Method for manufacturing glassy state core preform

A prefabricated rod and glass state technology, applied in glass manufacturing equipment, glass deposition furnaces, manufacturing tools, etc., can solve problems such as improving optical fiber attenuation, reduce processing steps, reduce preparation costs, and save costs and problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Telecommunications systems generally avoid the use of water peak regions, partly due to the lack of optical waveguide fibers with low water peaks. At present, optical fiber manufacturers have produced low water peak optical fibers through various methods. The development of methods for producing low water peak optical fibers coincides with the development of telecommunication systems which increasingly use all wavelengths between 1300nm and 1650nm. In order for telecommunication systems to fully utilize this wavelength range, the water peak needs to be removed from the optical waveguide fiber.

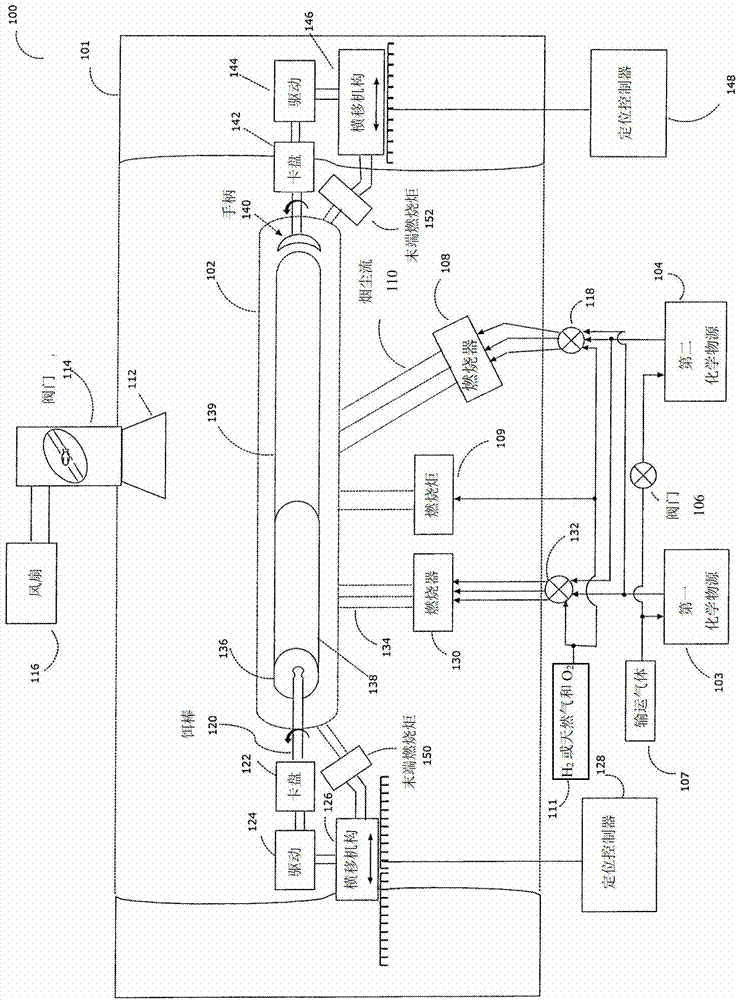

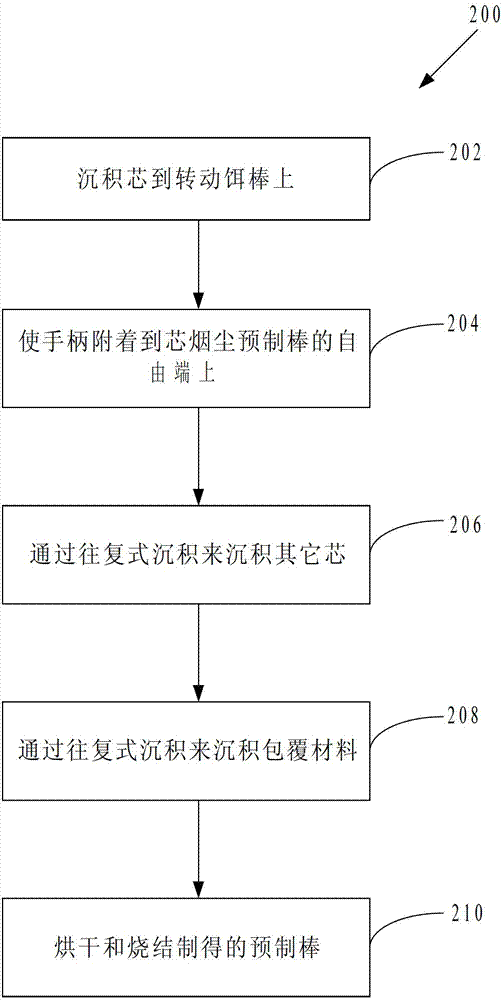

[0023] There are three main methods in general use to prepare optical waveguide preforms. These three technologies have similar methods of vapor generation and oxidation, but differ in the geometry of the substrate on which the oxide soot is deposited:

[0024] (i) Deposition in Tube Method

[0025] These methods include techniques such as MCVD (Modified Chemical Vapor Deposi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com