Heat treatment method for martensitic stainless steel forging module

A technology of martensitic stainless steel and heat treatment method, which is applied in the field of heat treatment of martensitic stainless steel forging modules, and can solve the problems of low degree of austenitization and poor corrosion resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

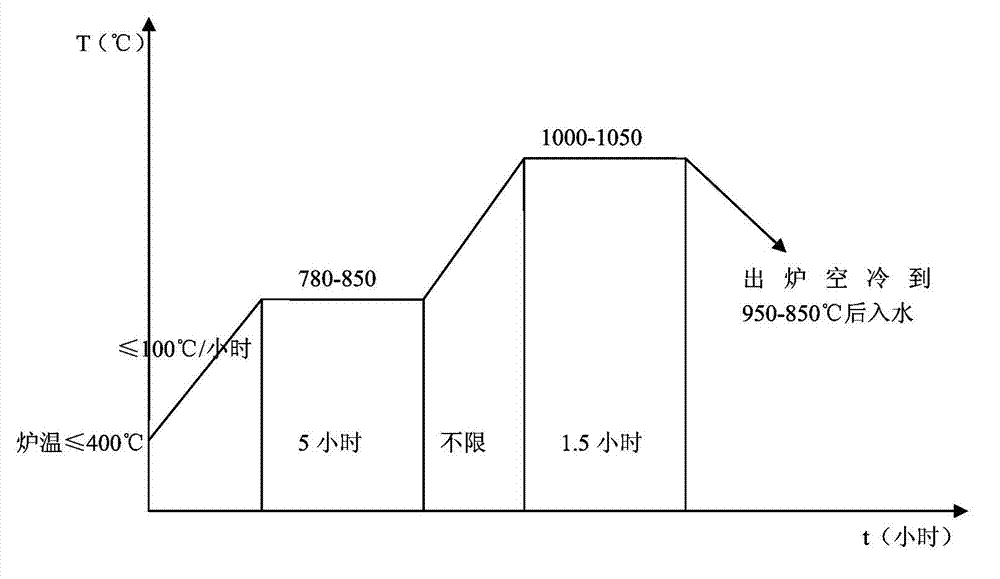

Method used

Image

Examples

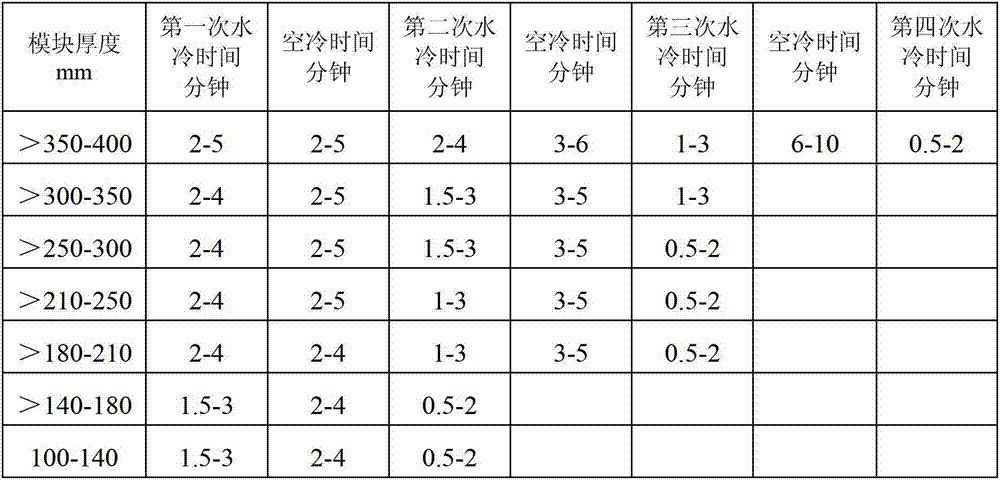

Embodiment 1

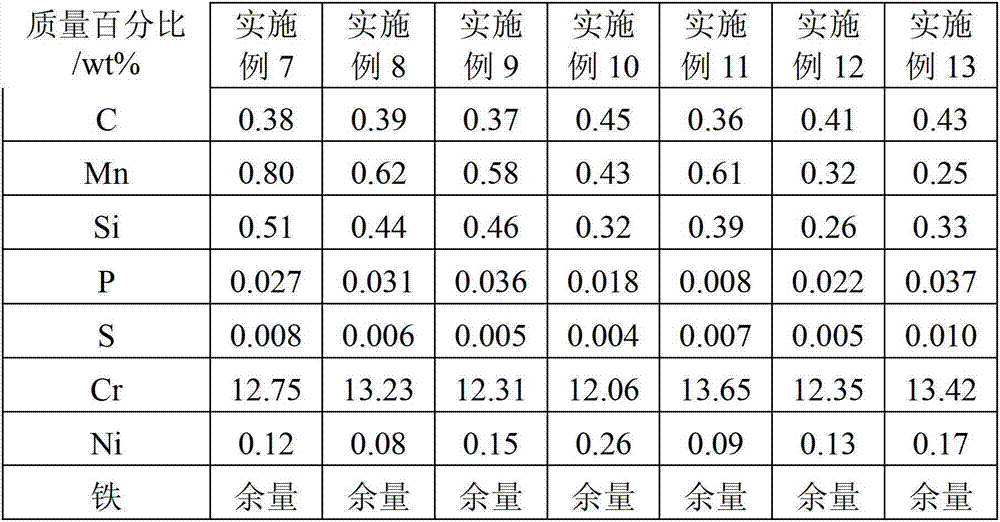

[0040] A kind of 40Cr13 martensitic stainless steel forging module is carried out water air gap cooling and quenching heat treatment, wherein, obtain 40Cr13 martensitic stainless steel forging module by following steps:

[0041] a. Smelting: primary smelting in electric furnace, ladle refining in LF heating furnace and vacuum degassing process in VD furnace. 0.010%, Cr 12.0%, Ni 0.11%, the balance is iron and unavoidable impurities; cast into 5t octagonal ingot after tapping;

[0042] b. Forging module: send 5t octagonal ingots to the heating furnace at a temperature of ≥300°C, and after heating to 1150°C, use a 2000t press to forge a module with a thickness of 100mm and a width of 300mm. The forging ratio is ≥4, and after spheroidization Annealing, polishing or turning, milling and local grinding to remove surface defects, and after passing the GB / T4162-91 standard B-level ultrasonic flaw detection inspection, cold sawing end faces are cut into 1.0-8.0 meters long according t...

Embodiment 2

[0048] A kind of 40Cr13 martensitic stainless steel forging module is carried out water air gap cooling and quenching heat treatment, wherein, obtain 40Cr13 martensitic stainless steel forging module by following steps:

[0049] a. Smelting: primary smelting in electric furnace, ladle refining in LF heating furnace and vacuum degassing process in VD furnace. 0.002%, Cr 14.00%, Ni 0.32%, the balance is iron and unavoidable impurities; cast into 40t octagonal ingot after tapping;

[0050] b. Forging module: send 40t octagonal ingot to the heating furnace at a temperature of ≥300°C, heat it to 1240°C and use a 4000t press to forge it into a module with a thickness of 400mm and a width of 1300mm. The forging ratio is ≥4. Annealing, polishing or turning, milling, and local grinding to remove surface defects, and after passing the GB / T4162-91 standard B-level ultrasonic flaw detection inspection, the cold sawing end face is cut into 1.0-8.0 meters long according to the order require...

Embodiment 3

[0056] A kind of 40Cr13 martensitic stainless steel forging module is carried out water air gap cooling and quenching heat treatment, wherein, obtain 40Cr13 martensitic stainless steel forging module by following steps:

[0057] a. Smelting: primary smelting in electric furnace, ladle refining in LF heating furnace and vacuum degassing process in VD furnace. 0.003%, Cr 14.00%, Ni 0.09%, the balance is iron and unavoidable impurities; cast into 19t octagonal ingot after tapping;

[0058] b. Forging module: Send 19t octagonal ingots to the heating furnace at a temperature of ≥300°C, and after heating to 1220°C, use a 4,000t press to forge a module with a thickness of 280mm and a width of 800mm. The forging ratio is ≥4, and after spheroidization Annealing, polishing or turning, milling, and local grinding to remove surface defects, and after passing the GB / T4162-91 standard B-level ultrasonic flaw detection inspection, the cold sawing end face is cut into 1.0-8.0 meters long acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com