Novel polymerization reaction vessel

A technology of polymerization reaction kettle and polymerization kettle, which is applied in chemical/physical/physical-chemical fixed reactors, etc., can solve the problems of easy sticking kettle, easy fouling of manholes, easy fouling, etc., so as to ensure the performance and use. Longevity, uniform and stable cooling water flow, and increased productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

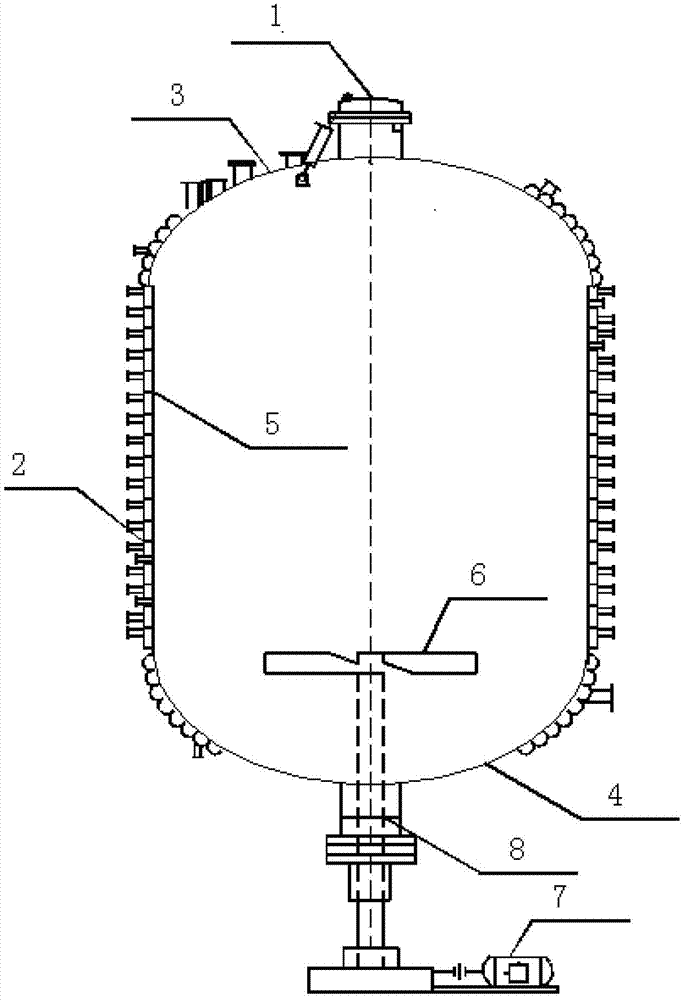

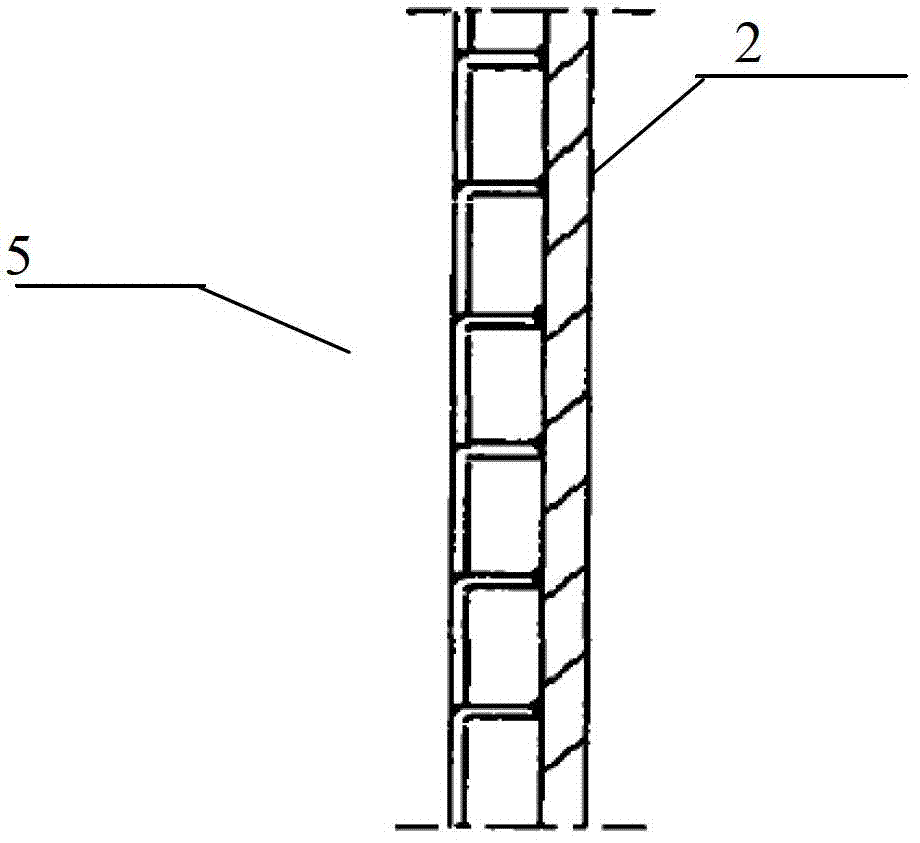

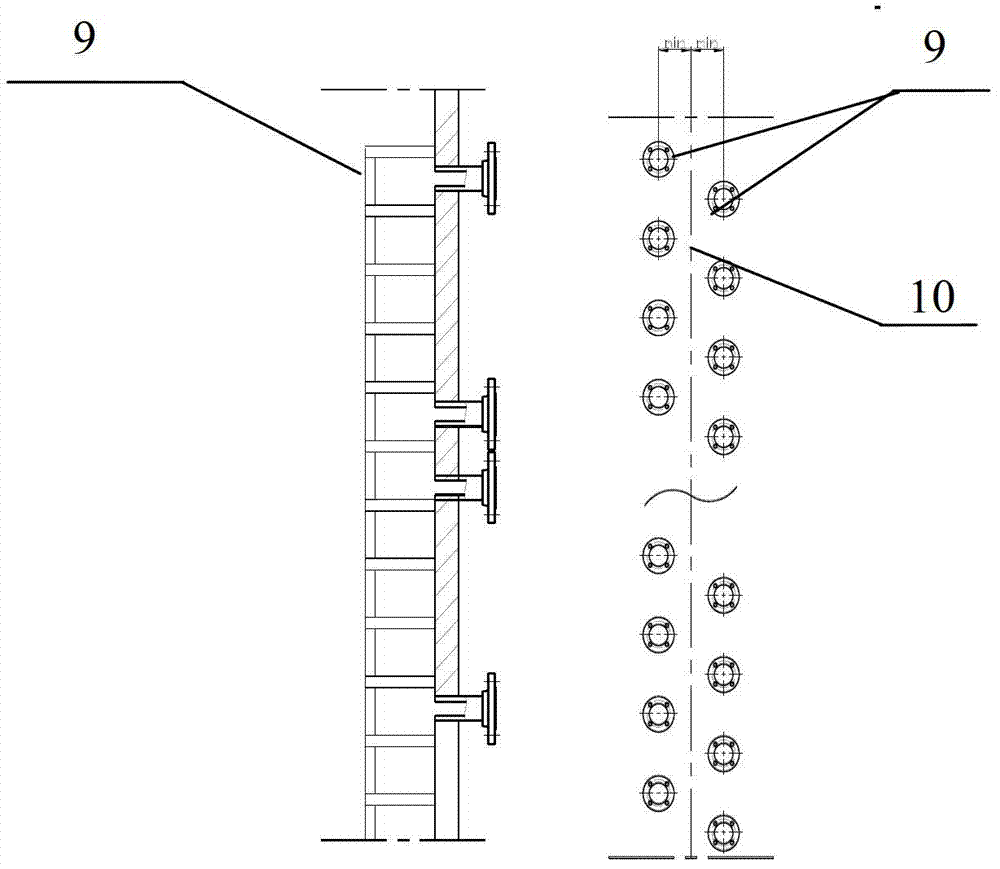

[0027] A new type of polymerization reaction kettle of the present invention comprises a tank top manhole 1, a kettle wall 2, an upper head 3, a lower head 4, an inner jacket 5, an agitator 6, an agitator motor 7 and an agitator transmission 8, Among them, the manhole 1 on the top of the kettle is directly set on the kettle body, and the short section is not provided to solve the problem that the short section of the manhole is easy to scale; the diameter of the kettle body is 4200mm-4400mm, and the height of the kettle body is 6900mm-8100mm.

[0028]The main design process is to first calculate the volume of the polymerization kettle according to the production capacity, determine the diameter and height-to-diameter ratio of the polymerization kettle, the number of nozzles, nozzle diameters and nozzle divisions of the polymerization kettle; carry out stress analysis and design according to the structure of the polymerization kettle, and determine The wall thickness of the barr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap