Method of controlling overflow substance in reduction process of vanadium ferrotitanium fine powder

A technology of vanadium-titanium ferro-titanium fine powder, which is applied in the field of controlling the overflow during the reduction process of vanadium-titanium ferro-titanium fine powder, and can solve the problems that the reduction process cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

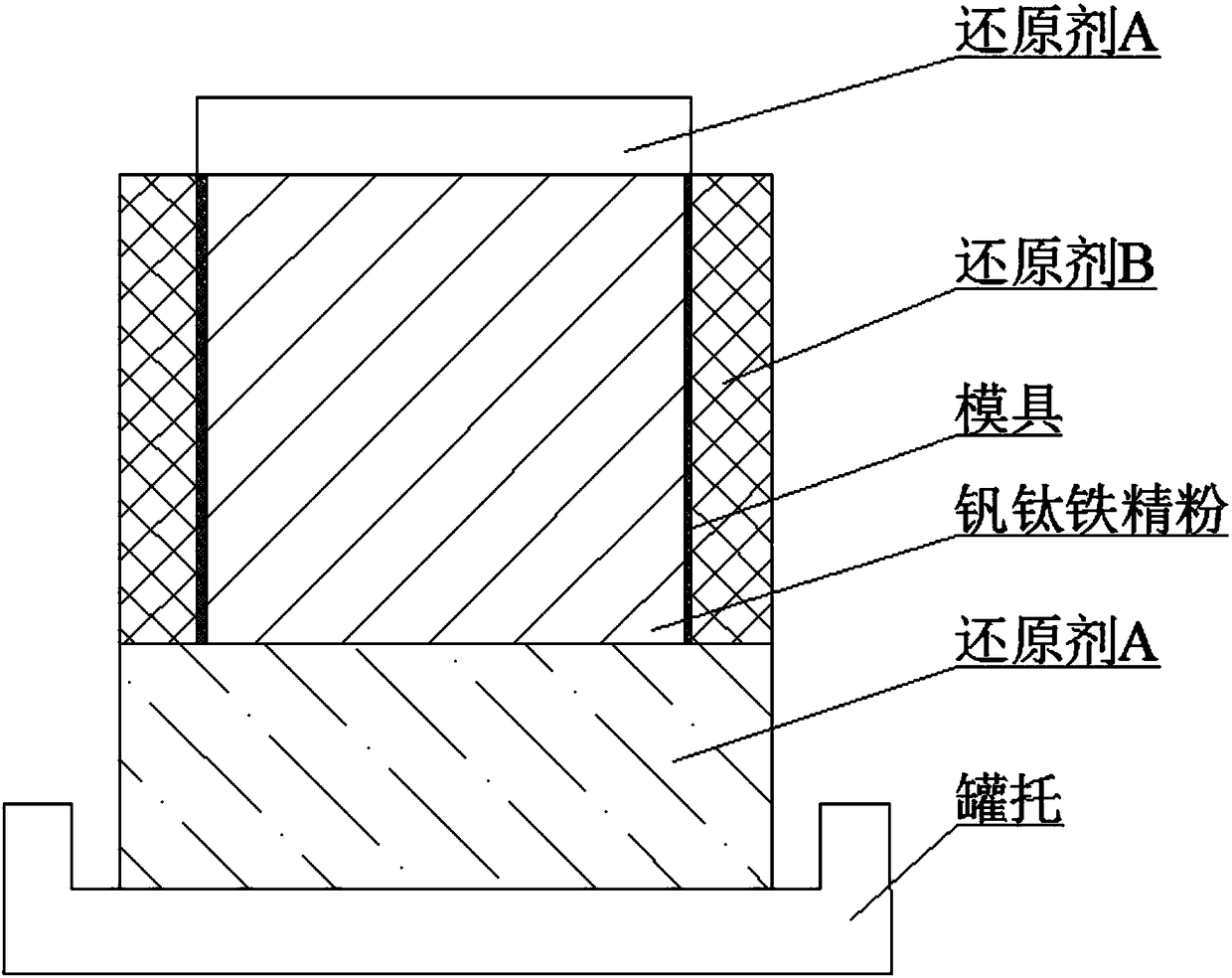

[0011] A refractory tank with an inner diameter of 300 mm and a height of 300 mm is seated on the tank support. The tank support has a tank support body, and a square bracket with a side length of 320 mm and a depth of 20 mm is provided on the top surface of the tank support body. Put a layer of reducing agent A with a thickness of 100mm in the tank, put a barrel-shaped mold with a wall thickness of 2mm, an outer diameter of 280mm, and a height of 200mm in the refractory tank, fill the mold with vanadium-titanium iron fine powder, Put reducing agent B between the tank body and the refractory tank to form a ring-shaped reducing agent layer with a thickness of 20mm, pull out the mold, and cover a layer of reducing agent A with a thickness of 20mm on the surface of vanadium-titanium iron fine powder. The reducing agent A is A mixture of metallurgical coke, semi-coke and dolomite with a mass ratio of 50:40:15, the reducing agent B is semi-coke, and the tank support and refractory t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com