Pixel driving circuit

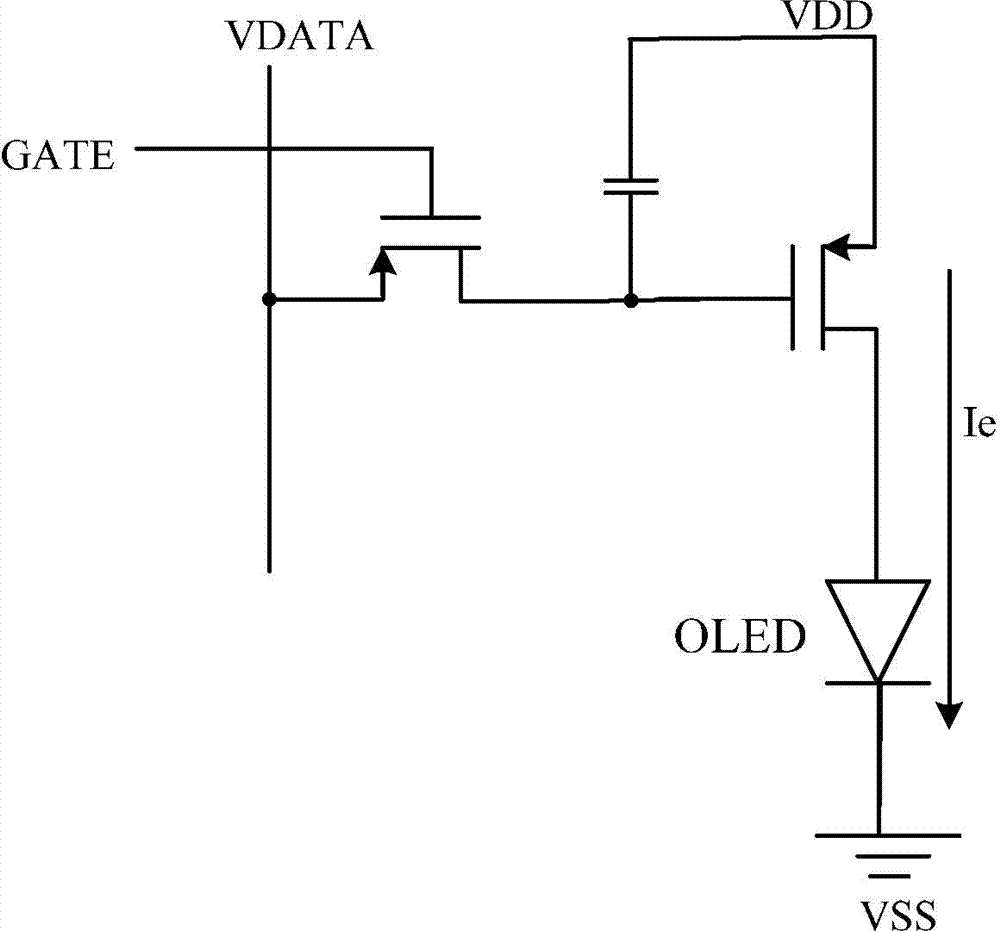

A pixel drive circuit and capacitor technology, applied in the field of pixel circuits, can solve the problems of different brightness, the effect of screen consistency, pixel brightness inconsistency, etc., to achieve consistency improvement, improve aesthetics and competitiveness, and uniform screen brightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

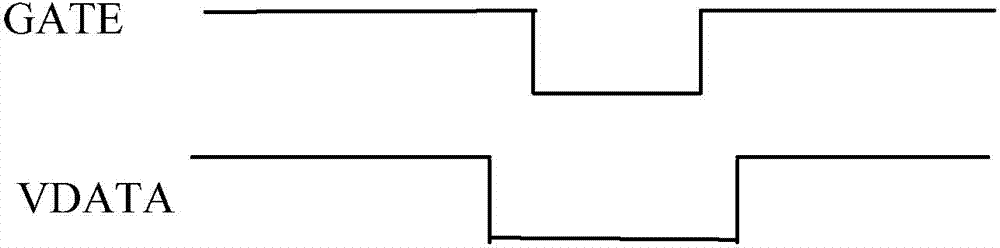

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate a further understanding of the structure and achieved effects of the present invention, preferred embodiments are described in detail below in conjunction with the accompanying drawings.

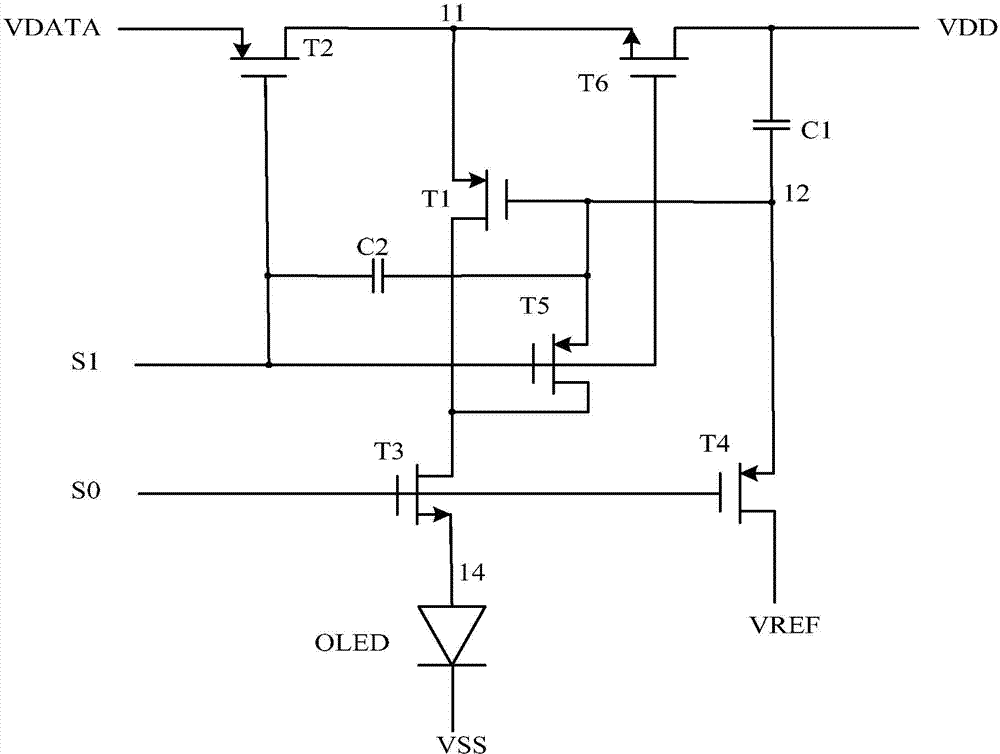

[0021] 3 is a schematic diagram of a pixel driving circuit of an active matrix organic light emitting display according to the present invention. The pixel driving circuit includes a first scanning line S0, a second scanning line S1 and a data line VDATA. The first scanning line S0 is connected to To the gate of an N-channel TFT transistor T3 and the gate of a P-channel TFT transistor T4, the second scanning line S1 is connected to the gate of a P-channel TFT transistor T5 and the gate of a P-channel TFT transistor T2 pole, the gate of an N-channel TFT transistor T6 and one end of a capacitor C2; the data line VDATA is connected to the source of the TFT transistor T2; the source of the TFT transistor T4 is connected to a reference voltage line VREF, and the TFT t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com