Preparation method of high-performance recycled aggregate concrete

A high-performance concrete and recycled aggregate technology, applied in the field of concrete, can solve the problems of reduced concrete performance, inability to reuse, and large sludge pollution, etc., and achieve the effects of less mud content, avoiding the aggravation of engineering disasters, and superior concrete performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

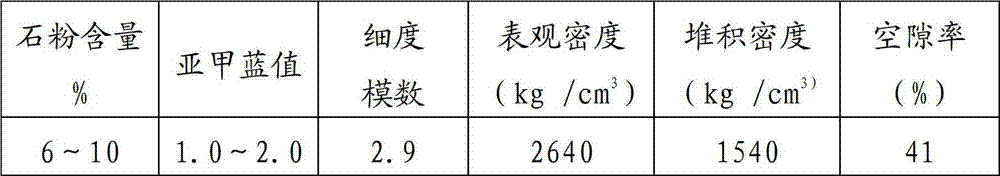

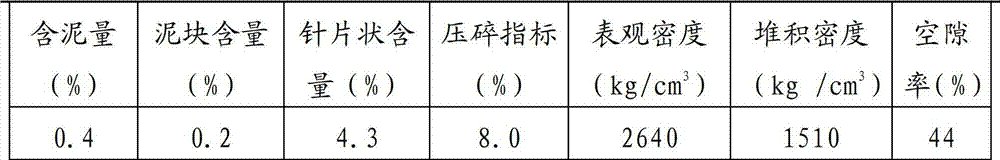

[0035] A method for preparing recycled aggregate high-performance concrete. The waste concrete is crushed to obtain large stones with a particle size of 20-25mm, small stones with a particle size of 5-20mm, and sand with a particle size of less than 5mm. The dust generated in the process is collected by wind; then, the large stones, small stones, and sand are added with polycarboxylic acid water reducing agent, cement and appropriate amount of water, and then the recycled aggregate high-performance concrete is prepared.

[0036] In the present invention, the crushing treatment of the waste concrete includes the following steps:

[0037] S1. Send the waste concrete material to the jaw crusher, and use the jaw crusher to crush; it is worth noting that the waste concrete material will be screened first before sending it, and the majority of the screened components are the waste concrete mud , If these soils are mixed into the subsequent processes, the performance of the recycled aggre...

Embodiment 1

[0050] Use waste concrete to prepare large stones with a particle size of 20-25mm, small stones with a particle size of 5-20mm, and sand with a particle size of less than 5mm, and wind-trap the dust generated during the crushing process;

[0051] Mix 1100kg boulders, 350kg small stones, and 850kg sand, and then add 14kg polycarboxylic acid water reducing agent and 400kg cement at the same time, stir and mix to make recycled aggregate concrete.

Embodiment 2

[0053] Use waste concrete to prepare large stones with a particle size of 20-25mm, small stones with a particle size of 5-20mm, and sand with a particle size of less than 5mm, and wind-trap the dust generated during the crushing process;

[0054] 700kg of big stones, 250kg of small stones, 650kg of sand are mixed and added 7kg of polycarboxylic acid water reducing agent, and at the same time 200kg of cement is added, and mixed to make recycled aggregate concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com