Catalyst for lowering N-vinyl-2-pyrrolidone in polyvinylpyrrolidone (PVP), and preparation method and application thereof

A technology of polyvinylpyrrolidone and vinylpyrrolidone, which is applied in the field of catalysts, can solve the problems of low production capacity, increased equipment investment, etc., and achieves the effects of low cost, industrialized production, and simple use method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

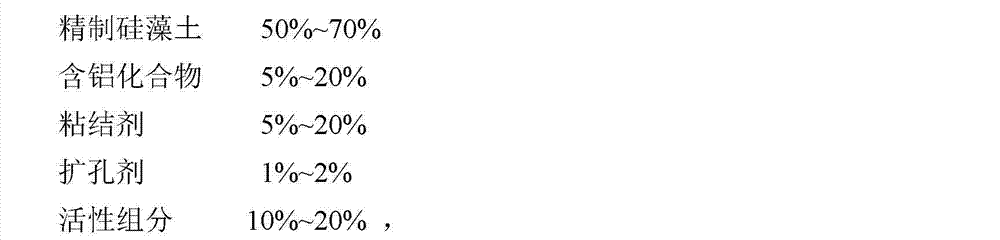

Method used

Image

Examples

Embodiment 1

[0029] According to the mass ratio of nitric acid and natural diatomite 1:1, measure nitric acid and natural diatomite with a concentration of 0.25N, soak the natural diatomite with nitric acid with a concentration of 0.25N at room temperature and normal pressure for 3 hours, and the soaking time expires Finally, solid-liquid separation, the separated diatomite was washed 3 times with deionized water, dried in the air, then put into an oven, and dried at normal pressure at 100°C for 12 hours to obtain powdery refined diatomite A.

Embodiment 2

[0031] According to the mass ratio of nitric acid and natural diatomite 2:1, measure nitric acid and natural diatomite with a concentration of 0.25N, soak the natural diatomite with nitric acid with a concentration of 0.25N at room temperature and normal pressure for 5h, and the soaking time expires Finally, solid-liquid separation, the separated diatomite was washed 5 times with deionized water, dried in the air, then put into an oven, and dried at 120°C under normal pressure for 10 hours to obtain powdery refined diatomite B.

Embodiment 3

[0033] According to the mass ratio of nitric acid and natural diatomite 3:1, measure nitric acid and natural diatomite with a concentration of 0.25N, soak the natural diatomite with nitric acid with a concentration of 0.25N at room temperature and normal pressure for 6 hours, and the soaking time expires Finally, solid-liquid separation, the separated diatomite was washed 6 times with deionized water, dried in the air, then put into an oven, and dried at normal pressure and 150°C for 6 hours to obtain powdery refined diatomite C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com