Processes for production of synthetic naphtha

A manufacturing method and a technology for naphtha, which are used in the catalytic reforming of naphtha, the preparation of liquid hydrocarbon mixtures, the petroleum industry, etc. Heat and unstable operation stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

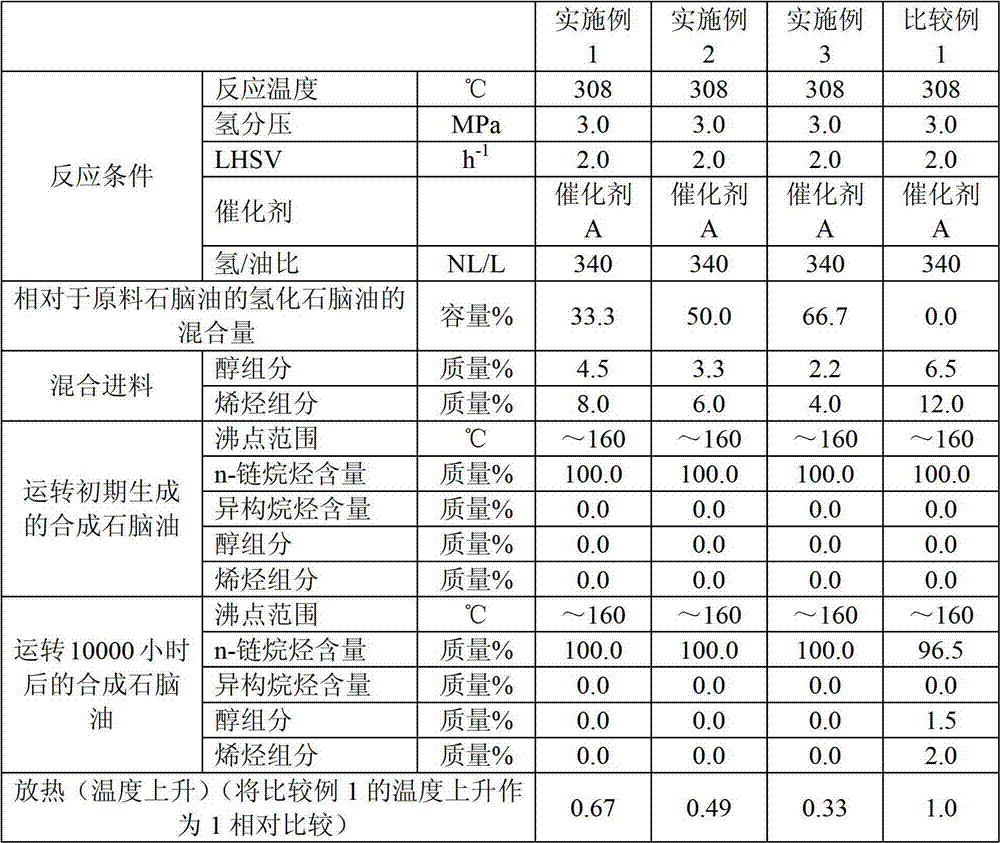

Embodiment 1

[0086] (hydrofinishing of naphtha fractions)

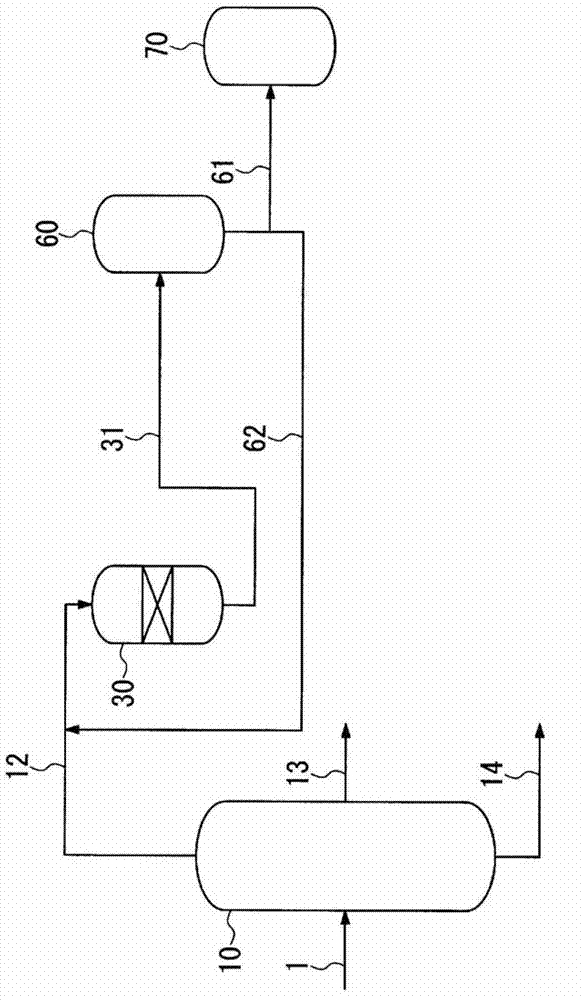

[0087] Fill hydrogenation catalyst A (150ml) in figure 1 In the flow-through reactor of the fixed bed, that is, the hydrotreating unit 30, the naphtha fraction (raw naphtha) obtained as above is supplied from the top of the reactor 30 at a rate of 300ml / h, Hydrotreating was carried out under the above reaction conditions.

[0088] That is to say, relative to the naphtha fraction, hydrogen is supplied from the top of the tower at a hydrogen / oil ratio of 340NL / L, and the back pressure valve is adjusted to stabilize the pressure of the reaction tower at an inlet pressure of 3.0MPa (hydrogen partial pressure) for hydrogenation. refined. The reaction temperature at this time was 308°C.

[0089] The naphtha fraction hydrotreated in the hydrotreating unit 30 is stored in a storage tank 70 from a line 61 via a stabilization column 60 from a line 31 .

[0090] Here, a part of the obtained hydrogenated naphtha fraction is recycled from ...

Embodiment 2

[0094] (hydrofinishing of naphtha fractions)

[0095] Catalyst A (150ml) is filled in a flow-through reactor of a fixed bed, that is, a hydrotreating unit 30, and the naphtha fraction (raw naphtha ), under hydrogen flow, under the following reaction conditions for hydrogenation treatment.

[0096] That is to say, relative to the naphtha fraction, hydrogen is supplied from the top of the tower at a hydrogen / oil ratio of 340NL / L, and the back pressure valve is adjusted to stabilize the pressure of the reaction tower at an inlet pressure of 3.0MPa (hydrogen partial pressure) for hydrogenation. refined. The reaction temperature at this time was 308°C.

[0097] Here, the obtained hydrogenated naphtha fraction was mixed with 50.0% by volume relative to the raw material naphtha, and after obtaining the mixed feed having the properties shown in Table 2, it was carried out under the same conditions as the above-mentioned hydrotreating conditions. Processing to obtain synthetic napht...

Embodiment 3

[0100] (hydrofinishing of naphtha fractions)

[0101] Catalyst A (150ml) is filled in a flow-through reactor of a fixed bed, that is, a hydrotreating unit 30, and the naphtha fraction (raw naphtha ), under hydrogen flow, under the following reaction conditions for hydrogenation treatment.

[0102] That is to say, relative to the naphtha fraction, hydrogen is supplied from the top of the tower at a hydrogen / oil ratio of 340NL / L, and the back pressure valve is adjusted to stabilize the pressure of the reaction tower at an inlet pressure of 3.0MPa (hydrogen partial pressure) for hydrogenation. refined. The reaction temperature at this time was 308°C.

[0103] Here, the obtained hydrogenated naphtha fraction was mixed at 66.7% by volume with respect to the raw naphtha, and after obtaining the mixed feed having the properties shown in Table 2, it was carried out under the same conditions as the above-mentioned hydrotreating conditions. Processing to obtain synthetic naphtha. Ta...

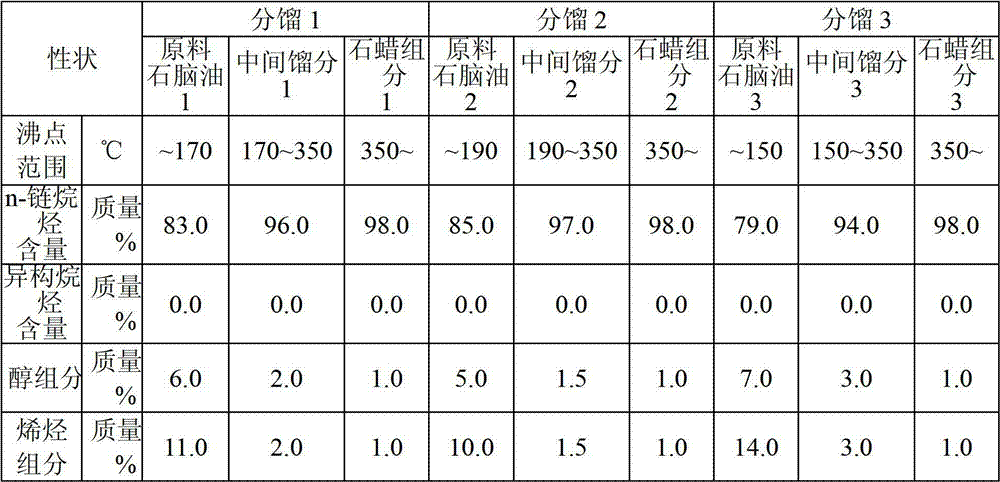

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com