High performance concrete prepared from wastes

A technology of high-performance concrete and waste materials, which is applied in the field of high-performance concrete, can solve problems such as shrinkage and cracking, and achieve the effects of reducing dosage, improving work performance, durability, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

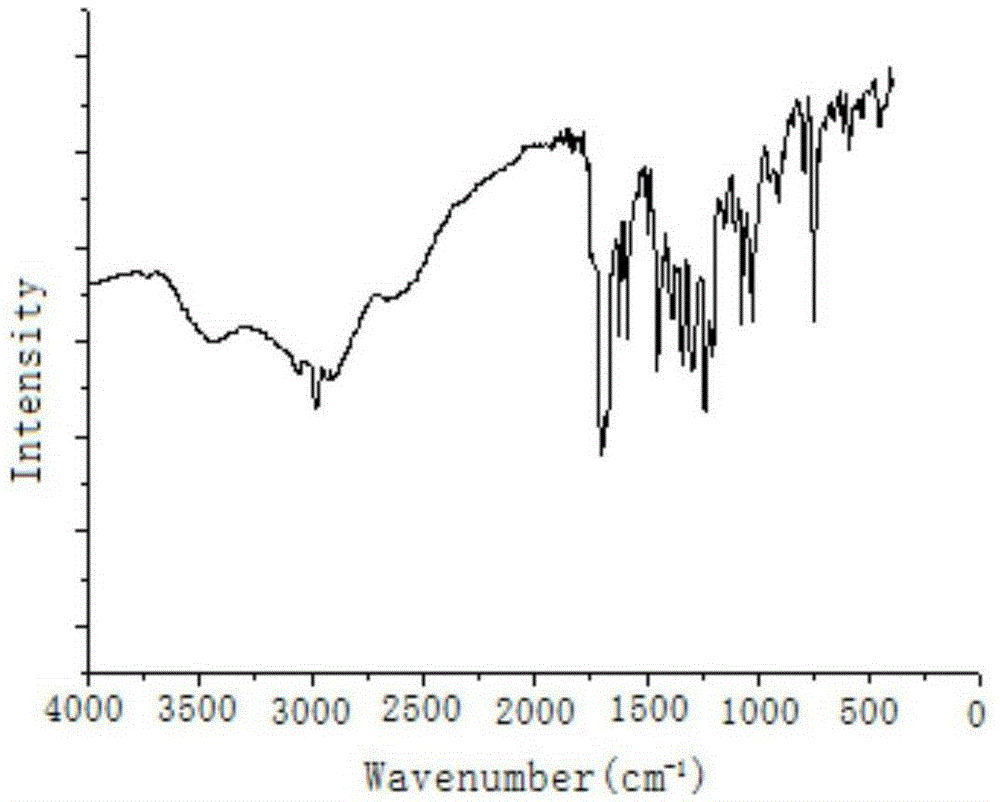

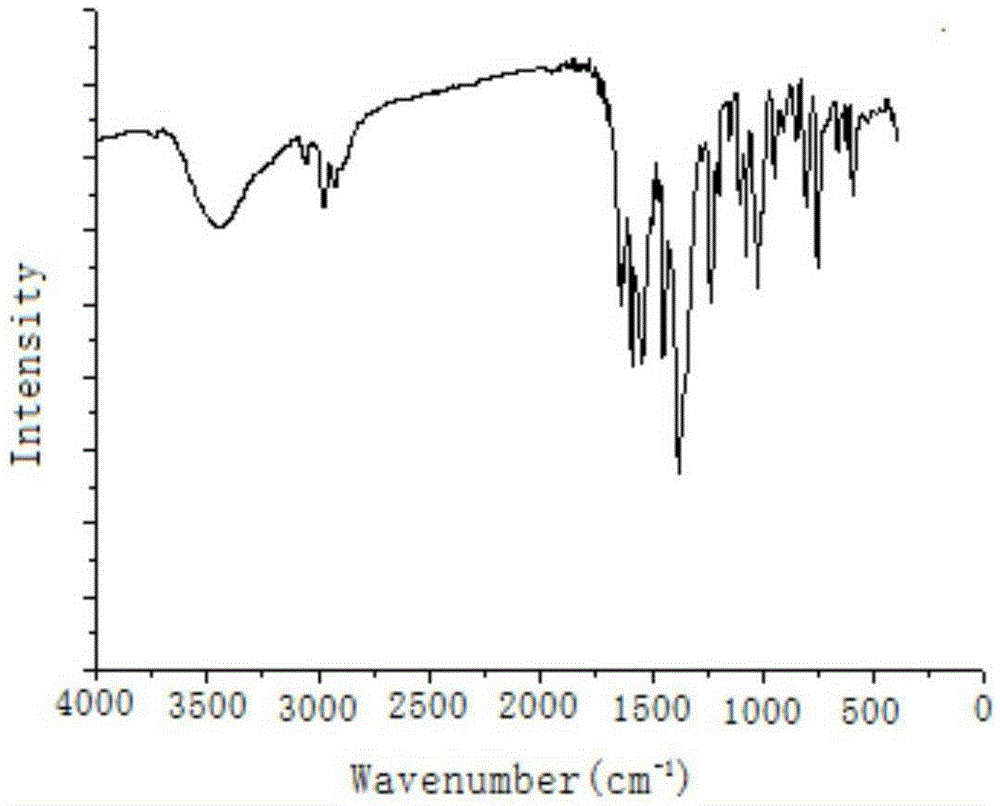

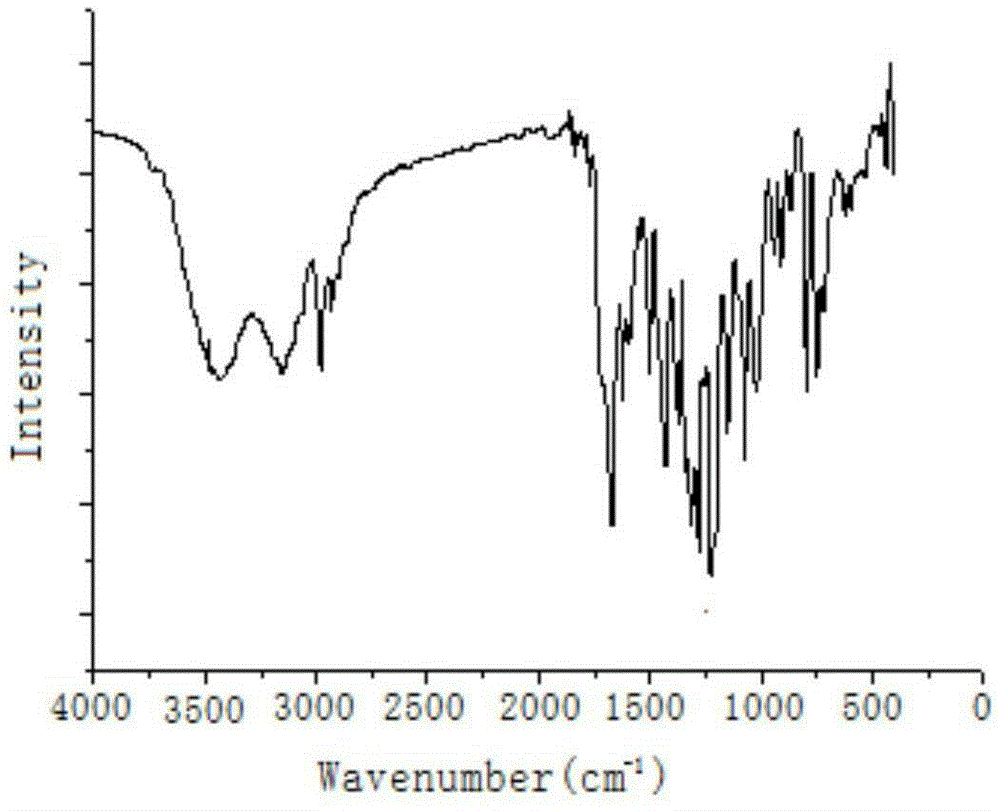

Image

Examples

Embodiment 1

[0048] The mix ratio of the high-performance concrete prepared from waste materials in the embodiment one of table 1

[0049] cement

[0050] Among them, the cement is P.O42.5 Portland cement; the fly ash is Class II fly ash; the mineral powder is S95 grade mineral powder; the water reducing agent is copolymer I; the plastic retaining agent is copolymer II; the anti-segregation agent is copolymer III; the retarder was purchased from Kunshan Guanyuan Jianghong Building Materials International Trade Co., Ltd.

Embodiment 2

[0052] The mix ratio of the high-performance concrete prepared from waste materials in the second embodiment of table 2

[0053] cement

[0054] Among them, the cement is P.O42.5 Portland cement; the fly ash is Class II fly ash; the mineral powder is S95 grade mineral powder; the water reducing agent is copolymer I; the plastic retaining agent is copolymer II; the anti-segregation agent is copolymer III; the retarder was purchased from Kunshan Guanyuan Jianghong Building Materials International Trade Co., Ltd.

Embodiment 3

[0056] The mixing ratio of the high-performance concrete prepared from waste materials in the third embodiment of table 3

[0057] cement

[0058] Among them, the cement is P.O42.5 Portland cement; the fly ash is Class II fly ash; the mineral powder is S95 grade mineral powder; the water reducing agent is copolymer I; the plastic retaining agent is copolymer II; the anti-segregation agent is copolymer III; the retarder was purchased from Kunshan Guanyuan Jianghong Building Materials International Trade Co., Ltd.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com