Low-wavelength dispersibility polymerizability compound, composition of compound and application of compound

A technology of polymeric compounds and polymeric compositions, applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the problem of lower birefringence of liquid crystal mixtures, impracticality, increased thickness of polymer films, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

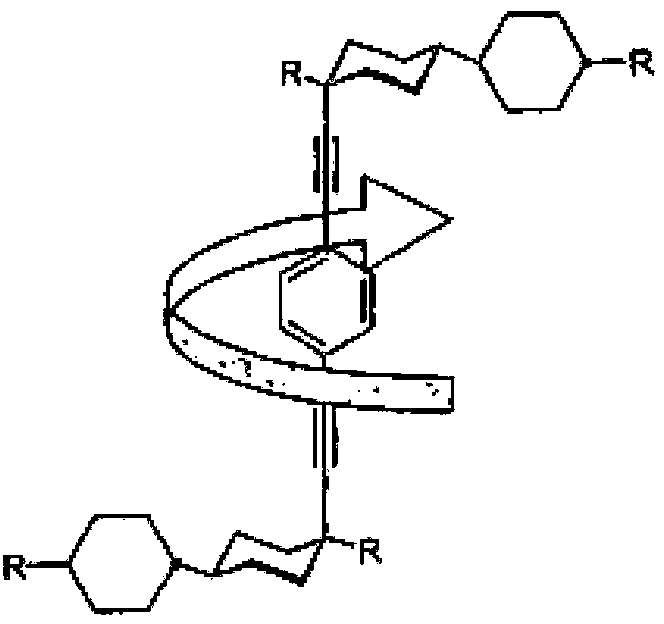

[0073] Example 1: Polymeric compound

[0074] The synthetic route for preparing compound (Ia-1-1) is shown below:

[0075]

[0076] Its specific process steps are as follows :

[0077] 1) Synthesis of the compound of formula 1.1

[0078] Add 62g of 4-iodobenzoic acid, 20g of 2,3-dicyanohydroquinone, a catalytic amount of DMAP (4-dimethylaminopyridine) and 400ml of DCM (dichloromethane) into a 1000ml three-necked flask. Add 60 g of DCC (1,3-dicyclohexylcarbodiimide) dropwise to the above solution at room temperature, and keep the reaction at room temperature for 5 hours. Filtration, washing, drying, rotary evaporation to remove the solvent, and column chromatography yielded 45 g of the product, which was a compound of formula (1.1).

[0079] 2) Synthesis of compounds of formula (1.2)

[0080] The synthesis method of the compound of formula (1.2) has been described in WO2010020312.

[0081] 3) Synthetic compound of formula (1)

[0082] Add the compound of form...

Embodiment 2

[0098] Example 2: Polymerizable composition and optically anisotropic body

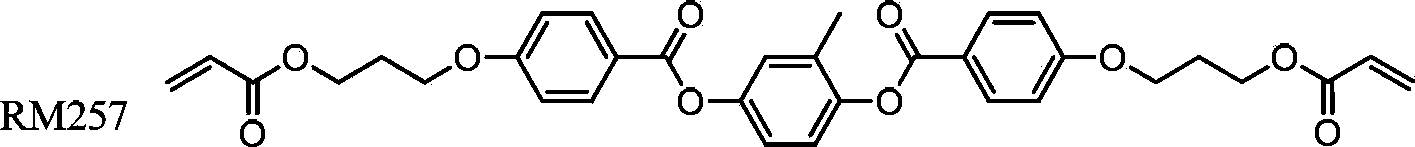

[0099] The structure of the commercially available polymeric liquid crystal compound RM257 (Merck KgaA, Darmstadt, Germany) is shown in the figure below, and the Δn of the compound 450 / Δn 546 About 1.115.

[0100]

[0101] A polymeric composition PL-1 was prepared, wherein RM257 accounted for 50% by weight, and the compound (Ia-1-1) of Example 1 accounted for 50% by weight. A homogeneous polymerizable composition PL-1 was obtained after weighing, heating, melting and stirring.

[0102] On a glass substrate with a rubbed polyimide layer, the polymeric composition PL-1 was spin-coated at 1500 rpm. The coated glass substrate was placed on a hot plate at 60° C. for 10 minutes to achieve uniform horizontal alignment of the polymerizable composition. Then irradiate with ultraviolet light with a wavelength of 365nm, and the light intensity is 20mW / cm 2 , the irradiation time was 1 minute, and an o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com