Microscope gain control system

A gain control and microscope technology, applied in the field of microscopy, can solve the problems of high price and cannot meet the needs of popularization, and achieve the effects of low price, accurate and reliable focusing and zooming, and easy system construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

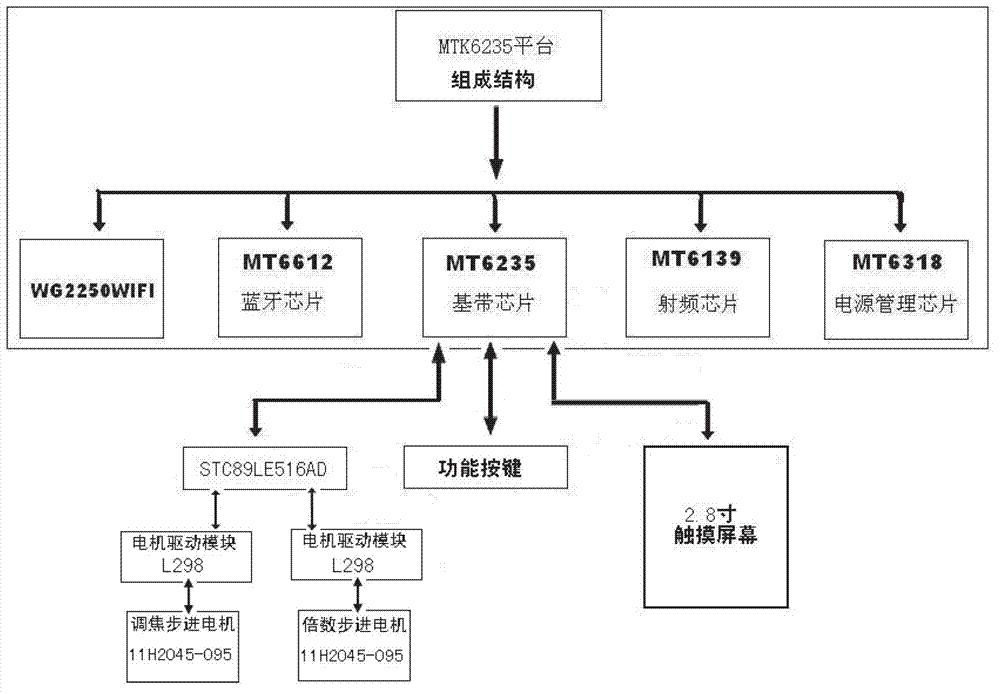

[0011] A microscope gain control system such as figure 1 As shown, it is mainly composed of MTK control platform, single-chip microcomputer control unit, function keys, display screen, at least one focusing motor drive unit, at least one magnification motor drive unit, at least one focus motor, at least one magnification motor, at least one The focusing gear is composed of at least one scaling gear. The MTK control platform is equipped with interconnected WIFI chips, Bluetooth chips, baseband chips, radio frequency chips and power management chips. The function keys and the display screen are connected to the baseband chip in the MTK control platform. The baseband chip in the MTK control platform is connected with the input end of the single-chip microcomputer control unit through the serial port. The output end of the single-chip microcomputer control unit is divided into at least 2 paths, one of which is connected to a focusing motor through a focusing motor drive unit, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com