Motion parameter measuring system calibration method and motion parameter measuring system based on position sensitive sensor

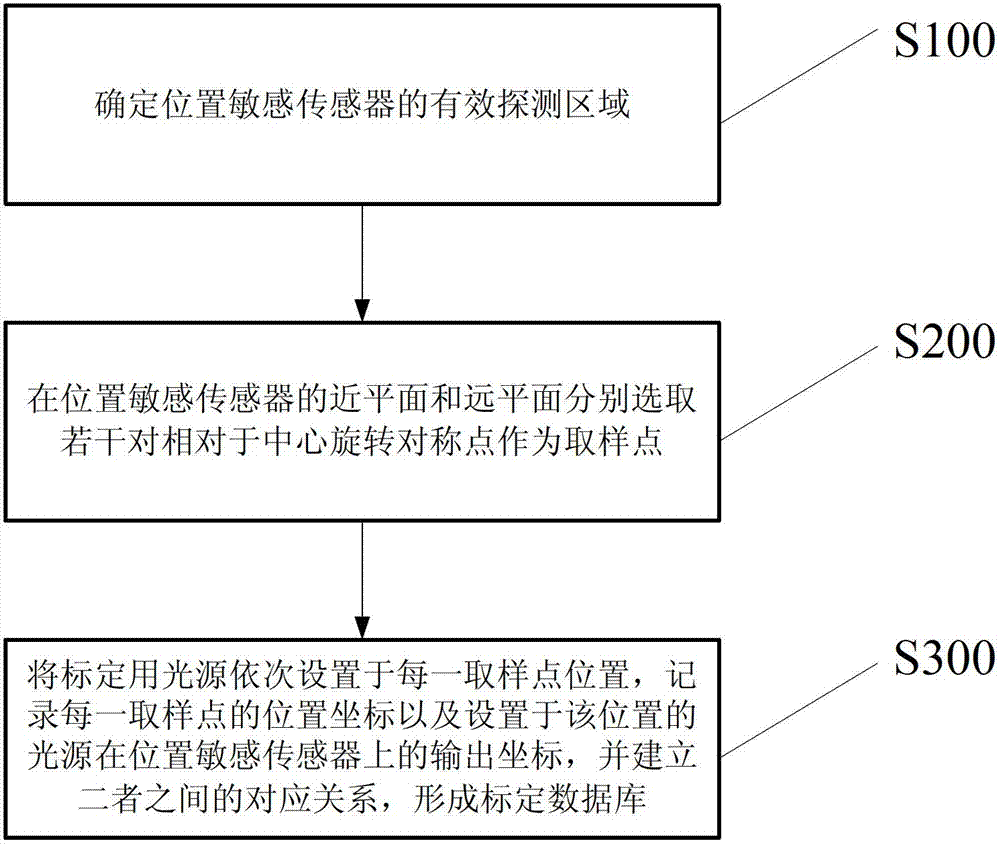

A technology of sensitive sensor and measurement system, applied in the field of measurement, can solve the problem of calculating the relationship between the output signal of the device and the coordinates of the actual spatial position, and achieve the effect of a high degree of automation and a simple method of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

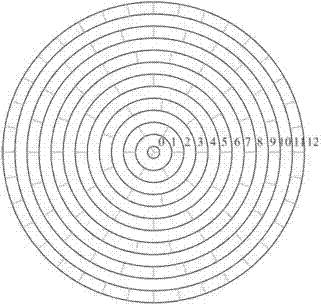

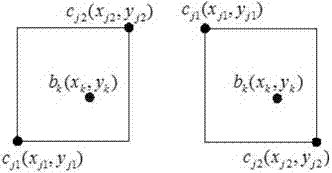

[0056] Taking the rotationally symmetrical rigid body nutation measurement system of linear motion as an example, the calibration method of the measurement system based on PSD is described.

[0057] The nutation of a rigid body refers to the angle between the main trajectory of the rigid body and the axis of the instantaneous rigid body during the linear motion of the rigid body, such as Figure 5 shown.

[0058] The structure of the rigid body nutation measurement system is as follows: Figure 6 As shown, 17 represents the rigid body to be measured in this system, and the arrow points to the motion direction of the rigid body. Install two infrared LED indicator light sources at both ends of the rigid body, such as indicator light source 15 and indicator light source 16 in the figure. The advantage of choosing infrared LED as indicator light source is that it can avoid visible light interference to a certain extent. PSD6 and PSD7 are used to receive the light signal correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com