Environment-friendly cigarette pack flexible water-based printing ink production process

A technology of printing ink and production process, which is applied in the field of production process of environmentally friendly flexographic water-based printing ink for cigarette packaging, which can solve the problems of air pollution and carcinogenicity, and achieve the effect of good gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

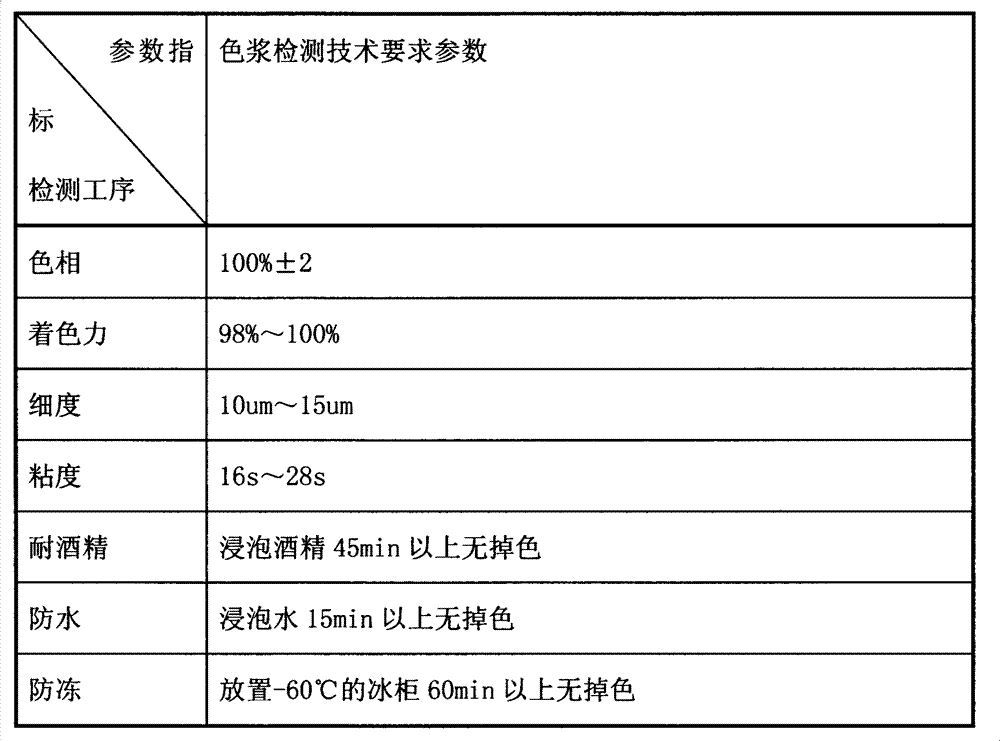

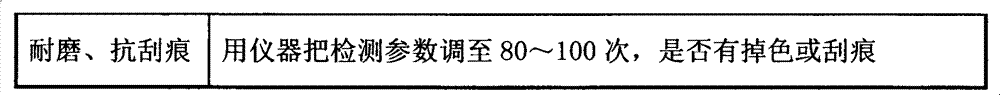

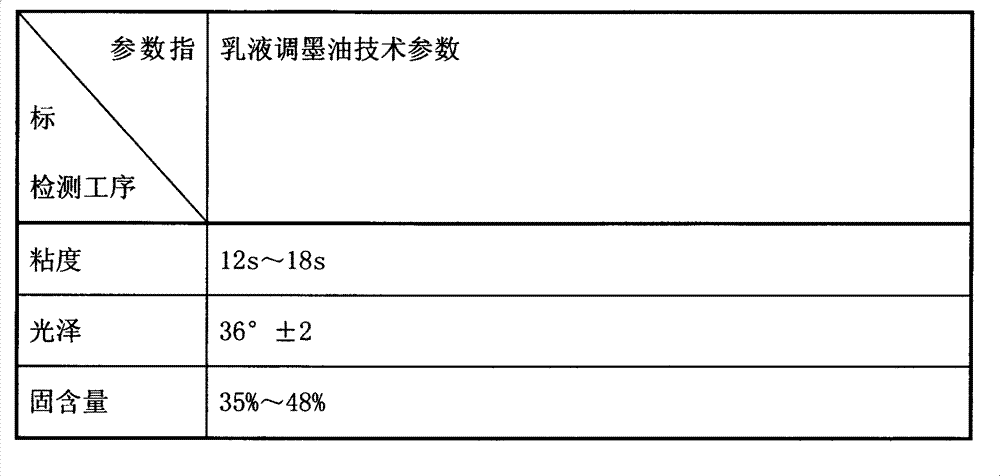

[0012] A production process of environmentally friendly flexographic water-based printing ink for cigarette packaging. The ink is prepared from a two-component coating agent, a temperature-varying pigment, an ordinary pigment, and a defoaming agent. The two-component coating agent includes petroleum Resin and a curing agent for curing the petroleum resin, the parts by weight of the raw materials are respectively 40-70 petroleum resin, 10-30 curing agent, 10-40 temperature-changing pigment, 0-20 ordinary pigment, and 2-8 defoaming agent;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com