Plasma display panel

A plasma and display panel technology, applied in the direction of AC plasma display panels, discharge tubes, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

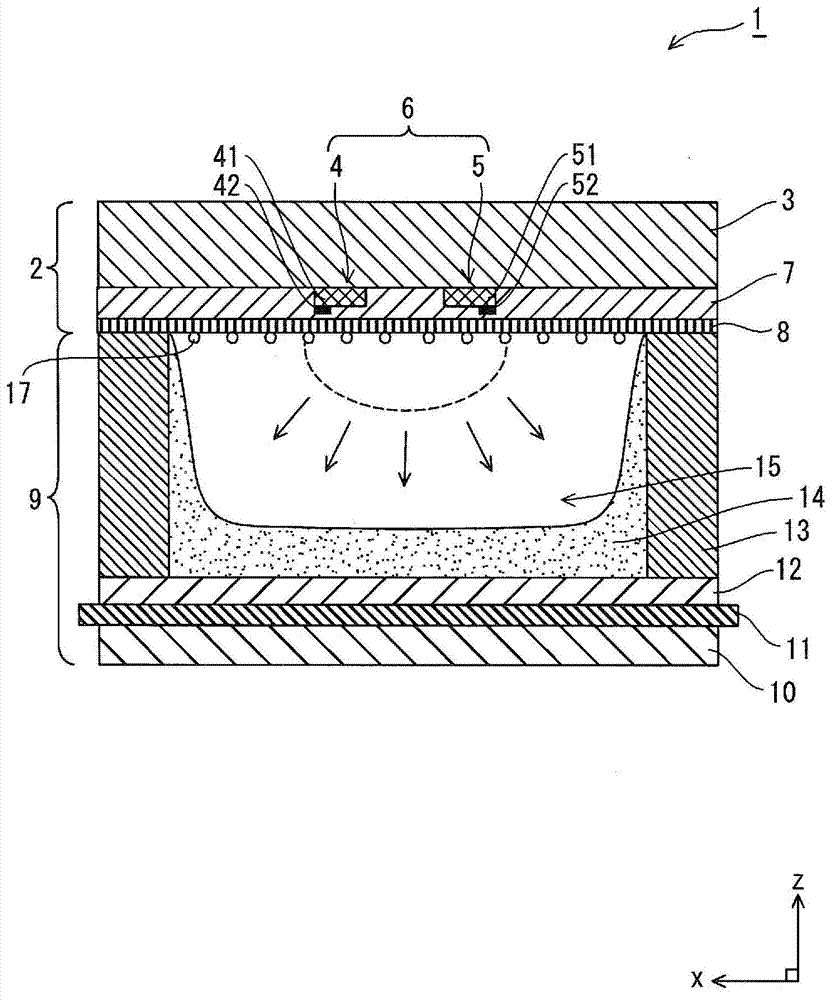

[0056] (overall structure of PDP1)

[0057] figure 1 is a schematic cross-sectional view along the xz plane of PDP1 according to Embodiment 1 of the present invention. Except for the structure around the protective film 8, the PDP1 is generally the same as the existing structure ( Figure 15 )same.

[0058] Here, the PDP 1 adopts the AC type of the NTSC standard example of the 42-inch class, but the present invention can of course be applied to other standard examples such as XGA and SXGA. As a high-definition PDP having a resolution of HD (High Definition, high definition) or higher, for example, the following specifications can be exhibited. When the panel sizes are 37, 42, and 50 inches, they can be set to 1024×720 (number of pixels), 1024×768 (number of pixels), and 1366×768 (number of pixels) in the same order. In addition, a higher resolution panel than the HD panel may also be included. As a panel having a resolution of HD or higher, a full high-definition panel eq...

Embodiment approach 2

[0104] Regarding Embodiment 2 of the present invention, differences from Embodiment 1 will be mainly described. Figure 8 It is a partially enlarged view showing the structure of the PDP 1a according to Embodiment 2 (a structure view near the front panel during driving).

[0105] The basic structure of PDP1a is the same as that of PDP1, but it is characterized in that MgO fine particles 16 with high initial electron emission characteristics are dispersedly arranged on the surface of discharge space 15 facing protective film 8 together with high γ fine particles 17 . The dispersion density of high γ fine particles 17 and MgO fine particles 16 is set so that protective film 8 is not directly seen when protective film in discharge cell 20 is viewed from the Z direction, but is not limited thereto. For example, it may be provided partially or only at the positions corresponding to the display electrode pairs 6 .

[0106] In addition, the mixing ratio of the high γ fine particles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com