Full circle swinging telescopic gap bridge

A telescopic, full-rotation technology, used in ships, cargo handling equipment, passenger handling equipment, etc., can solve the problems of poor safety and reliability of material transportation, slow personnel transfer, and low work efficiency, and achieve safe and fast personnel transfer. Reliable and convenient transportation and the effect of reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

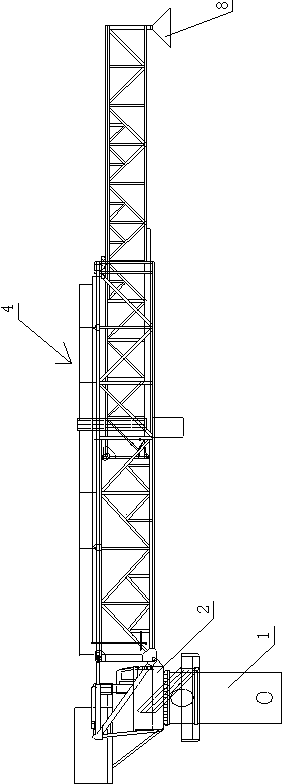

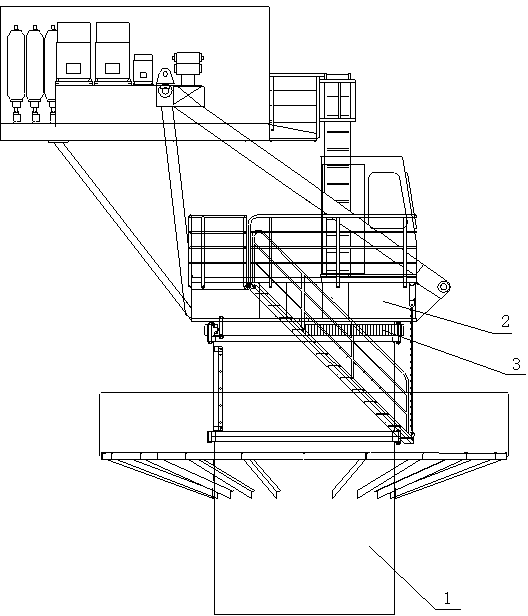

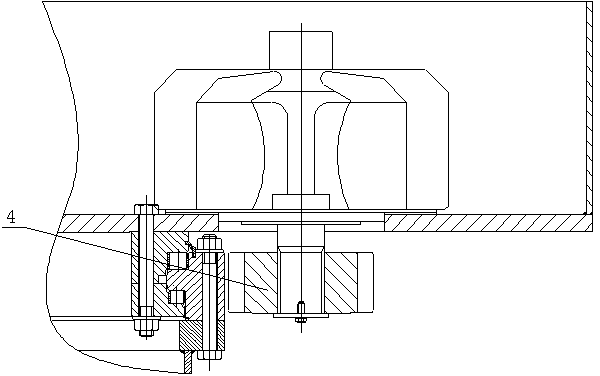

[0022] see Figure 1 to Figure 7 , the full-rotation telescopic bridge that the present invention relates to, it comprises base frame 1, and described base frame 1 is fixed on the deck platform of marine living platform, and above described base frame 1 is provided with slewing support 2, and described base frame 1 It is connected with the slewing support 2 through the external tooth slewing support 3, and the external tooth slewing support 3 cooperates with the hydraulic motor pinion 4, and the hydraulic motor pinion 4 is powered by the hydraulic motor, so that the slewing support 2 carries The top fittings rotate together to realize the rotation of the full-rotation telescopic bridge.

[0023] The slewing support 2 is provided with a luffing cylinder 5 and an oblique support 6, the lug plate at the tail end of the cylinder body of the luffing cylinder 5 is hinged with the top of the slewing support 2, and the piston rod of the luffing cylinder 5 is connected to the bridge 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com