8-analogue-shaped soil uniaxial tensile tester

A uniaxial tensile tester technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problem that the tensile stress-strain curve cannot be measured, the loading process is affected by human factors, and the sample breaking point Large randomness of position and other problems, to achieve the effect of low cost, uniform force and reliable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

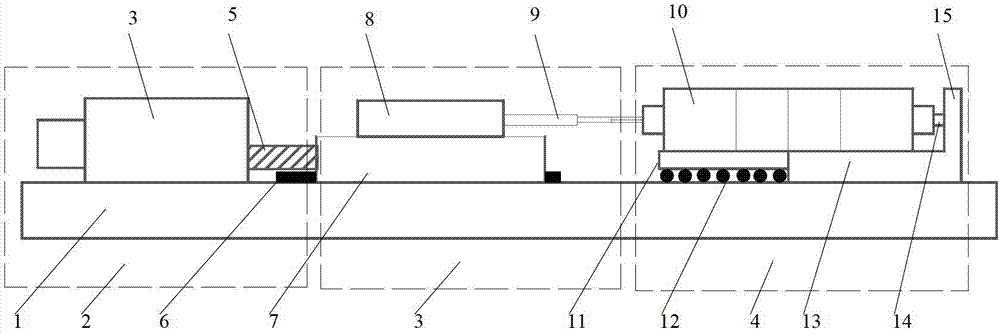

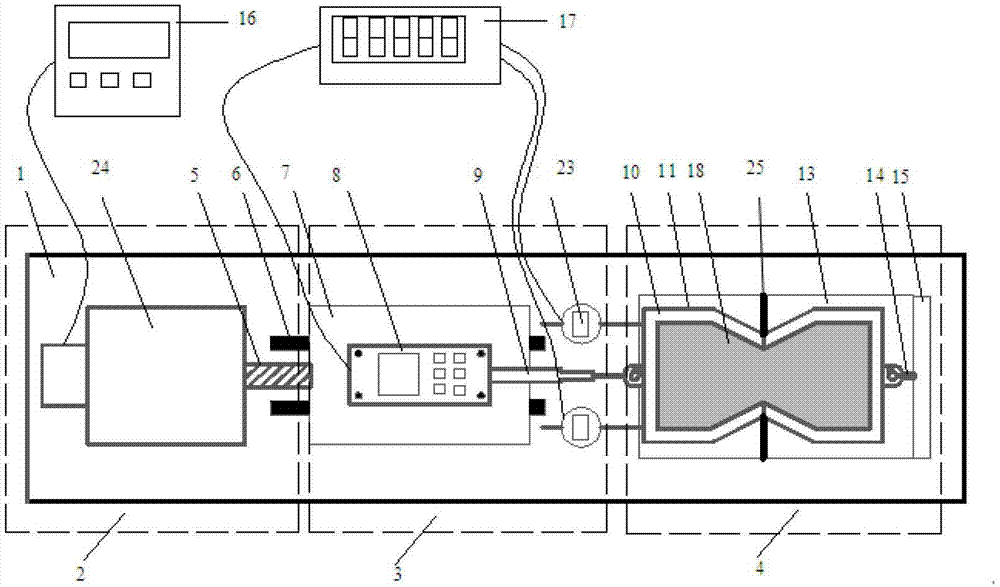

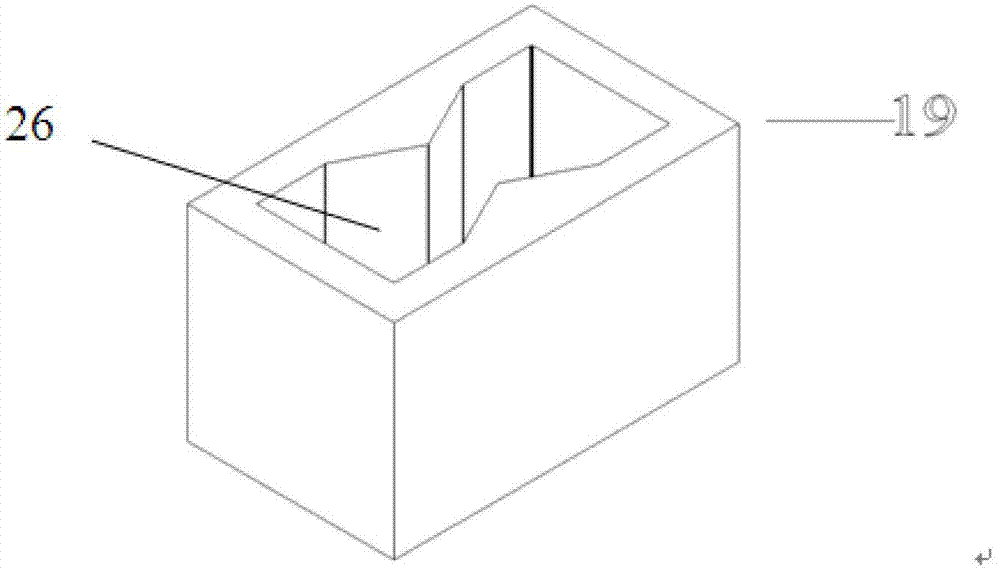

[0030] Example: as figure 1 As shown, the present invention includes a main body platform 1, a loading system 2, a measuring system 3 and a sample positioning and stretching system 4, and the loading system 2, the measuring system 3 and the sample positioning and stretching system 4 are all installed on the main body platform 1 .

[0031] like figure 1 figure 2 As shown, the loading system 2 includes a motor 24, a rigid transmission shaft 5 and a control box 16, and the measuring system 3 includes a guide rail 6, a slide rail guide block 7, a tension sensor 8, a displacement sensor 23, a data collector 17 and a rigid Connecting rod 9, the sample positioning and stretching system 4 includes an "8"-like retractor 10, a rolling platform 11, a ball 12, a fixed platform 13, a rigid fixed rod 14 and a rear fixed baffle 15, the motor 24 The control box 16 is connected with the control box 16 through wires. The function of the control box 16 is to control the power supply a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com