External displacement sensor

A displacement sensor and outer sleeve technology, applied in the direction of fluid pressure actuating devices, etc., can solve the problems of shortened sensor life, large downtime, and displacement sensor damage, achieve high detection accuracy and response frequency, and meet the needs of position control. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

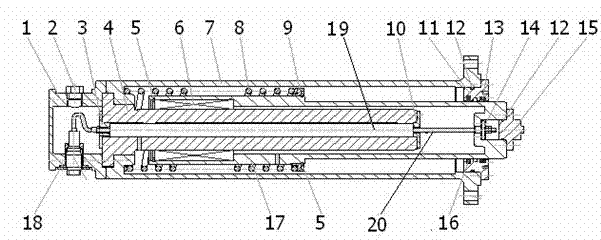

[0017] Embodiment 1 is a schematic diagram of the installation of a LVDT type linear displacement sensor.

[0018] Such as figure 1 As shown, a kind of external displacement sensor, comprises: linear bearing 6, outer sleeve 7, spring 8, slide guide rod 4, displacement sensor measuring rod 19 and moving sleeve 17, displacement sensor measuring rod 19 is in sliding guide rod 4 Inside, the sliding guide rod 4 is inside the outer sleeve 7, the sliding guide rod 4 and the outer sleeve 7 are coaxially fixed by screws, and there is an annular space for placing the linear bearing 6 between the moving sleeve 17 and the sliding guide rod 4, and the linear bearing 6 In the annular space; the spring 8 is fixed by the spring seat 9 in the inner hole of the outer sleeve 7, the retaining ring 5 is installed on the left end of the moving sleeve 17, the spring seat 9 is installed between the moving sleeve 17 and the outer sleeve 7, and the When the spring 8 is loaded into the moving sleeve 17...

Embodiment 2

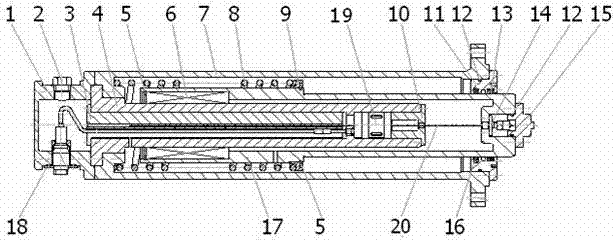

[0024] Embodiment 2 is a schematic diagram of the installation structure of the SONY MD50 series magnetic ruler and magnetic head.

[0025] figure 2 As shown, the difference from Embodiment 1 is that the shapes of the inner hole of the sliding guide rod 4, the fixed gland 3 on the outlet side and the flange gland 10 are different, which is only due to the different shapes of the detection heads of the two types of sensors.

[0026] The principle of the present invention is: by fixing the measuring rod (magnetic head) of the displacement sensor in the sliding guide rod, and the iron core (magnetic ruler) of the displacement sensor is installed in the moving sleeve through the flange type fixing assembly, the sensor position detection process The middle moving sleeve and the sliding guide rod produce concentric relative sliding along the axis, and an air communication hole is set on each of the moving sleeve and the sliding guide rod to ensure that the main body will not crawl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com