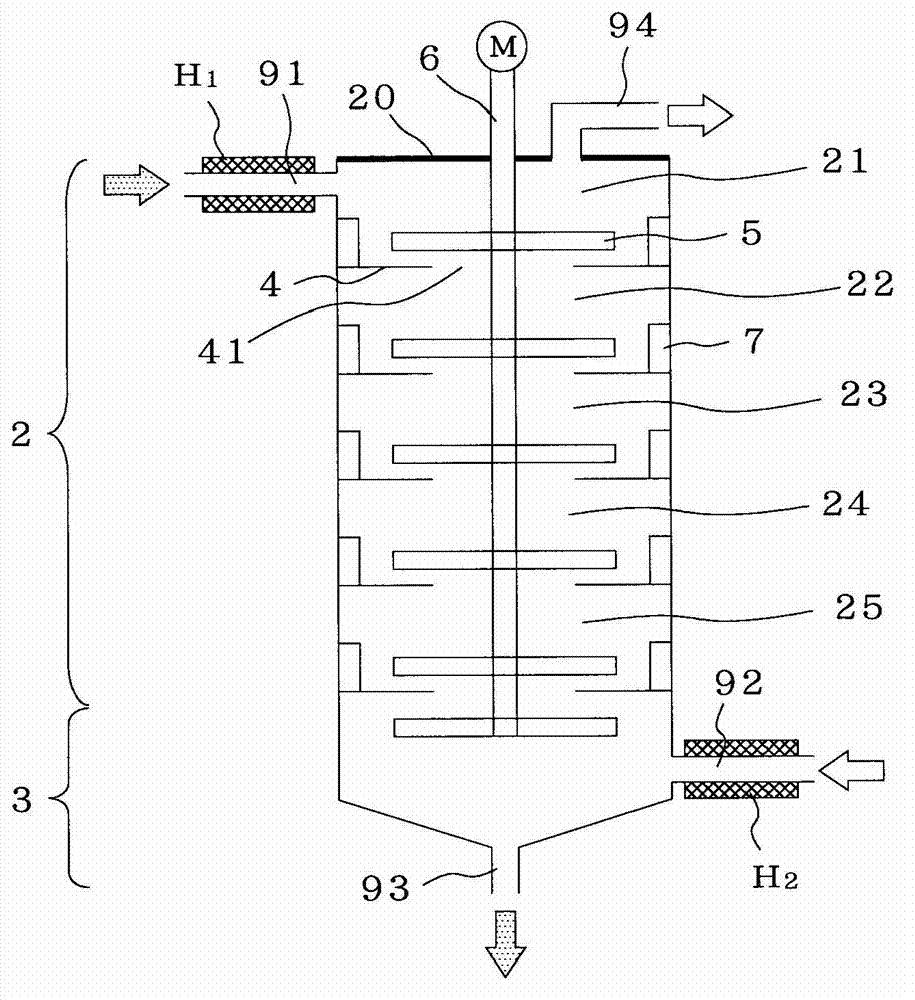

[0152] use figure 1 In the vertical solid-liquid counterflow contact device with the structure shown, the aqueous slurry (PPS slurry) containing PPS particles is washed with ion-exchanged water.

[0153] The PPS slurry used in the Examples and Comparative Examples is obtained by separating the PPS particles from the reaction liquid containing the PPS polymer after the polymerization reaction, and then washing with acetone, and using the recovered PPS particles with a specified ratio of Aqueous acetone solution formed from acetone and water was reslurried to prepare.

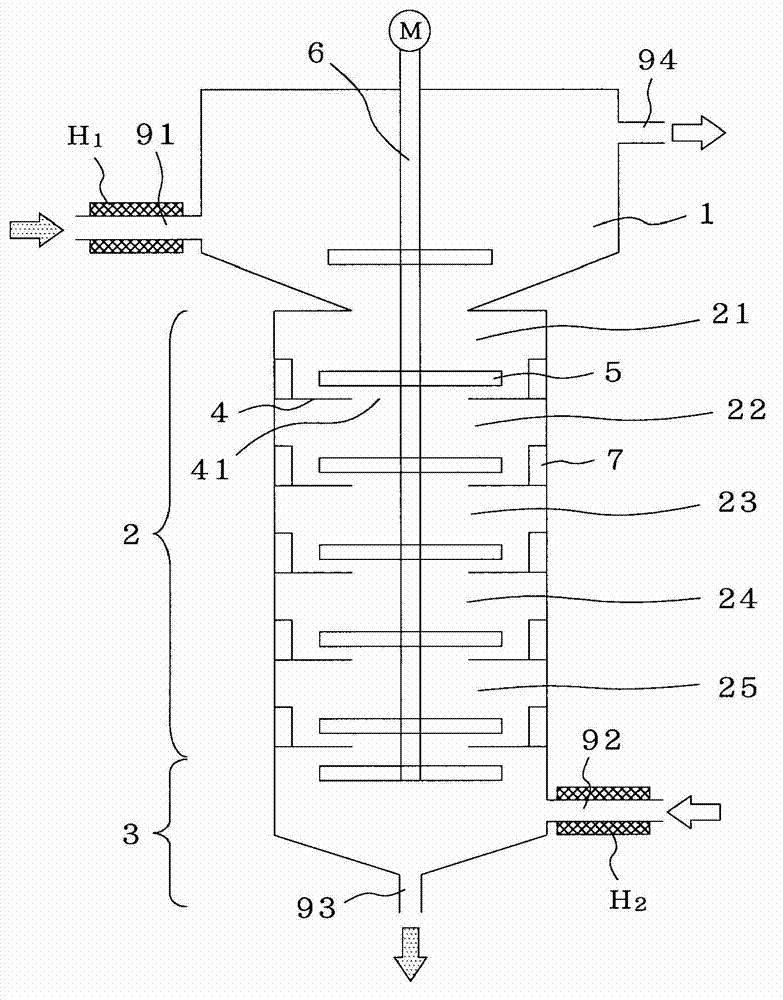

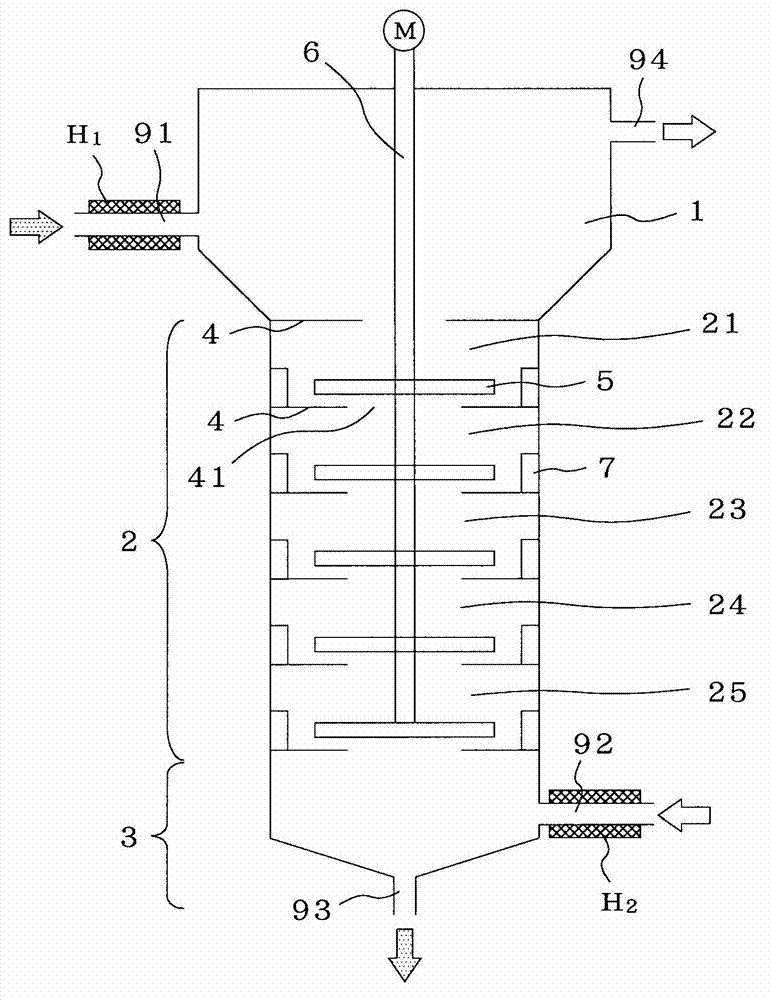

[0154] The vertical solid-liquid counterflow contact device mainly consists of a main body 2 and a bottom 3 made of an acrylic resin plate with an inner diameter of 310mm, the interior of which can be seen through.

[0155] The main body part 2 is divided into stirring chambers 21-25 which are five contact processing chambers. Each stirring chamber is: inner diameter D=310mm, height H=116.3mm (H / D=0.375). An a...

Embodiment 2

[0166] Except that the temperature control unit was not installed on the outer peripheral surface of the liquid supply flow path 92, a vertical solid-liquid counterflow contact device with the same structure as in Example 1 was used to wash the PPS slurry with ion-exchanged water. The temperature of the ion-exchanged water supplied through the liquid supply channel 92 is 26° C., which is close to the outside air temperature in summer.

[0167] Using this vertical counterflow contact device, the stirring shaft 6 was rotated at a stirring speed of 15 rpm. In this stirred state, 550 kg / h of PPS slurry adjusted to a temperature of 40° C. by the temperature control unit was supplied through the solid particle supply flow path 91, and 600 kg / h of ion-exchanged water was supplied through the liquid supply flow path 92 at such ratios. The viscosity of the liquid phase was 1.10 mPa·s, and the viscosity of the ion-exchanged water was 1.08 mPa·s.

[0168] The washing effluent as the upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com