An integral valve seat nested flat gate valve

A flat gate valve, nested technology, applied in the direction of sliding valve, valve details, valve device, etc., can solve the problems of difficult to use flat gate valve, high pressure shut-off valve leakage, difficult pipeline maintenance, etc., to achieve better cut-off effect and ensure parallel degree and vertical requirements, the effect of highlighting substantive features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

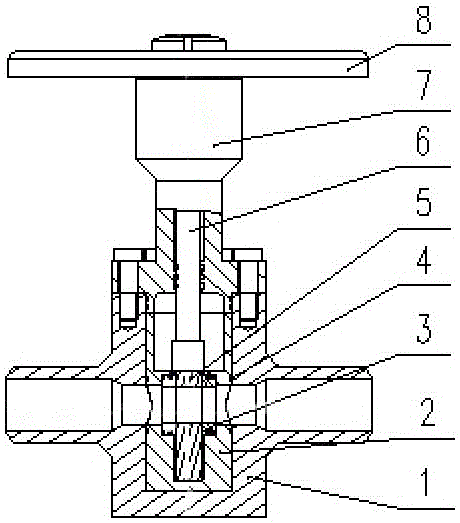

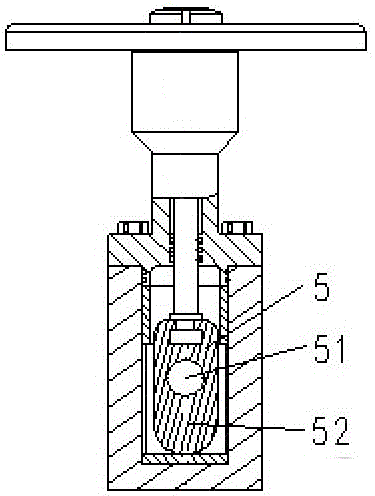

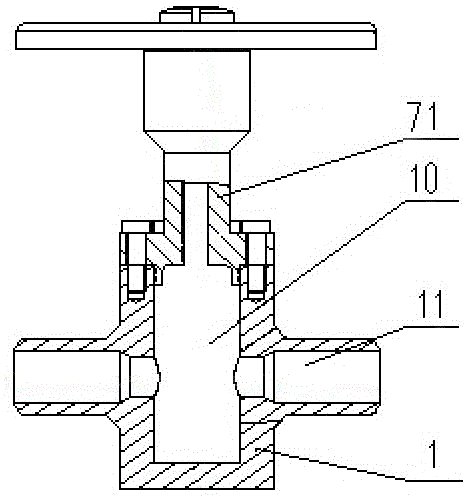

[0017] An integral valve seat nested flat gate valve, including a valve body 1, a valve seat sleeve 2, a valve seat assembly 3, a valve plate 5, a valve stem 6, a handwheel 8 and a bracket assembly 7, the valve seat assembly includes a valve Seat 31, the bracket assembly includes a bracket flange cover 71, the valve body 1 is provided with a medium flow channel 11 for the medium to enter and flow out, and the bracket flange cover 71 is arranged on the upper part of the valve body and forms a second valve body with the valve body 1. A cavity 10, the valve seat sleeve 2 is nested in the first cavity 10, the first cavity matches the valve seat sleeve, the valve seat sleeve 2 is provided with a second cavity 9 and The media channel of the valve body is matched with the connected medium channel 21, and a stepped cylindrical cavity 22 is provided in the medium channel 21. The diameter of the cylindrical cavity is larger than that of the medium channel 21, and the cylindrical cavity p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com