Phase displacement film

A retardation film and norbornene technology, applied in polarizing elements and other directions, can solve the problems of difficulty in reflecting retardation, limitation of retardation compensation range of retardation film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

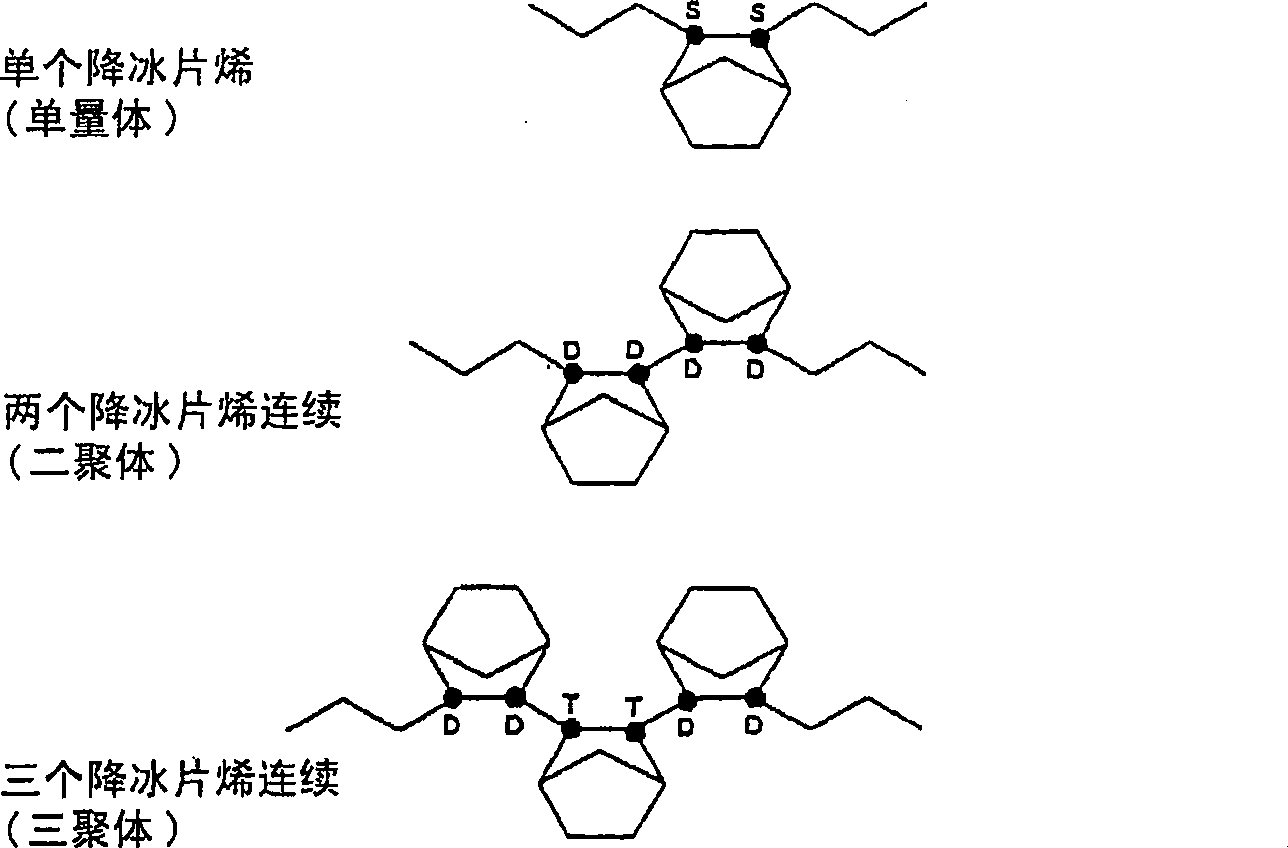

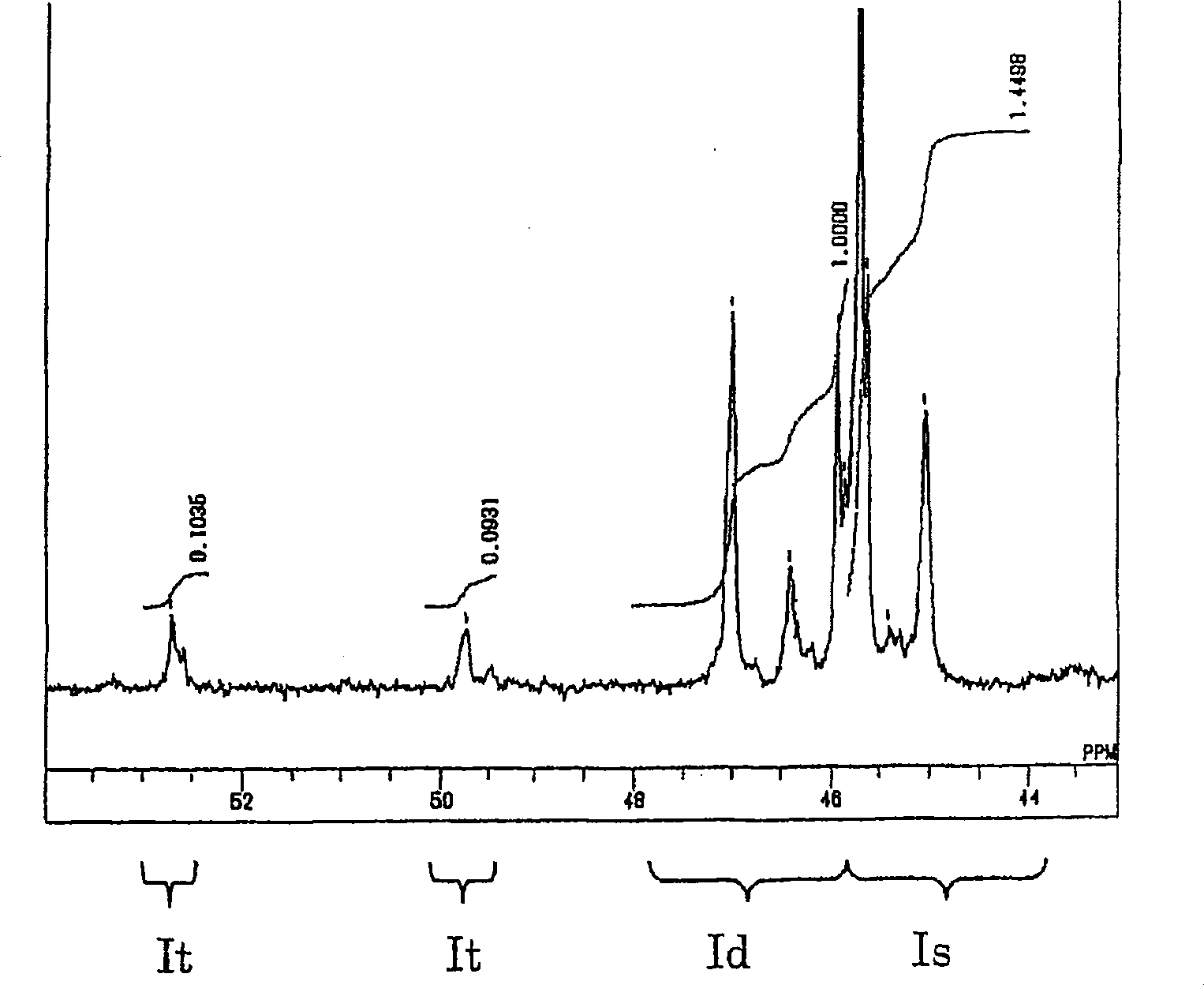

[0149] (1) Synthesis of norbornene-ethylene copolymer

[0150]In the continuous polymerization device, the concentration of norbornene is 2.95mol / L, the concentration of ethylene is 1.05mol / L, and the ratio of hydrogen to ethylene is 0.21×10 -3 The condition supplies norbornene, hydrocarbon solvent, ethylene and hydrogen. At the same time, a catalyst system is supplied to the reaction device, which consists of racemic-isopropylidene-bis(tetrahydroindenyl)zirconium dichloride as a catalyst, methylaluminoxane (10% toluene solution) as a cocatalyst constitute. The temperature of the reaction apparatus was maintained at 90°C. In the subsequent step, the solvent is removed by high temperature and reduced pressure. The melted copolymer was extruded in the form of a strand (strand), which was cut to obtain pellets with a length of 3 mm and a diameter of 2 mm. 0.6% of an antioxidant (trade name Irganox 1010, manufactured by Ciba Specialty Chemicals) and 0.4% of pentaerythritol tet...

Embodiment 2~4、 comparative example 1

[0154] A norbornene-ethylene copolymer was synthesized in the same manner as in Example 1 except that the synthesis conditions shown in Table 1 were used, and norbornene was obtained in the same manner as in Example 1 except that the obtained norbornene-based copolymer was used. Olefinic copolymer composition and raw film.

[0155]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| birefringence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com